city17

Established Member

Hi all, I had this idea that it might be useful to have a specific "3D printing for woodworking" thread.

I noticed there are more and more woodworkers with a 3D printer nowadays, so having a place to find and share good designs specifically for woodworking might be helpful. Would be easier than searching through the countless designs on Thingiverse... Let me know what you think (or if I missed an existing thread like this).

To start off I'll share three designs I made recently, which are bench dogs, a planing stop, and a dust port adapter.

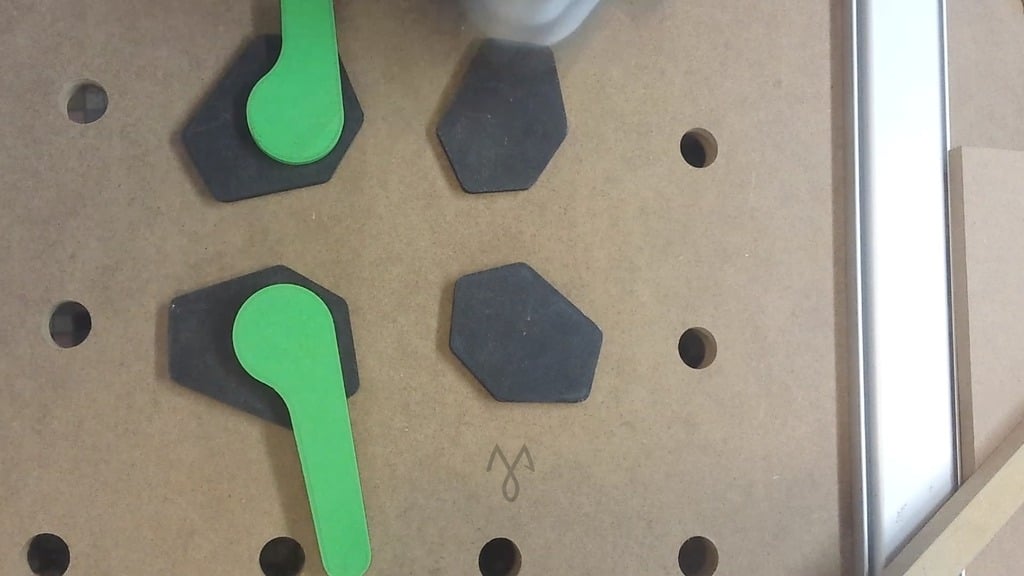

Bench Dog

Download STL file

More images of the Bench Dog.

This bench dog is a little different than ordinary ones, because it has a hole which fits M6 bolts. This allows you to mount anything with an M6 thread in your dog holes.

A good example of this is that you can use T-Track type clamps as a holdfast on your workbench. Currently if you want strong grip, you'll have to mount the bench dog from underneath the workbench, but maybe with a textured surface or if it were a little longer, it might also clamp with enough force from the top.

The cap on these bench dogs is removable and you can use them in conjunction with the planing stop below. So they're a bit more multifunctional than regular bench dogs.

Planing Stop

Download STL files (includes bench dogs).

More images and a video of the planing stop.

This planing stop uses the same bench dogs as above. You can slide them left and right, so you can use the planing stop anywhere there are two dog holes near each other. One added benefit of a 3D printed planing stop is that you don't have to worry about damaging your plane or blade, which is a downside of a metal planing stop.

If you'd like to make it longer or shorter, you can just scale it length-wise in your slicing software.

Dust Port Adapter for Makita Vacuum to Elektra Beckum HC260

Download link for the dust port adapter.

The last one is a little more specific, but maybe there are people here with the same setup. It's a dust port adapter for the Makita VC2512L vacuum to the Elektra Beckum HC 260 planer thicknesser.

It might actually fit some other machines as well, but that would be a bit of a coincidence. I've added a STEP file as well so you can adjust the inner/outer dimensions of both sides of the adapter. Using a normal vacuum with a planer thicknesser isn't ideal, but works reasonably well for smaller boards.

I noticed there are more and more woodworkers with a 3D printer nowadays, so having a place to find and share good designs specifically for woodworking might be helpful. Would be easier than searching through the countless designs on Thingiverse... Let me know what you think (or if I missed an existing thread like this).

To start off I'll share three designs I made recently, which are bench dogs, a planing stop, and a dust port adapter.

Bench Dog

Download STL file

More images of the Bench Dog.

This bench dog is a little different than ordinary ones, because it has a hole which fits M6 bolts. This allows you to mount anything with an M6 thread in your dog holes.

A good example of this is that you can use T-Track type clamps as a holdfast on your workbench. Currently if you want strong grip, you'll have to mount the bench dog from underneath the workbench, but maybe with a textured surface or if it were a little longer, it might also clamp with enough force from the top.

The cap on these bench dogs is removable and you can use them in conjunction with the planing stop below. So they're a bit more multifunctional than regular bench dogs.

Planing Stop

Download STL files (includes bench dogs).

More images and a video of the planing stop.

This planing stop uses the same bench dogs as above. You can slide them left and right, so you can use the planing stop anywhere there are two dog holes near each other. One added benefit of a 3D printed planing stop is that you don't have to worry about damaging your plane or blade, which is a downside of a metal planing stop.

If you'd like to make it longer or shorter, you can just scale it length-wise in your slicing software.

Dust Port Adapter for Makita Vacuum to Elektra Beckum HC260

Download link for the dust port adapter.

The last one is a little more specific, but maybe there are people here with the same setup. It's a dust port adapter for the Makita VC2512L vacuum to the Elektra Beckum HC 260 planer thicknesser.

It might actually fit some other machines as well, but that would be a bit of a coincidence. I've added a STEP file as well so you can adjust the inner/outer dimensions of both sides of the adapter. Using a normal vacuum with a planer thicknesser isn't ideal, but works reasonably well for smaller boards.