chris_d

Established Member

Dear all,

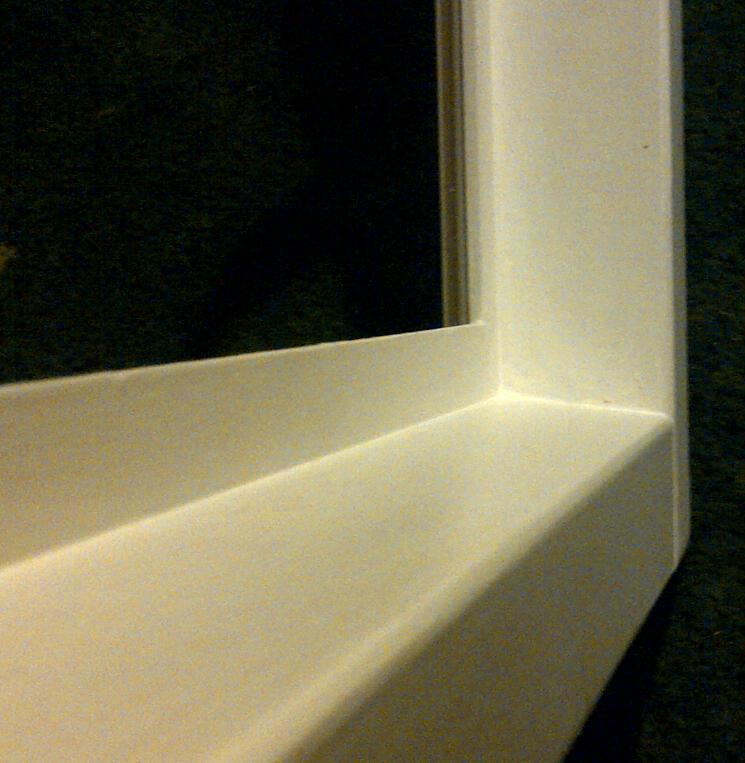

I have to glaze 18 vented and drained timber window casements with external beading. I'm using 24mm DGUs and following the D3 method statement from Hodgson Sealants which uses their Flexistrip glazing tape (thanks to Dibs for suggesting it) as described here:

http://dij.webs.com/The_D3_Glazing_system_aw_Hodgson.pdf

As I'm new to glazing, I have some questions about glazing packers which I believe is a banner term encompassing several sub-types including: setting blocks, location blocks, bridge packers, wedge packers and bead blocks.

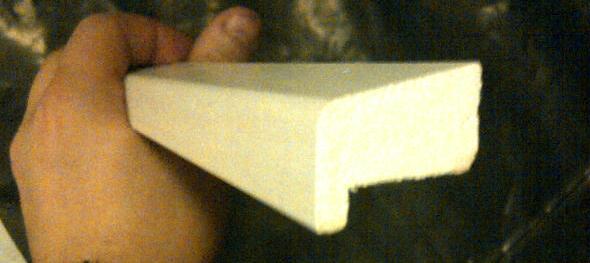

Now, the method statement clearly identifies setting blocks and location blocks. I have read elsewhere that setting blocks are known as bridge packers which incorporate drainage grooves that shed water from the bottom rebate - although all the ones I've observed are always 100mm long and with incremental widths that coincide with DGU sizes eg 24mm, 28mm, 32mm but they appear to have the grooves running in the wrong direction (along their length) unless you're supposed to cut them along their length and place in the rebate with the grooves running perpendicular to the DGU?

However I can't imagine that professional glazers waste their time cutting bridge packers plus why would they have widths that coincide with DGU widths? Please advise.

Next query, the bottom rebates are sloped to shed water, hence using a setting block of constant thickness eg 6mm would not offer support to both panes of the DGU as the top face of the packer would be parallel with the rebate slope. So are setting blocks meant to be wedge shaped? If so then I am struggling to find bridge packers that are also wedge shaped - any suggestions?

Next query, can someone please confirm that location blocks are supposed to be wedged as I believe that is needed to 'lock' the DGU in position (side to side only)?

Next query, the method statement identifies bead packers that are to be used to space the bottom 'hockey stick' bead away from the rebate to enable water to drain away. Now, is a bead packer completely separate to a setting/bridge packer or if I use extra wide setting/bridge packers beneath the DGU can they double up as bead packers? However, I can only find bridge packers in a maximum width of 32mm (ignoring the parallel groove issue) which would only offer ~5mm* of support to the 20mm wide hockey stick bead which IMHO would cause it to twist and/or split when pinned. I can buy 20mm bridge packers which would seem more sensible for the 20mm wide hockey stick bead.

Help me please - I just want to buy and use the correct packers!

Thanks,

Chris

* 5mm = 32mm - 24mm DGU - 2 x 1.5mm of compressed Flexistrip glazing tape.

I have to glaze 18 vented and drained timber window casements with external beading. I'm using 24mm DGUs and following the D3 method statement from Hodgson Sealants which uses their Flexistrip glazing tape (thanks to Dibs for suggesting it) as described here:

http://dij.webs.com/The_D3_Glazing_system_aw_Hodgson.pdf

As I'm new to glazing, I have some questions about glazing packers which I believe is a banner term encompassing several sub-types including: setting blocks, location blocks, bridge packers, wedge packers and bead blocks.

Now, the method statement clearly identifies setting blocks and location blocks. I have read elsewhere that setting blocks are known as bridge packers which incorporate drainage grooves that shed water from the bottom rebate - although all the ones I've observed are always 100mm long and with incremental widths that coincide with DGU sizes eg 24mm, 28mm, 32mm but they appear to have the grooves running in the wrong direction (along their length) unless you're supposed to cut them along their length and place in the rebate with the grooves running perpendicular to the DGU?

However I can't imagine that professional glazers waste their time cutting bridge packers plus why would they have widths that coincide with DGU widths? Please advise.

Next query, the bottom rebates are sloped to shed water, hence using a setting block of constant thickness eg 6mm would not offer support to both panes of the DGU as the top face of the packer would be parallel with the rebate slope. So are setting blocks meant to be wedge shaped? If so then I am struggling to find bridge packers that are also wedge shaped - any suggestions?

Next query, can someone please confirm that location blocks are supposed to be wedged as I believe that is needed to 'lock' the DGU in position (side to side only)?

Next query, the method statement identifies bead packers that are to be used to space the bottom 'hockey stick' bead away from the rebate to enable water to drain away. Now, is a bead packer completely separate to a setting/bridge packer or if I use extra wide setting/bridge packers beneath the DGU can they double up as bead packers? However, I can only find bridge packers in a maximum width of 32mm (ignoring the parallel groove issue) which would only offer ~5mm* of support to the 20mm wide hockey stick bead which IMHO would cause it to twist and/or split when pinned. I can buy 20mm bridge packers which would seem more sensible for the 20mm wide hockey stick bead.

Help me please - I just want to buy and use the correct packers!

Thanks,

Chris

* 5mm = 32mm - 24mm DGU - 2 x 1.5mm of compressed Flexistrip glazing tape.