Doug71

Established Member

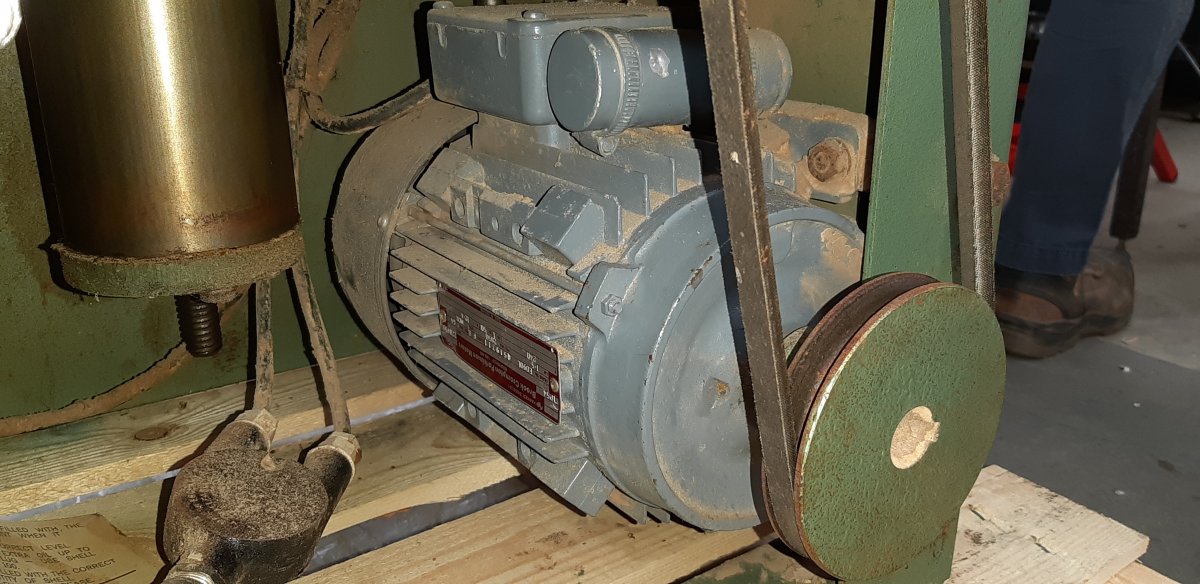

My old Sedgwick MB planer recently started throwing off it's Vee belt, when I checked it had a split in it so I went to get a new one. The chap where I get them from laughed at it and said it was about 40 years old so I presume the original belt. When I was fitting it I noticed that the pulleys are about 12mm out of line, they are parallel just not in line. I can't see that anything has moved and everything looks original, could it have left the factory like this? The person who owned it before me had it about 15 years and he never changed anything but he bought it second hand so don't know it's history before then.

I understand the pulleys should be in line or it can cause damage but as far as I can see it's always being like this. If the bottom pulley did go across 12mm the belt would be almost catching the chain.

Some photos

Only thing I see strange is a second hole drilled in the bar that carries the motor which would move it back but then the other bolts wouldn't line up like the one that moves the motor to tension the belt

Am hoping that @deema picks up on this because I would be interested in if the one he is refurbishing is the same.

Thanks, Doug

I understand the pulleys should be in line or it can cause damage but as far as I can see it's always being like this. If the bottom pulley did go across 12mm the belt would be almost catching the chain.

Some photos

Only thing I see strange is a second hole drilled in the bar that carries the motor which would move it back but then the other bolts wouldn't line up like the one that moves the motor to tension the belt

Am hoping that @deema picks up on this because I would be interested in if the one he is refurbishing is the same.

Thanks, Doug