Kidneycutter

Established Member

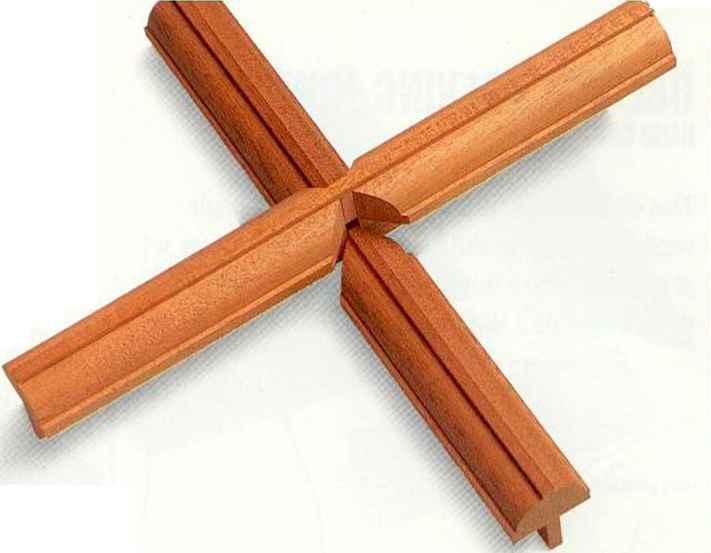

What's the best method to joint the glazing bars?

Thanks for this, new favourite book!If you look at the free on line copy of Riley's Manual of Carpentry and Joinery page 384 shows two methods, one of which is suited to hand work.

The other thing that's puzzling me a s the full length glazing bars. Should these be vertical or horizontal. The one I removed has vertical full bars. However, I'm sure I read somewhere, perhaps goring's book, that it's better to have the horizontal bars full as they hold the weight of the Glass.

Enter your email address to join: