You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

router that you can change blades

- Thread starter woodcarver

- Start date

Help Support UKworkshop.co.uk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

AJB Temple

Finely figured

Wow. are you sure that is for a router? I would be very worried that the blades would come out in use and get me.

Trevanion

Greatest Of All Time

I stopped at £50, it went for over £80 in the end. I kinda liked the novelty of it more than anything and I'd never seen a Whitehill router bit before.

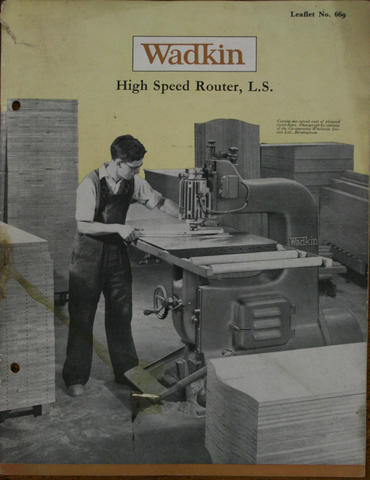

If I had to guess I would say it fitted in an overhead router like the old Wadkin ones.

Generally, you want the rim speed of cutters to stay above 5000ft and below 10000ft per minute otherwise you get into trouble with wood cutting gear. An old-style Whitehill block 5" cutter block spinning at 6000RPM has a rim speed of around 7500ft per minute which means a cutter ejects from the block at around 85MPH give or take. You'd never spin a 2" bit at 30,000RPM as it would just burn and wreck the cutters in double time. I'd probably spin it at 15,000RPM maximum which would also have a rim speed of around 7500ft per minute.

I like the old Whitehill and Wadkin friction blocks, they scare the pants off the uninitiated but they're relatively safe in capable hands. This one below is a very early Whitehill block, it looks a bit rough but mechanically it's perfect and has obviously been looked after for the last 60+ years.

If I had to guess I would say it fitted in an overhead router like the old Wadkin ones.

There must be better ways to die. That type of clamped cutter was banned from spindles thirty years ago and they only spin at 5-10,000RPM

In a router that can go 30,000, I would not want to be anywhere near

Generally, you want the rim speed of cutters to stay above 5000ft and below 10000ft per minute otherwise you get into trouble with wood cutting gear. An old-style Whitehill block 5" cutter block spinning at 6000RPM has a rim speed of around 7500ft per minute which means a cutter ejects from the block at around 85MPH give or take. You'd never spin a 2" bit at 30,000RPM as it would just burn and wreck the cutters in double time. I'd probably spin it at 15,000RPM maximum which would also have a rim speed of around 7500ft per minute.

I like the old Whitehill and Wadkin friction blocks, they scare the pants off the uninitiated but they're relatively safe in capable hands. This one below is a very early Whitehill block, it looks a bit rough but mechanically it's perfect and has obviously been looked after for the last 60+ years.

Last edited:

TheTiddles

Established Member

On my god, not only no but hell no.

When I was a teenager I made a balancing disk for my dad’s lathe with a disk of ply screwed to the back of the chuck to which I attached lumps of tool steel with screws and tape to balance a large burr.

Slow it was ok, fast was also ok till with a bang one piece of steel flew off, at that point the lathe started walking across the floor, some of the other lumps of steel also flew off, one dented the steel garage door, one went through the plasterboard of the wall and another piece is somewhere in the ceiling, eventually it walked far enough that it pulled the plug out the wall and the lathe stopped.

That cutter block in a router would be almost as stupid.

Who on earth paid anything for it, not to mention over £80?!

Aidan

When I was a teenager I made a balancing disk for my dad’s lathe with a disk of ply screwed to the back of the chuck to which I attached lumps of tool steel with screws and tape to balance a large burr.

Slow it was ok, fast was also ok till with a bang one piece of steel flew off, at that point the lathe started walking across the floor, some of the other lumps of steel also flew off, one dented the steel garage door, one went through the plasterboard of the wall and another piece is somewhere in the ceiling, eventually it walked far enough that it pulled the plug out the wall and the lathe stopped.

That cutter block in a router would be almost as stupid.

Who on earth paid anything for it, not to mention over £80?!

Aidan

Inspector

Nyuck, Nyuck, Nyuck!

I don't see it being any different than the big panel raising bits. Slow the speed to 10,000 RPM or so and only in a router table with most buried in the fence, taking progressively deeper cuts. But then I live in the land of dado blades.

Pete

Pete

Trevanion

Greatest Of All Time

That cutter block in a router would be almost as stupid.

You'd never use it free-hand routing because that would be a complete death wish even with a fence. It would work very nicely in a router table at slower speeds and I could see that it would be very handy for replicating really small and detailed profiles basically working as a smaller scale spindle moulder.

Who on earth paid anything for it, not to mention over £80?!

Someone with deeper pockets than myself, evidently!

Similar threads

- Replies

- 0

- Views

- 127

- Replies

- 4

- Views

- 766

- Replies

- 5

- Views

- 288

Latest posts

-

-

making simple unfinished wood picture frames - what set up for a newbie?

- Latest: Trextr7monkey

-

-

-

-

-

-