Hello, I need to round over some 1x2 pine on my first woodworking project and have come to a bit of an impasse. I have a titan 1/2" plunge router and thought it was going to be as simple as just running it down the side of the wood, I am however finding during my practice run that when I get to the end of the workpiece I don't have enough control to keep the router flat and I end up with an inconsistent round over.

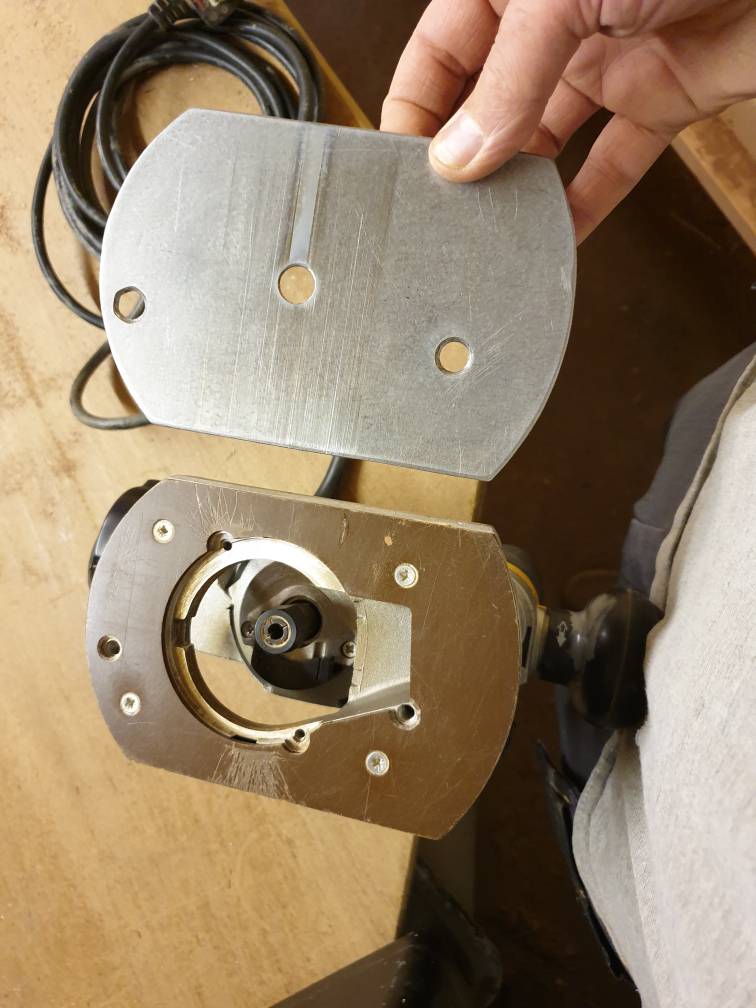

My initial thought was to mount it to a scrap piece of 12mm mdf but I don't think that the titan router has an option to have it run without me holding the switch and I also don't think that I've got sufficient remaining plunge depth to make up for the 12mm of mdf.

Is there a solution that wont involve me buying more equipment?

My initial thought was to mount it to a scrap piece of 12mm mdf but I don't think that the titan router has an option to have it run without me holding the switch and I also don't think that I've got sufficient remaining plunge depth to make up for the 12mm of mdf.

Is there a solution that wont involve me buying more equipment?