sploo

Somewhat extinguished member

Slightly off topic from the original restoration, but it's the first use "in anger" of the mill + DRO...

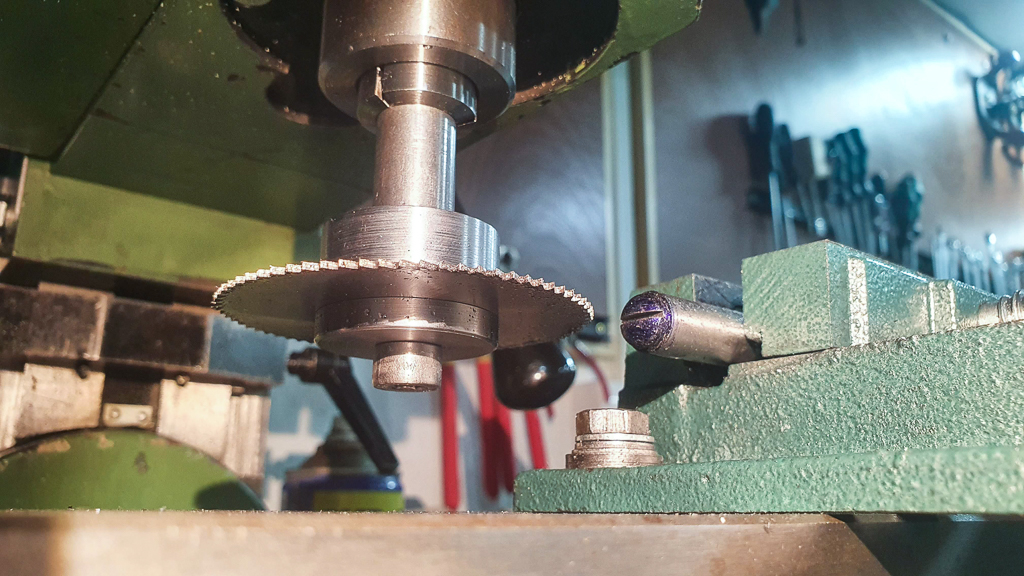

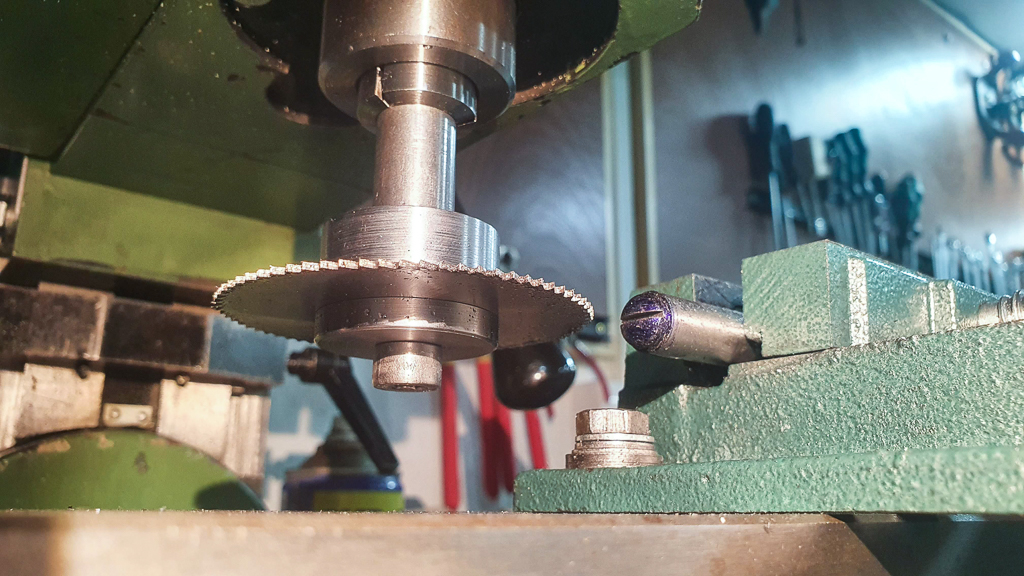

I needed to make a screw for an early Stanley Bedrock 604 1/2 I've been restoring. The screw was turned on the lathe, and mounted in a rod with a tapped hole. The mill came with a selection of slitting saws, but no arbor, so I knocked one up on the lathe and found the blade best suited for the screw head slot.

The DRO made it really easy to touch off on the sides of the screw head to set the centre height, and get the slot depth just right:

Nothing particularly special, but it's the first screw I've made from scratch:

And it even fits:

I needed to make a screw for an early Stanley Bedrock 604 1/2 I've been restoring. The screw was turned on the lathe, and mounted in a rod with a tapped hole. The mill came with a selection of slitting saws, but no arbor, so I knocked one up on the lathe and found the blade best suited for the screw head slot.

The DRO made it really easy to touch off on the sides of the screw head to set the centre height, and get the slot depth just right:

Nothing particularly special, but it's the first screw I've made from scratch:

And it even fits: