Ttrees

Iroko loco!

Sorry been up all night, getting a bit dozy

It just appeared to me in post 12 that you might have had that idea.

I was unaware you had a planer thicknesser and got the impression you might have been doing the rest by hand.

That will certainly speed things up , and make one less concerned about doing a bit of extra planing.

, and make one less concerned about doing a bit of extra planing.

More power to ya!

All the best Bjgodefr

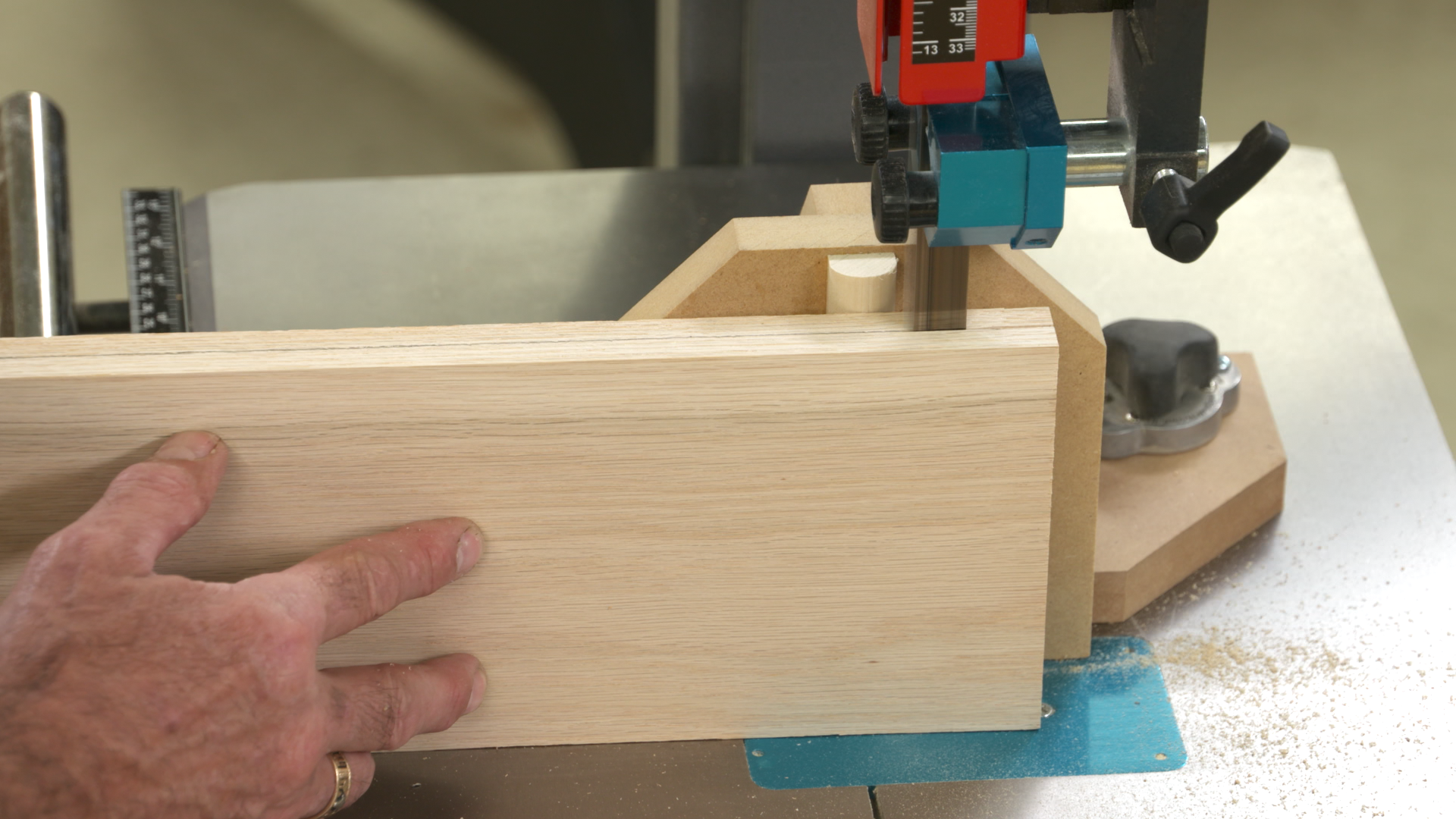

Love to hear others experiences resawing steamed beech

Tom

It just appeared to me in post 12 that you might have had that idea.

I was unaware you had a planer thicknesser and got the impression you might have been doing the rest by hand.

That will certainly speed things up

More power to ya!

All the best Bjgodefr

Love to hear others experiences resawing steamed beech

Tom