Coyote

Established Member

What is it Andy? Some sort of dowel shaper?

It's a multiple size die, to cut small sizes of Whitworth threads in metal.What is it Andy? Some sort of dowel shaper?

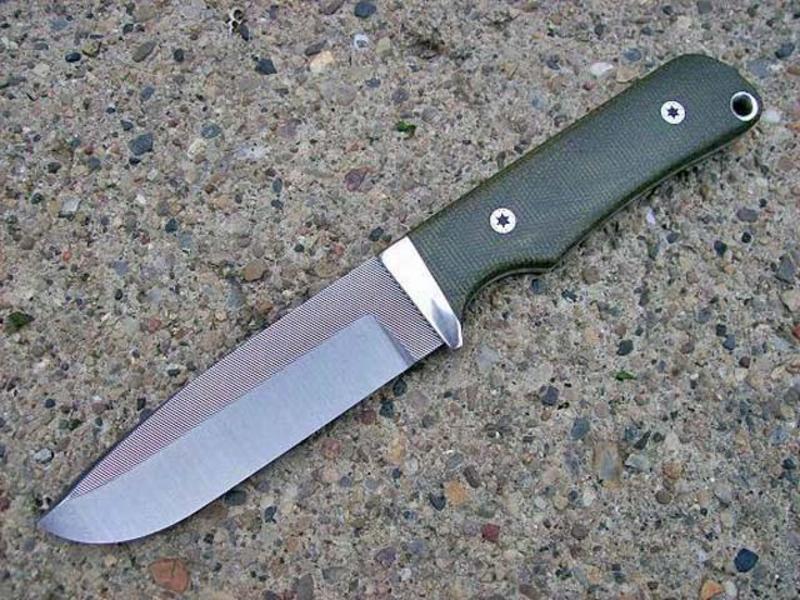

There is a company in the US that uses a very fine abrasive blasting process to sharpen files and rasps. They have been doing it since 1932. I don’t know it’ll there is a British or European company doing the same.

https://boggstool.com/

Pete

As you know everything about everything, in a most certain fashion......

........ MikeG has decreed that, since its on the internet, it must be wrong. Well, unless it's a MikeG pronouncement. .....

including this

Tread carefully Eshmiel, that said MikeG will eventually get bored of being self-righteous and rude to you that he will be forced to put you on his naughty list and click his ignore box. Your comments were quite balanced in my opinion, suggesting there were claims being made but more detail was needed, you were clearly taken out of context to fit the agenda of the response you had. And yes the irony of his own comments are lost in the ether. I see so many new (and old) members who simply give up because of responses like MikeG's. Stick with it, I'm interested in what you have to say.Mr G,

As you know everything about everything, in a most certain fashion, I believe you should publish it all here in a Very Long Thread.........You know, from experience rather than some dismissive prejudice offered in the reedy-voiced tone of an auld schoolmarm.

Tread carefully Eshmiel, that said MikeG will eventually get bored of being self-righteous and rude to you that he will be forced to put you on his naughty list and click his ignore box. Your comments were quite balanced in my opinion, suggesting there were claims being made but more detail was needed, you were clearly taken out of context to fit the agenda of the response you had. And yes the irony of his own comments are lost in the ether. I see so many new (and old) members who simply give up because of responses like MikeG's. Stick with it, I'm interested in what you have to say.

What is it about sharpening that draws out so much ire? No other topic seems to generate such a passionate "debate".

....... Though the number of times I actually need a scraper are very few and far between these days (scraping in new white metal bearings for your Ford 100E crankshaft has gone out of fashion you know......

Enter your email address to join: