mikefab

Established Member

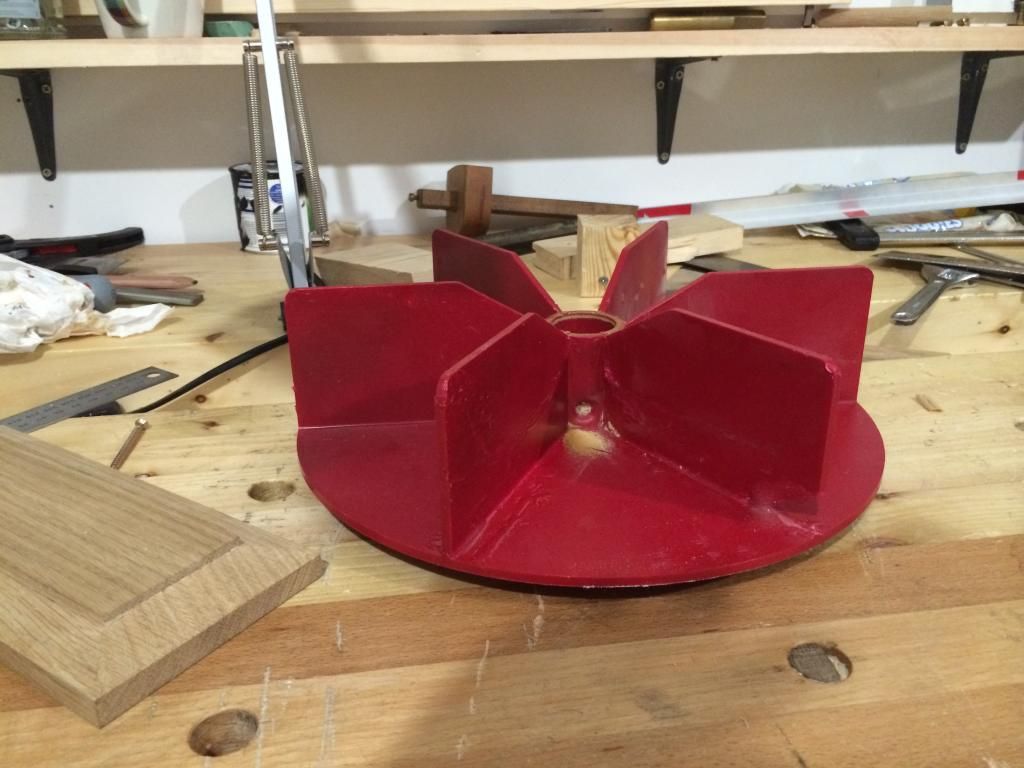

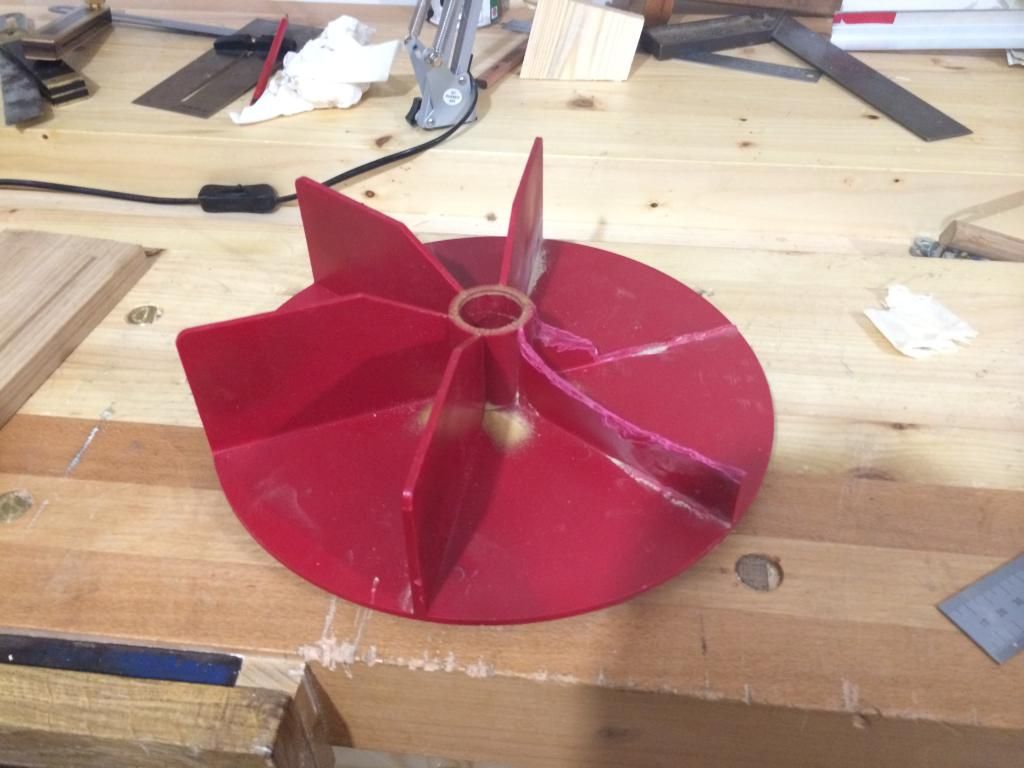

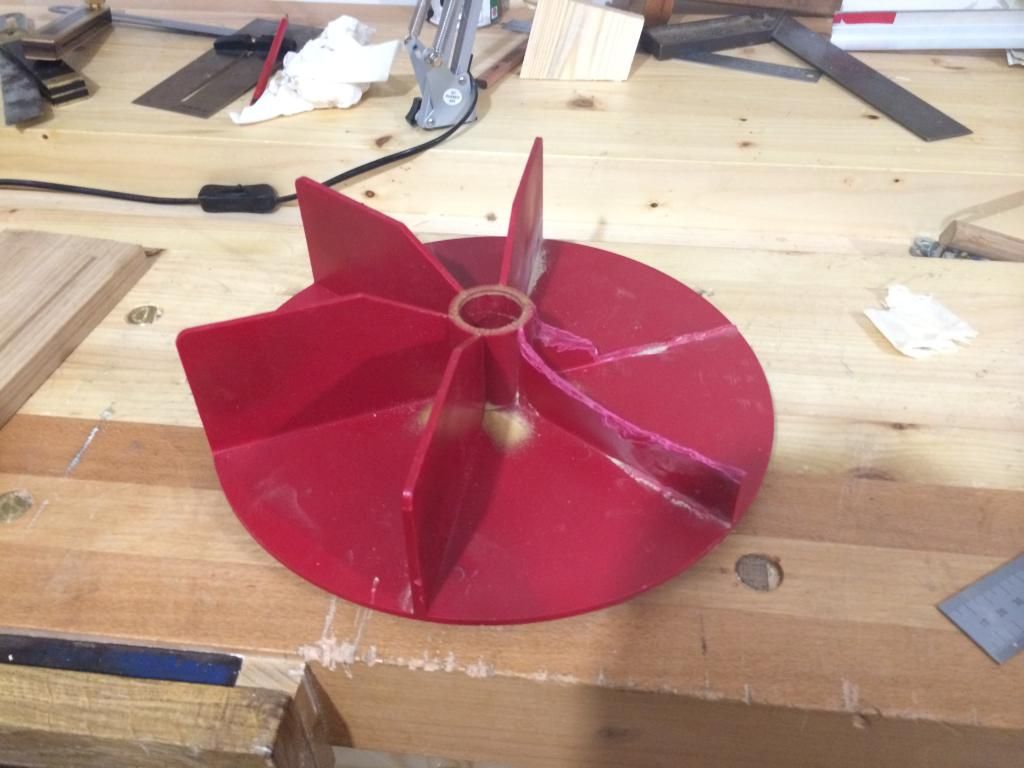

I recently acquired a Kity 694/695 chip extractor to connect to my planer-thicknesser. Unfortunately I was using the extractor to clean up the floor and the workbench when Bang! one of my wooden bench dogs flew up the tube and shattered the impeller. Unfortunately I'd removed the bars guarding the intake as all the chips from the P/T were getting hung up on it and blocking it every 30s....

I have contacted NMA Agencies (the former Kity importer), who tell me that they have no spares available. The Record power spares are apparently unsuitable. Charnwood's steel fans are slightly oversize but might fit (305mm vs 274mm, I need to measure casing when I get home), but the bore is 20 or 21 mm and my motor has a 14mm shaft. I've done Google and Ebay searches for reducing sleeves of that size with no success. I also spoke to Beatson fans and motors (an industrial fan and motor supplier found via google) who can make a replacement impeller for £300 to £400!!

The extractor only cost me £20, but to buy a new equivalent would be £200 or so, so it is worth doing a bit of work to get this going again.

Does anyone have any other ideas about how I might source a replacement impeller? Or does anyone have a dead Kity extractor that they would like to sell the impeller from??!

Thanks for your help.

I have contacted NMA Agencies (the former Kity importer), who tell me that they have no spares available. The Record power spares are apparently unsuitable. Charnwood's steel fans are slightly oversize but might fit (305mm vs 274mm, I need to measure casing when I get home), but the bore is 20 or 21 mm and my motor has a 14mm shaft. I've done Google and Ebay searches for reducing sleeves of that size with no success. I also spoke to Beatson fans and motors (an industrial fan and motor supplier found via google) who can make a replacement impeller for £300 to £400!!

The extractor only cost me £20, but to buy a new equivalent would be £200 or so, so it is worth doing a bit of work to get this going again.

Does anyone have any other ideas about how I might source a replacement impeller? Or does anyone have a dead Kity extractor that they would like to sell the impeller from??!

Thanks for your help.