ScaredyCat

Established Member

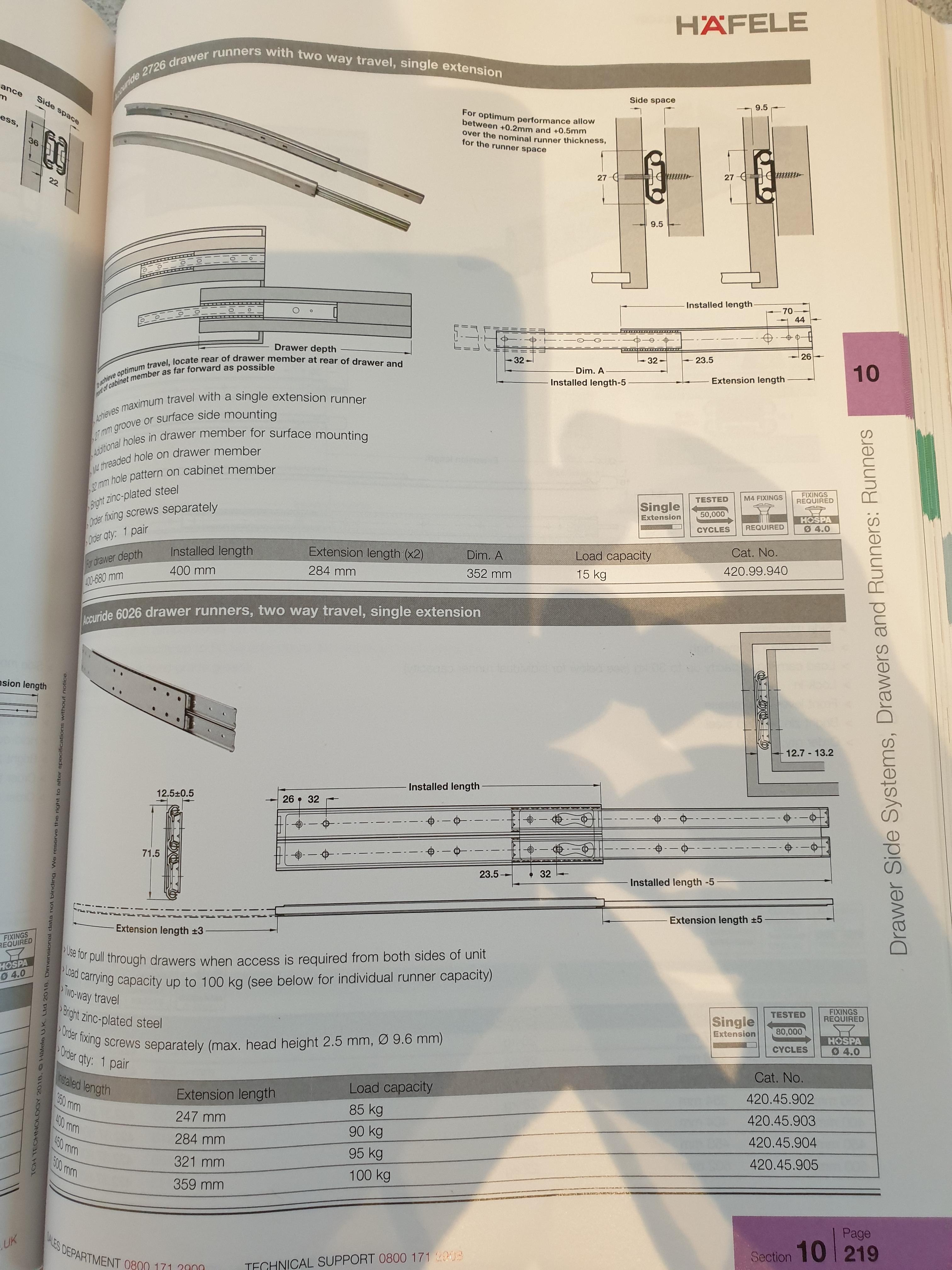

I'm building a mobile island for the kitchen and I want the drawers to be accessible from both sides but I'm struggling to work out how I can hide the hardwood runners/slots for them. Normally they'd be hidden by the drawer front but obviously if they have to be able to slide all the way through that can't be the case.

For one of them, directly under the topn, I was thinking that I'd build 2 boxes, the outer one to hold the drawer and the inner one which is the drawer itself but only 0.5mm smaller? The drawer would be able to open 99% of the way from either side using the side to prevent it tipping.

I'm stuck for the lower drawers because they're reallty sliding shelves with sides and a front but allow taller things to be stored in them.

Anyone got any ideas on this?

.

For one of them, directly under the topn, I was thinking that I'd build 2 boxes, the outer one to hold the drawer and the inner one which is the drawer itself but only 0.5mm smaller? The drawer would be able to open 99% of the way from either side using the side to prevent it tipping.

I'm stuck for the lower drawers because they're reallty sliding shelves with sides and a front but allow taller things to be stored in them.

Anyone got any ideas on this?

.