One of the question I'm asked very often is how I set saws. Funily setting is the first thing people mention when I tell them I make saws.

"Yes, I make saws."

"Really? You have to set the teeth then?"

I do most of my setting with old eclipse 77 or a new Somax for fine teeth. For fine teeth, you can file or grind the hammer part smaller, but that is not the theme of this entry.

The main problem with the somax and the Eclips is the helical anvil. My somax anvil was to soft, too:

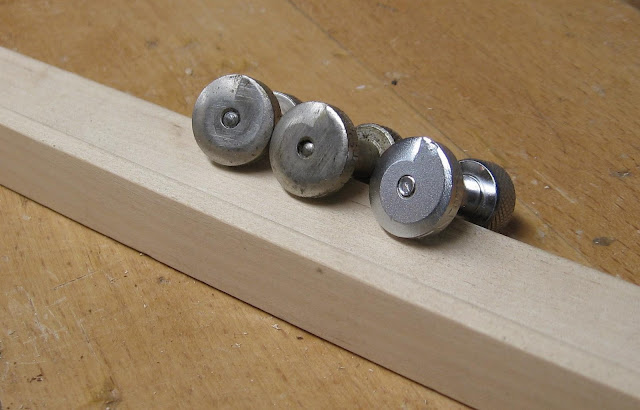

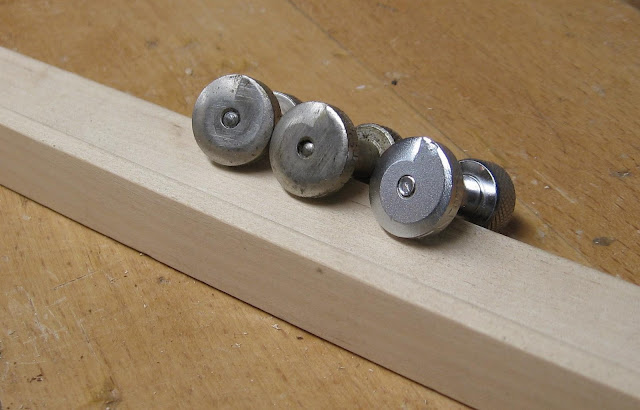

So I asked Gerd Fritsche to make me new anvils of hardened steel:

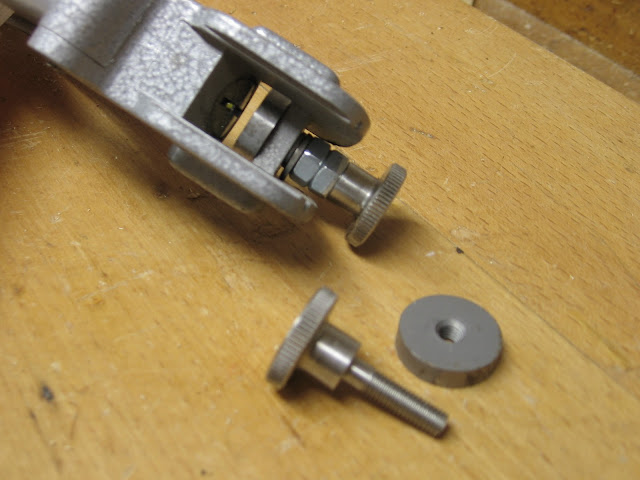

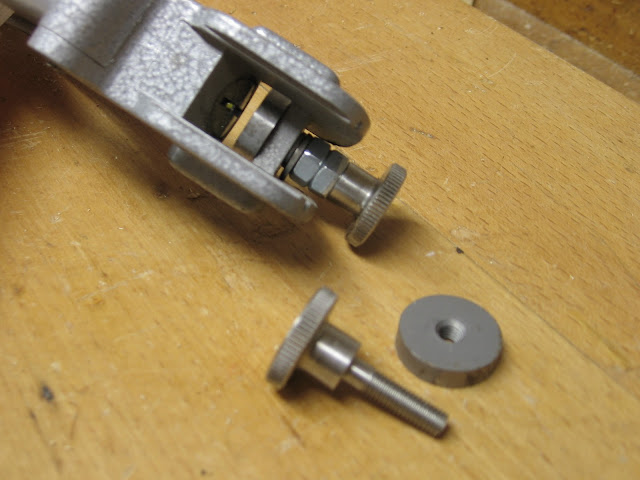

File a little flat is all you need.

Ready to go. Now I can set 0.03mm per side.

Cheers

Pedder

"Yes, I make saws."

"Really? You have to set the teeth then?"

I do most of my setting with old eclipse 77 or a new Somax for fine teeth. For fine teeth, you can file or grind the hammer part smaller, but that is not the theme of this entry.

The main problem with the somax and the Eclips is the helical anvil. My somax anvil was to soft, too:

So I asked Gerd Fritsche to make me new anvils of hardened steel:

File a little flat is all you need.

Ready to go. Now I can set 0.03mm per side.

Cheers

Pedder