robgul

Barry Bucknell is my hero

At the opposite end of the spectrum -today we launched the neighbourhood Tiki Bar I made - ready for alfresco drinks as and when permitted - it's shared by about 10 houses in our road.

It's made from an old bedframe, pallets, a couple of wheels I've had for about 30 years . . . the most sophisticated bit of woodworking is some pocket hole joints to hold the frame together - but hey, it's functional and fun. The name is derived from being in the lower part of the road that includes "Mary" in its name

It's made from an old bedframe, pallets, a couple of wheels I've had for about 30 years . . . the most sophisticated bit of woodworking is some pocket hole joints to hold the frame together - but hey, it's functional and fun. The name is derived from being in the lower part of the road that includes "Mary" in its name

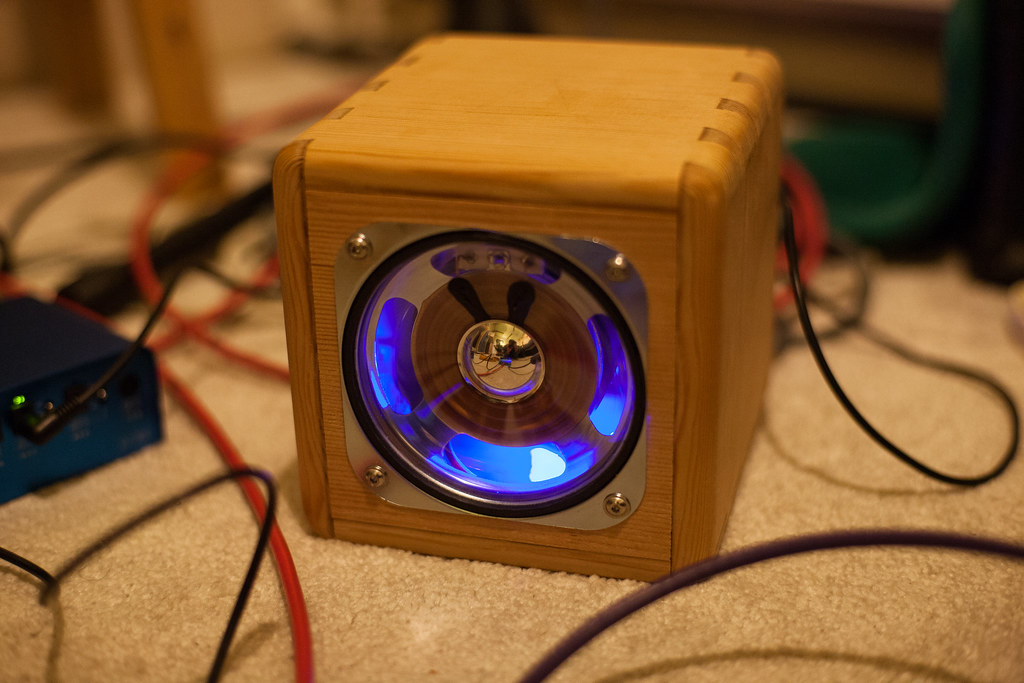

Look in to the cone! the blueberry amp test

Look in to the cone! the blueberry amp test