Bodgers

Established Member

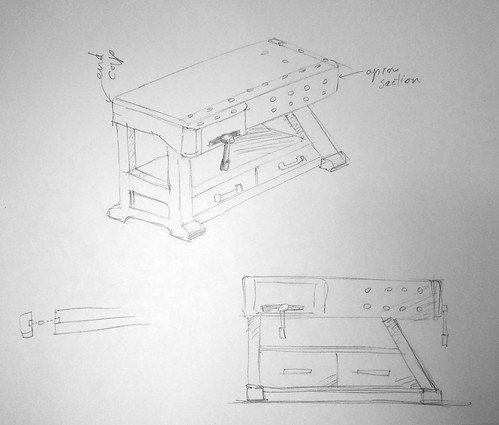

I've been sketching some potential workbench designs for my first 'proper' bench for hand-tool work etc. I like the European workbench design (e.g. ECE and Ulmia benches), but want the front to have a large flat area where long work pieces can be clamped, as per the Roubo style where the legs are flush to the top.

I saw an article in a German magazine called Holzwerken, where they have designed a bench that is basically a European style bench, but with an apron at the front like Paul Seller's or a Nickelson bench. What is interesting about this bench is that they have short-cut the production of the top by using laminated solid beech worktop type blanks.

https://www.youtube.com/watch?v=x1BMQ-1eKfw

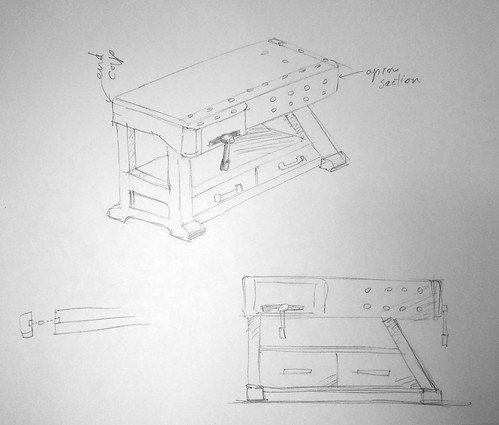

I like this design, but its a bit big for my space, so I sketched out this:

Width is fairly narrow at about 510mm (I might increase this a bit). Length is about 1300mm

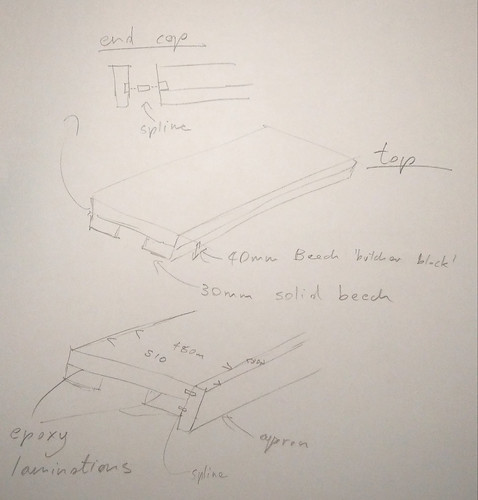

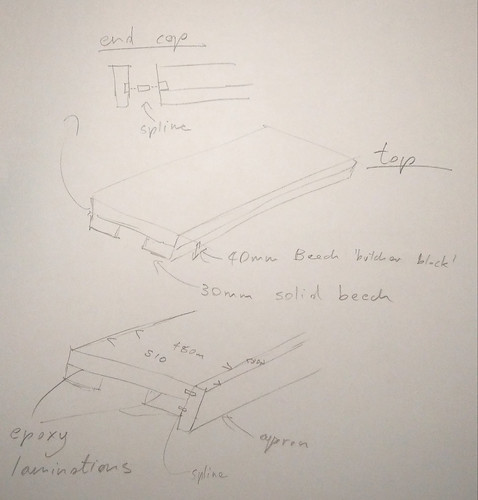

I have a reasonable amount of Beech in the form of thick slabs which will need a fair amount of prep work, so basically the top will be a solid Beech 40mm thick worktop (I have been offered a length on the cheap) and then to the under side of that I will laminate some of my beech in two sections below it. I'll probably use Epoxy to minimise any cupping etc.

I plan on putting end-caps on each side using a spline to act as a kind of bread-board end. This will be bolted in to allow movement. Not sure if that is a good idea...

I am also not sure about the vice. I'm going to buy either the Vertias quick release vice or the Sjobergs adjustable vice and attach the front jaw to it. I would like this to be as high as the apron, but I'm not sure if that would induce a lot of racking top and bottom....

https://www.amazon.com/Sjobergs-SJO-333 ... B00M1MREFO

The design has angled legs on one side, this is purely aesthetic, not sure if its a daft idea. I've seen a bench like this before

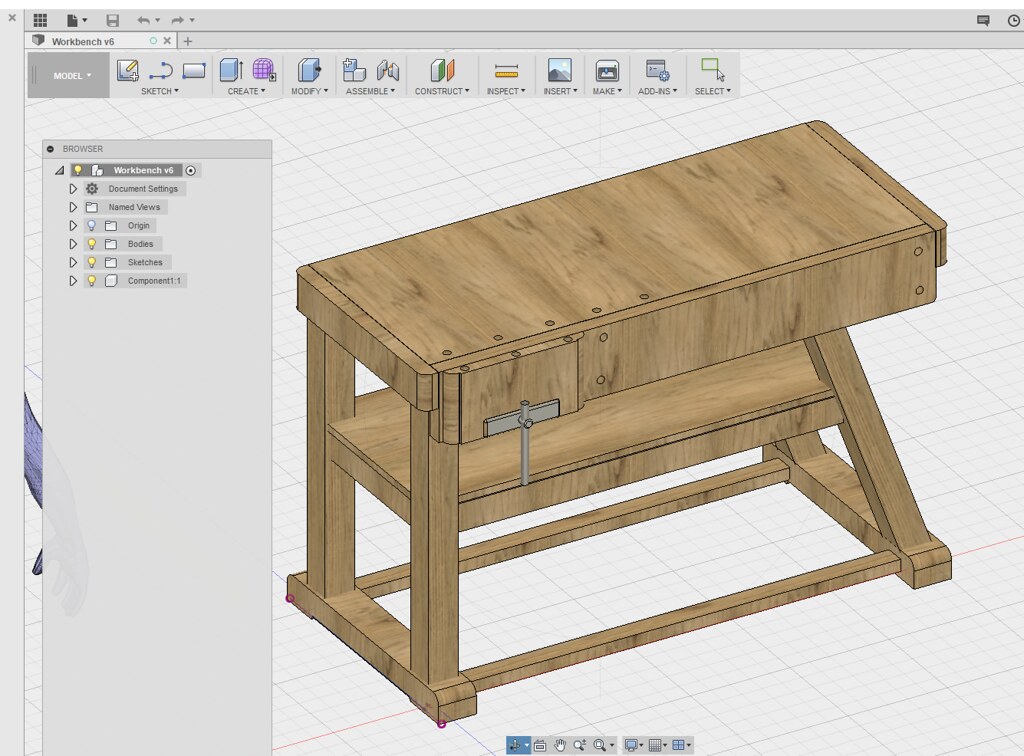

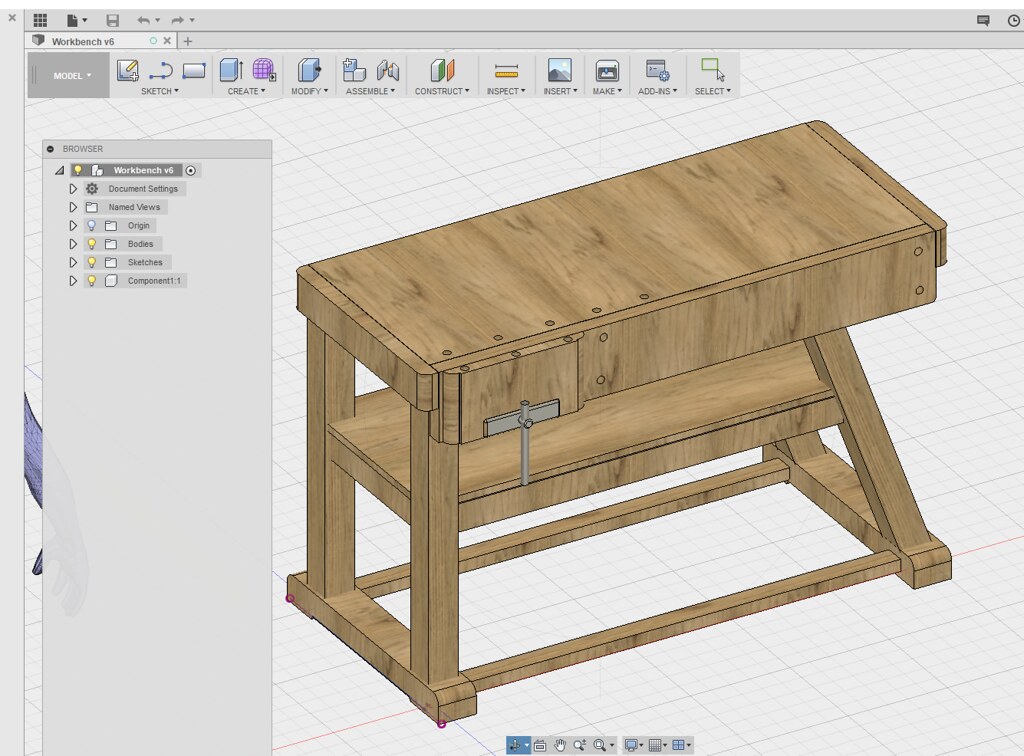

I have sized everything up and produced a model in Fusion 360. Hopefully, this will help with calculating exact sizes etc.

I saw an article in a German magazine called Holzwerken, where they have designed a bench that is basically a European style bench, but with an apron at the front like Paul Seller's or a Nickelson bench. What is interesting about this bench is that they have short-cut the production of the top by using laminated solid beech worktop type blanks.

https://www.youtube.com/watch?v=x1BMQ-1eKfw

I like this design, but its a bit big for my space, so I sketched out this:

Width is fairly narrow at about 510mm (I might increase this a bit). Length is about 1300mm

I have a reasonable amount of Beech in the form of thick slabs which will need a fair amount of prep work, so basically the top will be a solid Beech 40mm thick worktop (I have been offered a length on the cheap) and then to the under side of that I will laminate some of my beech in two sections below it. I'll probably use Epoxy to minimise any cupping etc.

I plan on putting end-caps on each side using a spline to act as a kind of bread-board end. This will be bolted in to allow movement. Not sure if that is a good idea...

I am also not sure about the vice. I'm going to buy either the Vertias quick release vice or the Sjobergs adjustable vice and attach the front jaw to it. I would like this to be as high as the apron, but I'm not sure if that would induce a lot of racking top and bottom....

https://www.amazon.com/Sjobergs-SJO-333 ... B00M1MREFO

The design has angled legs on one side, this is purely aesthetic, not sure if its a daft idea. I've seen a bench like this before

I have sized everything up and produced a model in Fusion 360. Hopefully, this will help with calculating exact sizes etc.