Chunky Monkey

Established Member

Hi all,

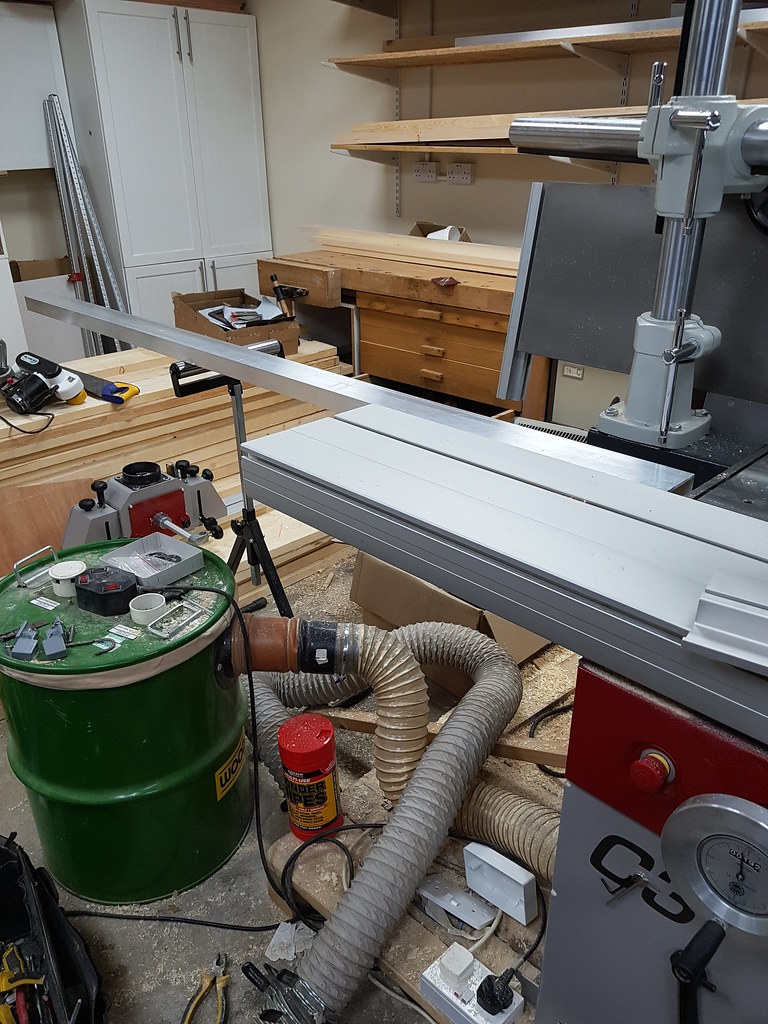

For several years I've owned an Axminster AW106PT2 planer - thicknesser and apart from the niggles with having to reset the outfeed table it's served me well.

Recently though I find myself planing longer and longer boards, today I've machined a couple of 2.4m boards and tomorrow I'm faced with the prospect of planing a couple of 4.2m boards. I'm now finding the short beds, circa 1m, are really making life difficult now, I'm using a roller stand at each end to support the boards but I'm not convinced I can position these accurately enough to ensure the boards remains totally flat on the beds.

I've spent the evening looking at alternative P/Ts, for example the Hammer A3 - 41 has beds that are 1800mm long which would really help, but in every other respect is probably too big a machine for my needs. The A3 - 31 with the bed extensions maybe a better compromise.

Before I go any further down the road of purchasing a new P/T, are there any techniques that help when dealing with long heavy boards, or has anyone had any success with shopmade extension tables?

Thanks

Jon

For several years I've owned an Axminster AW106PT2 planer - thicknesser and apart from the niggles with having to reset the outfeed table it's served me well.

Recently though I find myself planing longer and longer boards, today I've machined a couple of 2.4m boards and tomorrow I'm faced with the prospect of planing a couple of 4.2m boards. I'm now finding the short beds, circa 1m, are really making life difficult now, I'm using a roller stand at each end to support the boards but I'm not convinced I can position these accurately enough to ensure the boards remains totally flat on the beds.

I've spent the evening looking at alternative P/Ts, for example the Hammer A3 - 41 has beds that are 1800mm long which would really help, but in every other respect is probably too big a machine for my needs. The A3 - 31 with the bed extensions maybe a better compromise.

Before I go any further down the road of purchasing a new P/T, are there any techniques that help when dealing with long heavy boards, or has anyone had any success with shopmade extension tables?

Thanks

Jon