cerbarus

Member

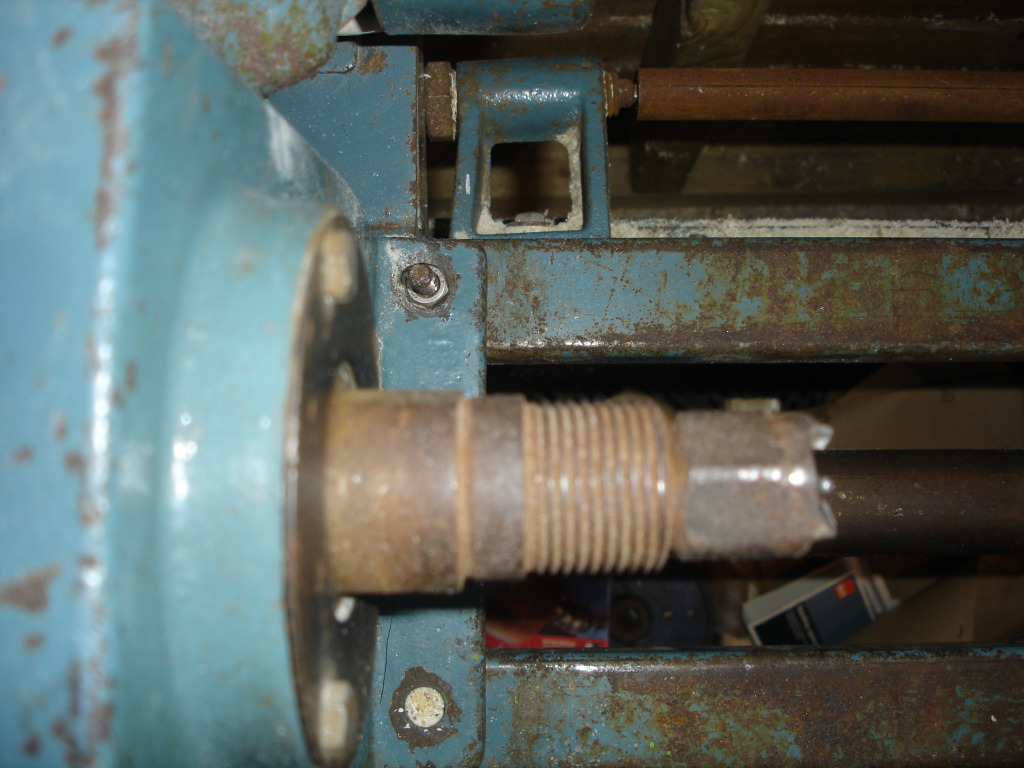

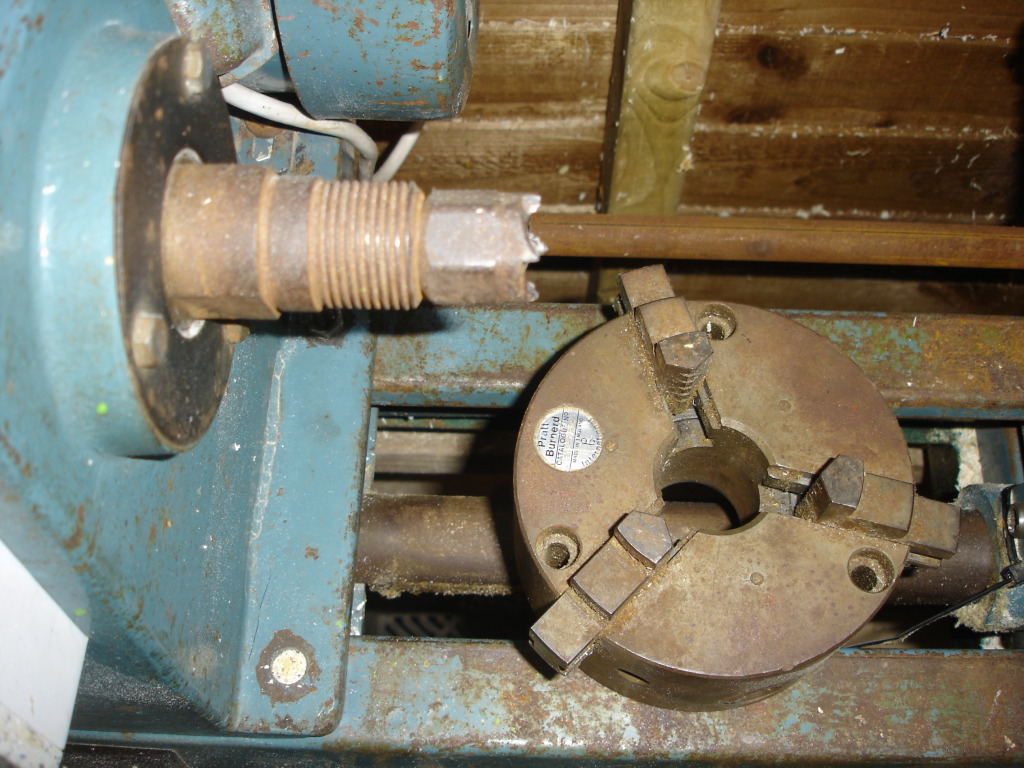

Hi, I wonder if any of you could help me. I have recently been given a Pinnacle NL 1000 wood turning lathe (Belt driven) that has given me great results. However at some point in the past the face plate for attaching the chuck has been lost and i need to find a new one with a centre bore of 28mm. The drive spindle has a central screw attachment for various heads but i am struggling to find a faceplate to screw on the outside. I'm new to wood turning so any advice would be great.

I did try to post this message yesterday but must have made a mistake so if it has already appeared please forgive me.

Thank you

Cerbarus

I did try to post this message yesterday but must have made a mistake so if it has already appeared please forgive me.

Thank you

Cerbarus