banjerbill":hobx5cd7 said:

This is very similar, if not the same, as the Axy hobby bandsaw I have had for years. It was unusable for a long time ( the cut drifted even when freehanding). I fitted a Tuffsaw blade and it transformed it. No problems at all now. Bill

Hello Bill

I believe they are very similar if not one of the same, except the Perform has plastic doors, and the Axminster has steel ones? After an hour or so playing I have to say it's quite an impressive little machine, and for £119.00 a real bargain.

So I pick our lass up from work as usual, home, kettle on, crumpets in the toaster, permission to open the box granted, then off in to the shed I go

I thought I'd get away without cooking tea but it wasn't to be, so play time was cut short :shock:

It didn't start off according to plan, and it's never a good sign when broken pieces of plastic are falling out of the box whilst your trying to remove your pride and joy. There was no damage to the inner or outer box so I can only assume the fan cover which looked as though someone had given it a damn good thrashing, was broken when the saw was packed. A quick to Axminster and a replacement is in the post.

I checked the fan for damage, thankfully all seemed well, and whilst I had the chap from Axminster on the line, I switched the saw on and off. Again, all seemed OK.

I'll start with the bottom guides. Once the table is in place I found it impossible to adjust the bottom roller bearing, there's just no way of getting your hand in with an Allen key. You can see where the grub screw is to the left of the bearing and just above the holding bolt. Loosening this bolt allows the bracket that holds the guides to move in all directions, so once your happy the bracket is in the right position, it's a case of eye balling it for square whilst holding it and re-tightening the bolt (Hope that makes sense)...I used a feeler gauge to set the rear bearing, 1 mm from the back of the blade, and 0.5 mm for the brass side pins.

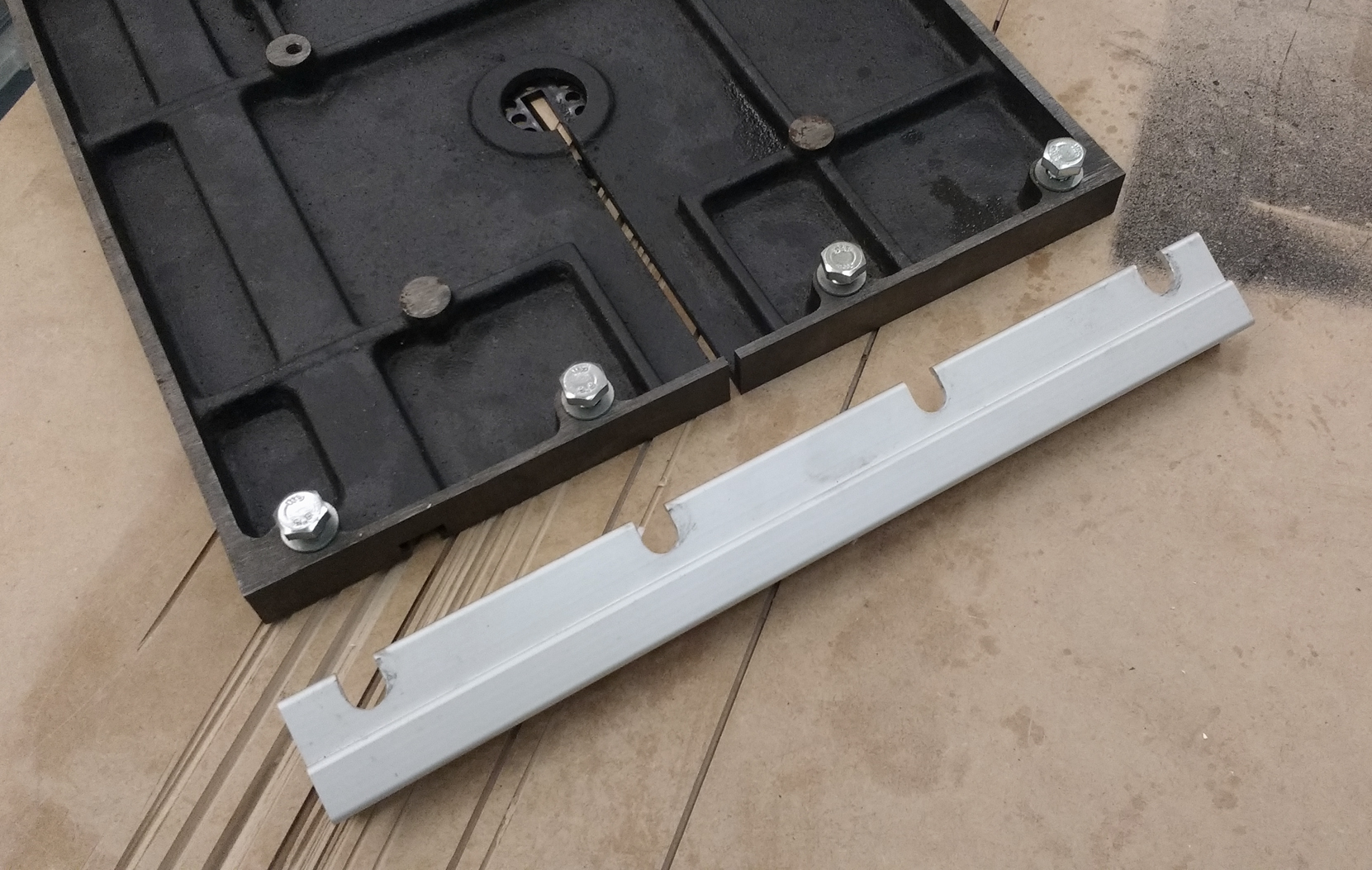

The table. I'm quite impressed with the quality of this, it's looks very well finished and I couldn't find a sharp edge anywhere. The fence rail is held in place with four bolts, I might be tempted to cut this in two so I don't have to remove it when ever I change blades. The plastic insert was level with the surface of the table, and a very snug fit. I don't have a sliding angle gauge so couldn't test the mitre slot but visually, it's looks very clean and free of any poor casting.

Once in place and with it's rear foot, the fence is rock solid and easily removable when not required.

A view general shots.

After finding out the Ferrex BS from Aldi is out of stock, and their customer service unable to say when or if it's coming back, I called Axminster. After a right good chat with one of the chaps I've known for a few years, I decided that whilst the Perform might not have the depth of cut I would have liked, and the motor is a little smaller in comparison to the Ferrex, it could just be the perfect saw

After finding out the Ferrex BS from Aldi is out of stock, and their customer service unable to say when or if it's coming back, I called Axminster. After a right good chat with one of the chaps I've known for a few years, I decided that whilst the Perform might not have the depth of cut I would have liked, and the motor is a little smaller in comparison to the Ferrex, it could just be the perfect saw

Hopefully, I'll only have to wait a couple more hours...More to follow, very soon!

Hopefully, I'll only have to wait a couple more hours...More to follow, very soon!