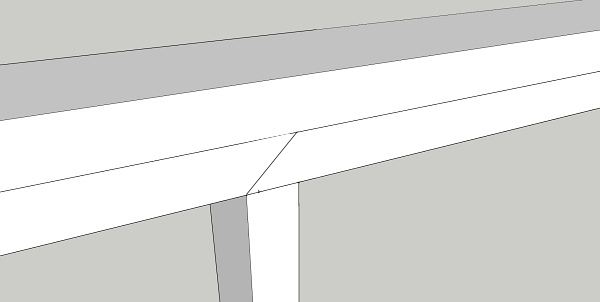

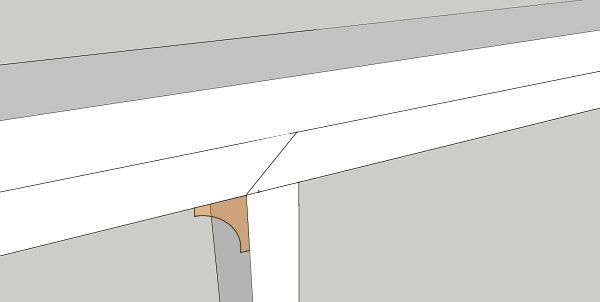

I'm doing a "sun room" using 2x5 oak framing and full length glazed windows. What I'm not sure about is the best way to join two lengths of top plate.

The top plate is doubled up so it is 2x5 and another 2x5. I plan to stagger the join but what join to use? The posts are the same size so there isn't much width to play with.

If I do a half lap should each lap end before the edge of the supporting post?

That post is only 44mm thick.

If I was using blocking then the edges would be screwed or nailed down into that, so could I not just butt join them and fasten with screws/nails?

I would be happy to do m&t but I don't think it would work horizontally.

I'm just not sure the half laps being just 22mm thick is strong enough.

Cheers!

The top plate is doubled up so it is 2x5 and another 2x5. I plan to stagger the join but what join to use? The posts are the same size so there isn't much width to play with.

If I do a half lap should each lap end before the edge of the supporting post?

That post is only 44mm thick.

If I was using blocking then the edges would be screwed or nailed down into that, so could I not just butt join them and fasten with screws/nails?

I would be happy to do m&t but I don't think it would work horizontally.

I'm just not sure the half laps being just 22mm thick is strong enough.

Cheers!