Hi all first the box:

needed somewhere to keep this as it's cardboard packaging was looking a bit shabby. I chose some reclaimed oak (strong) dovetails (strong) rebated base (strong) partly inset lid (strong) - I wanted it strong! it's living in the garage and looking after glass

cut to size with some spares to practice and set up

practiced some dovetails

nice bit of paring - I need the block to keep me level!

dry fit and showing the practice routing done for the base (forgot to photo the base sorry)

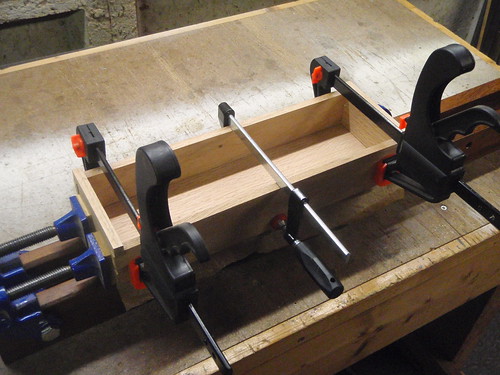

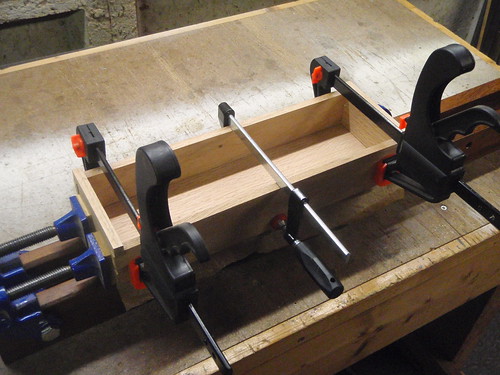

glue up

and cleaned up with lid resting on - quite pleased so far

but ive got a problem - despite many practice attempts fitting butt hinges like this they always go wonky - even with that excellent tutorial in BWW by Mr Lloyd some time ago. And the screws would poke through the lid as it's aonly 8mm thick

thought i might do a hinge with a brass rod in from the side (where the dot is top left in piccy) but would it be strong enough 8mm doesn't seem much to stick into?

feeling a bit stuck and just want to finish it so would welcome any ideas for a swift, simple and strong! lid fixing. I could make another lid if I need to but not another box!! - wish I'd though of this before i'd started!

any thoughts?

cheers - Pete

needed somewhere to keep this as it's cardboard packaging was looking a bit shabby. I chose some reclaimed oak (strong) dovetails (strong) rebated base (strong) partly inset lid (strong) - I wanted it strong! it's living in the garage and looking after glass

cut to size with some spares to practice and set up

practiced some dovetails

nice bit of paring - I need the block to keep me level!

dry fit and showing the practice routing done for the base (forgot to photo the base sorry)

glue up

and cleaned up with lid resting on - quite pleased so far

but ive got a problem - despite many practice attempts fitting butt hinges like this they always go wonky - even with that excellent tutorial in BWW by Mr Lloyd some time ago. And the screws would poke through the lid as it's aonly 8mm thick

thought i might do a hinge with a brass rod in from the side (where the dot is top left in piccy) but would it be strong enough 8mm doesn't seem much to stick into?

feeling a bit stuck and just want to finish it so would welcome any ideas for a swift, simple and strong! lid fixing. I could make another lid if I need to but not another box!! - wish I'd though of this before i'd started!

any thoughts?

cheers - Pete