Was going to make a router fence but decided to do something more interesting instead - making a NVR switch

Having used the saw a bit the one thing that was bothering me was not being able to get to the off button when cutting sheet material. One of the metalworking machines we used to have in the business had a kick bar kill switch so you could stop it without having to go looking for the switch. I always thought that was a good idea so set about recreating it.

The other thing putting me off just buying a NVR switch was their habit of going wrong and the fact that they are a bit cheap and nasty internally.

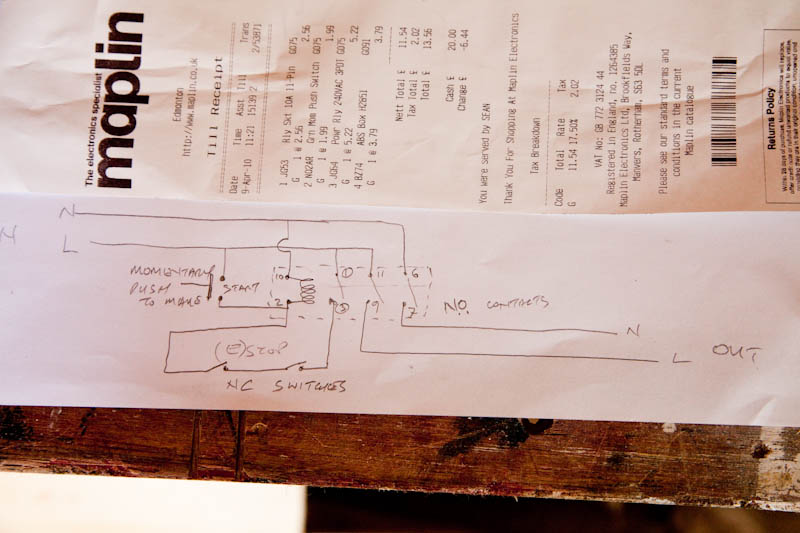

So I went to Maplin and bought some bits. A 3 pole 240v relay (L,N and stop circuit), mounting base, press to make green push button and an enclosure.

here is the receipt for part numbers and prices and my circuit diagram -

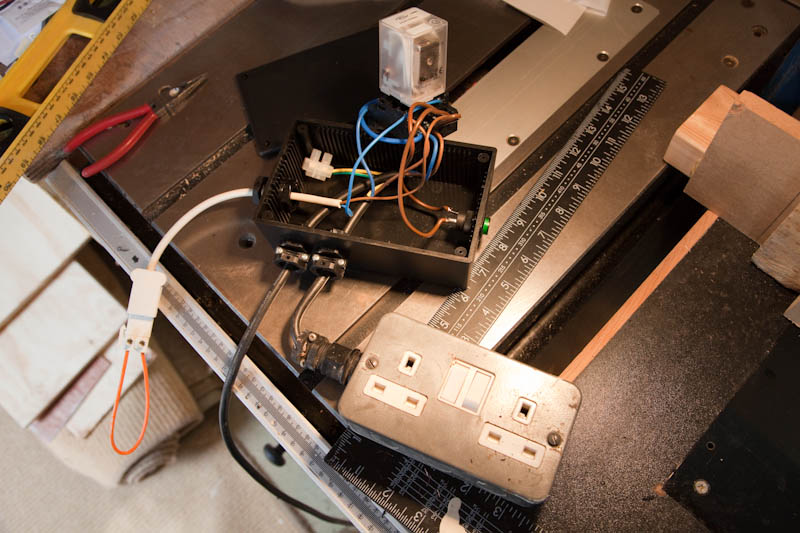

I already had some cable grip bushes and an old metalclad 13A socket. The white lead is the stop circuit. Shorted with a wire just for testing - it works

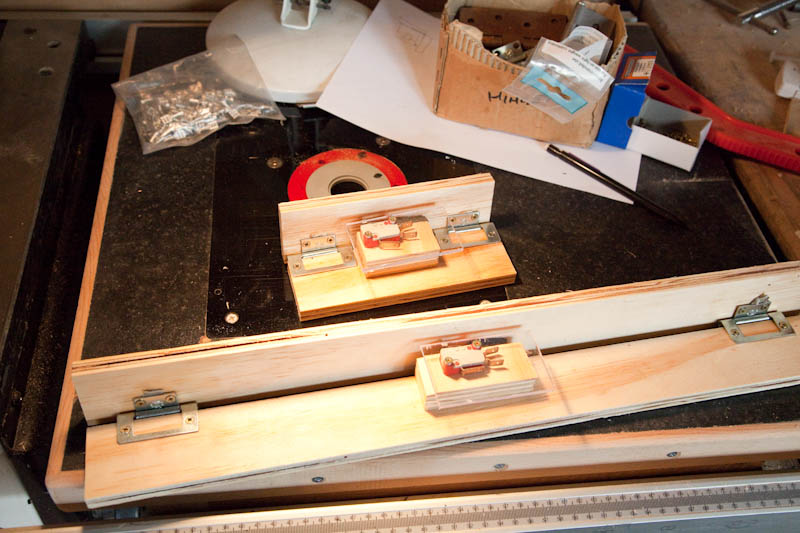

So now i needed some stop switches. strips of ply with hinges and NC contacts used on microswitches which again I already had. Clear Polcarbonate covers to protect the terminals.

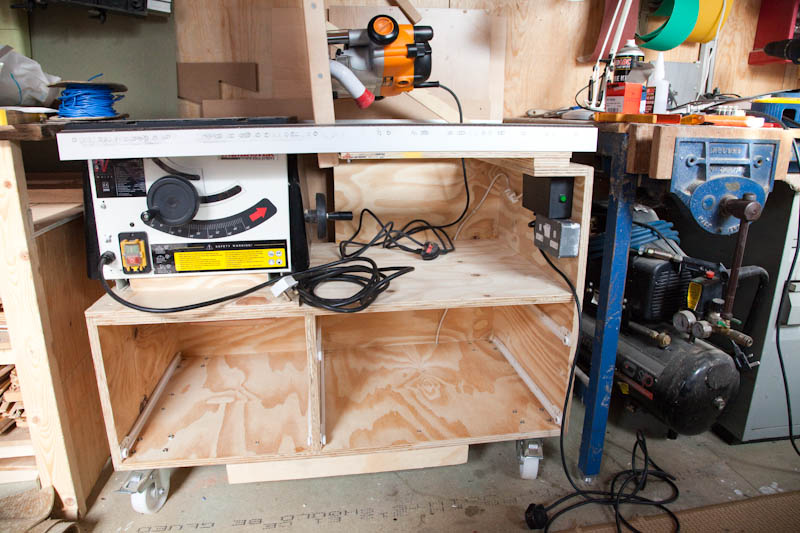

Was a bit awkward but installed under the saw bench and wiring clipped up out of harms way. Cables are gripped near the switches and insulated boots used on the spade terminals.

Heres a view with the router table hinged up to let some light in. drawers are removed.

And with the drawers back in place. Drawers are a bit heavy duty but I didn't want to buy more material just for them.

So I can plug the router in and just press the green button to start it then kick the 'foot switch' to stop it Or I can plug the saw in and use my NVR as an interrupt to stop the saw easily. Press the green button on my NVR, press the start button on the saw and it runs. Kick the stop bar to stop the saw and I'm back to 2 button presses to start the saw. If access to the saws stop button is easy then I can just use that as normal and my NVR stays on.