Did I get it in in time?

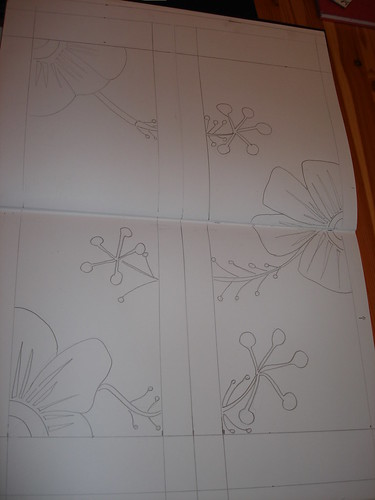

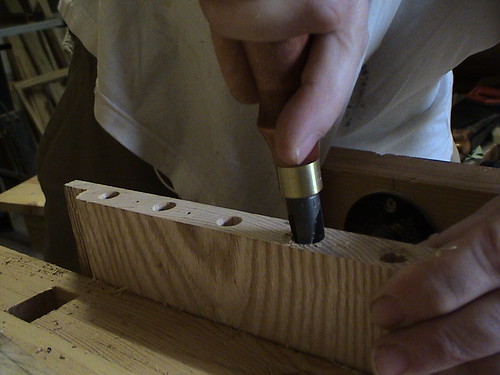

Anyway, the plan was to dowel the cabinet together so that the top and base would overhang the sides and I could put some sort of relief onto the overhang. So I knocked up this quick dowel jig. unfortunately the jig wasn't accurate enough and the dowels ended up out of alignment. All of which is irrelevant as I managed to blow the side out when hammering one of the dowels in so I'm now paused and wondering how to recover.

The dowel jig setup for use.

drilled and countersunk (spot the misalignment)

knocking the dowels in using the jig as a depth gauge.

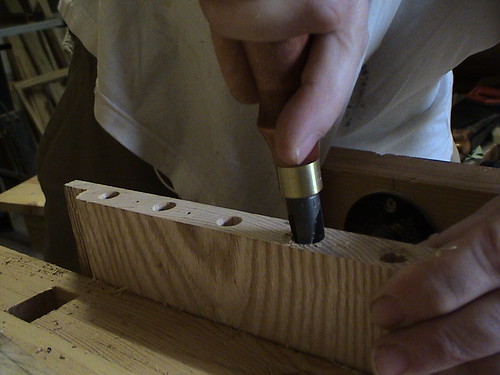

shortly before it all went wrong.

So back to the drawing board, probably have to remake these panels unles I can think of an alternate means of construction.

Mike

Anyway, the plan was to dowel the cabinet together so that the top and base would overhang the sides and I could put some sort of relief onto the overhang. So I knocked up this quick dowel jig. unfortunately the jig wasn't accurate enough and the dowels ended up out of alignment. All of which is irrelevant as I managed to blow the side out when hammering one of the dowels in so I'm now paused and wondering how to recover.

The dowel jig setup for use.

drilled and countersunk (spot the misalignment)

knocking the dowels in using the jig as a depth gauge.

shortly before it all went wrong.

So back to the drawing board, probably have to remake these panels unles I can think of an alternate means of construction.

Mike