Roxie

Established Member

Greetings to you all

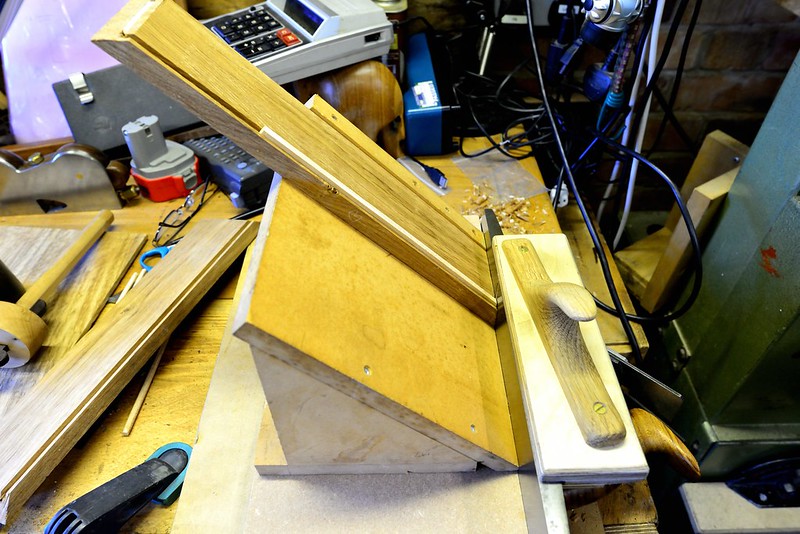

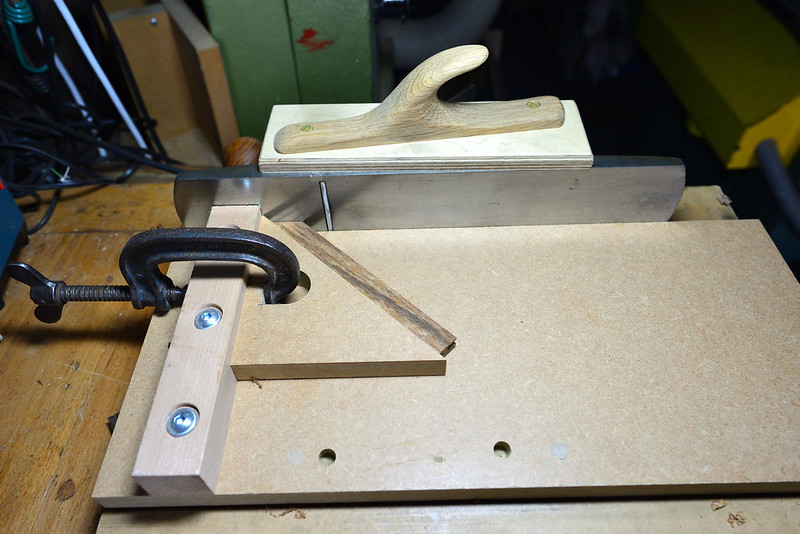

I am about to make a jewellery box with mitred corners. My problem is that height of the box is 6" and my mitre guillotine's capacity is only 4". I do not have a table saw, but do have a router table and planer/thicknesser.

My question is; do I buy a 45deg. chamfer router bit or set my planer to 45deg?

Thank you for your replies (should I get any!!)

John

I am about to make a jewellery box with mitred corners. My problem is that height of the box is 6" and my mitre guillotine's capacity is only 4". I do not have a table saw, but do have a router table and planer/thicknesser.

My question is; do I buy a 45deg. chamfer router bit or set my planer to 45deg?

Thank you for your replies (should I get any!!)

John