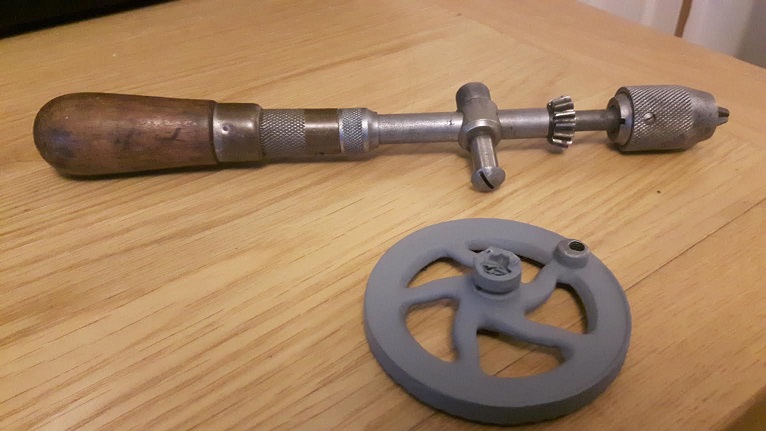

I recently acquired a Millers Falls 3 drill from a very nice, helpful and generous member of UKW. (Thanks again fella if you're reading. :wink: ) I like to peruse the older threads on handtools on here for the wealth of information and I'd seen Millers Falls drills again and again and lots of love for them. So when one came up I decided to see what the fuss was about despite it missing a few bits. Minor things. Like a chuck and a handle. I'll put it on the lookout list I thought. Long story short after a major bit of luck on my part and generosity on the sellers he found a chuck and chucked it in.

So into the rust bucket it all went save the brass and wood handle of course. (A trial run for me of Shield Technology Restore Rust Remover from Mathew at WSH. I love this stuff btw. Bit pricey to be sure but so neutral it's a joy to use.) I was a bit undecided on the extent of the restoration. I don't want a new tool look. But the rust had to go and in the course of it I had to look at the red paint on the wheel. Faded and half gone there was a moment of decision so the brass drill brushes came out. In for a penny.

Strangely for me I didn't take any before photos.

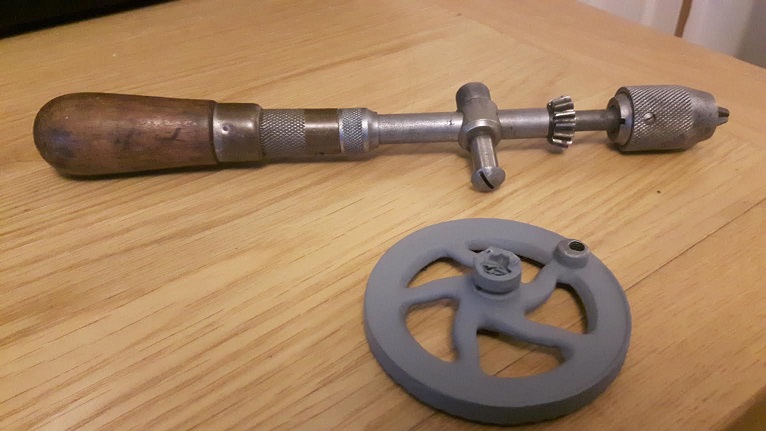

Anyway here it is, with most of the pre 'work' done. The wheel has been acid etched and primed but is taped up so it will clean up better than it looks with any luck.

So. Finally I get round to it. I'm wondering does anyone have either a source for buying the winding arm/parts? I've had a look on the web but nothing jumps out. Then I started wondering. I could make one from some brass.... Might look nice Sooooo....

Does anyone have the offset arm they could measure so I could try and replicate it or does anyone know where I might find the dimensions?

http://hyperkitten.com/pics/tools/fs/ar ... 10/d4.html

(with respect to HyperKitten I hope he doesn't mind me borrowing his photos)

Anyway, thanks for looking.

Cheers

Chris

So into the rust bucket it all went save the brass and wood handle of course. (A trial run for me of Shield Technology Restore Rust Remover from Mathew at WSH. I love this stuff btw. Bit pricey to be sure but so neutral it's a joy to use.) I was a bit undecided on the extent of the restoration. I don't want a new tool look. But the rust had to go and in the course of it I had to look at the red paint on the wheel. Faded and half gone there was a moment of decision so the brass drill brushes came out. In for a penny.

Strangely for me I didn't take any before photos.

Anyway here it is, with most of the pre 'work' done. The wheel has been acid etched and primed but is taped up so it will clean up better than it looks with any luck.

So. Finally I get round to it. I'm wondering does anyone have either a source for buying the winding arm/parts? I've had a look on the web but nothing jumps out. Then I started wondering. I could make one from some brass.... Might look nice Sooooo....

Does anyone have the offset arm they could measure so I could try and replicate it or does anyone know where I might find the dimensions?

http://hyperkitten.com/pics/tools/fs/ar ... 10/d4.html

(with respect to HyperKitten I hope he doesn't mind me borrowing his photos)

Anyway, thanks for looking.

Cheers

Chris