I wish I had seen Dennis's workbench, with the router table, before I went down the path I chose. I suppose timing is everything, but I'm happy with what I have now.

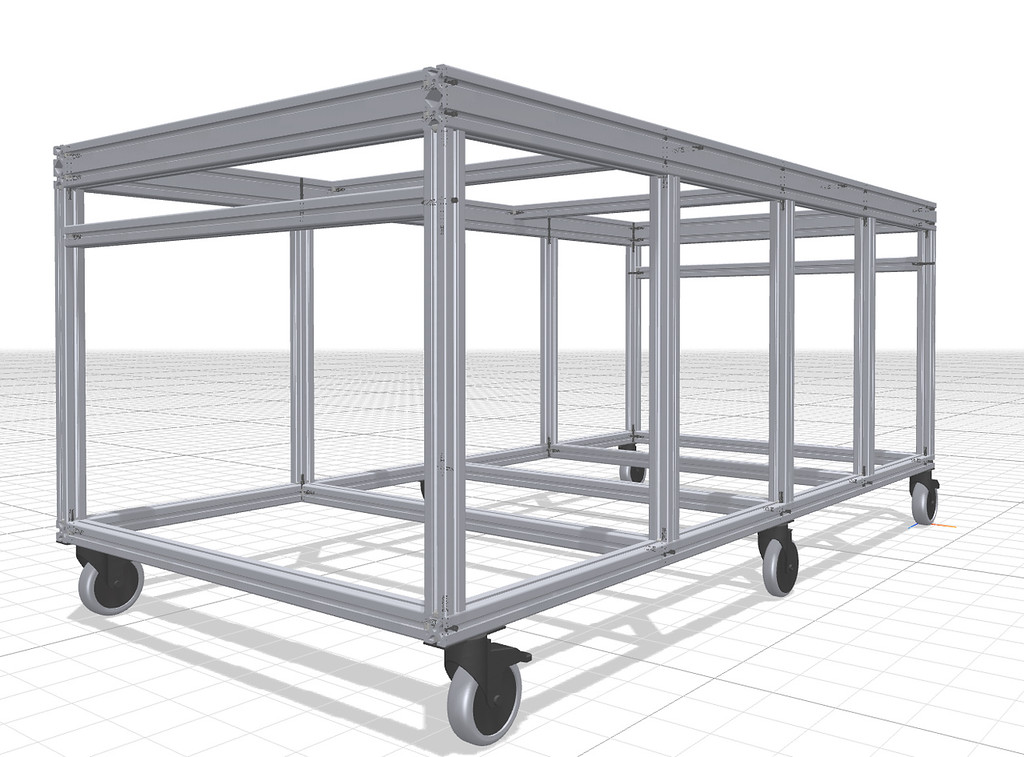

I assembled my new workbench this evening to test fit all of the pieces and double check my measurements for the internal plywood panels and drawers. From start to finish, it took me about an hour and a half to complete the assembly. Nothing is torqued to specs, but it is a stable rolling platform.

I have to take some of it apart to fit in the divider panels and make some relief cuts in the extrusion for the Festool clamps, but it's a good thing I assembled it first. I was off by 20mm in three places for my internal plywood layout because I didn't account for the center offset of the 40x40mm extrusion.

I assembled my new workbench this evening to test fit all of the pieces and double check my measurements for the internal plywood panels and drawers. From start to finish, it took me about an hour and a half to complete the assembly. Nothing is torqued to specs, but it is a stable rolling platform.

I have to take some of it apart to fit in the divider panels and make some relief cuts in the extrusion for the Festool clamps, but it's a good thing I assembled it first. I was off by 20mm in three places for my internal plywood layout because I didn't account for the center offset of the 40x40mm extrusion.