Please give me your opinions on my options for a new desk top.

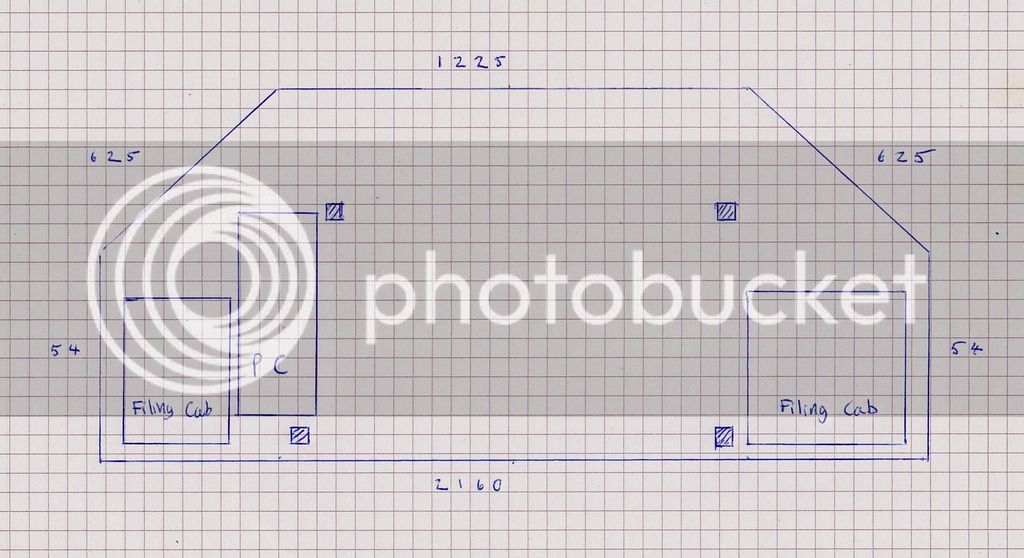

I'm making a desk to fit in a small bay window. The bay has 5 sides, shaped like 5 sides of an octagon, so the desk will be like a rectangle with 2 corners cut off.

The bay is 2m between the window sills. I'd like the desktop to sit on top of the sills, so it will be 2.16m wide, and between 83cm and 93cm deep.

Underneath there will be a filing cabinet either side, which I intend to use for support. The gap between the filing cabinets will be 1.33m. That's a lot, and depending on the material used for the desk, I was thinking of using 2 (or more) lengths of 25 X 25mm (1.2mm ) Steel Square Tube as support.

Options for desk top:

1) Wood kitchen worktop, like oak or beech. This is sold in 2m, 2.4m and 3m lengths, 40mm thick, and up to 96cm width. At 40mm thick I assume it won't flex much, but it will be heavy and still need some support. The actual top should look fine, although not quite as nice as the other options.

2) 3/4" hardwood ply. This would be cheaper and probably need more support. The main negative with this option would be that I'll probably need to add an edge to the front, which won't look as nice as the alternatives.

3) Make a desk top out of old 22mm oak floorboards I have. I would trim these on all four sides and glue them together, presumably on to a piece of 12mm ply. I know that the oak can move a fair bit due to moisture (that's why I have it, it used to be on a floor, before it expanded), and that's probably my main concern, although over a width of 90cm I guess it shouldn't move too much. I don't know if the gluing the boards to the ply (effectively making an engineered board) would restrict the oak too much and lead to cracks etc and if I'd be better not using ply with the floorboards, and just let the oak move a little over the metal supports.

Many thanks

I'm making a desk to fit in a small bay window. The bay has 5 sides, shaped like 5 sides of an octagon, so the desk will be like a rectangle with 2 corners cut off.

The bay is 2m between the window sills. I'd like the desktop to sit on top of the sills, so it will be 2.16m wide, and between 83cm and 93cm deep.

Underneath there will be a filing cabinet either side, which I intend to use for support. The gap between the filing cabinets will be 1.33m. That's a lot, and depending on the material used for the desk, I was thinking of using 2 (or more) lengths of 25 X 25mm (1.2mm ) Steel Square Tube as support.

Options for desk top:

1) Wood kitchen worktop, like oak or beech. This is sold in 2m, 2.4m and 3m lengths, 40mm thick, and up to 96cm width. At 40mm thick I assume it won't flex much, but it will be heavy and still need some support. The actual top should look fine, although not quite as nice as the other options.

2) 3/4" hardwood ply. This would be cheaper and probably need more support. The main negative with this option would be that I'll probably need to add an edge to the front, which won't look as nice as the alternatives.

3) Make a desk top out of old 22mm oak floorboards I have. I would trim these on all four sides and glue them together, presumably on to a piece of 12mm ply. I know that the oak can move a fair bit due to moisture (that's why I have it, it used to be on a floor, before it expanded), and that's probably my main concern, although over a width of 90cm I guess it shouldn't move too much. I don't know if the gluing the boards to the ply (effectively making an engineered board) would restrict the oak too much and lead to cracks etc and if I'd be better not using ply with the floorboards, and just let the oak move a little over the metal supports.

Many thanks