MikeG.

Established Member

Jacob":2gu6tvur said:transatlantic":2gu6tvur said:......It's more of a fine point than a cone anyway.

And if it isn't, file it.

Jacob":2gu6tvur said:transatlantic":2gu6tvur said:......It's more of a fine point than a cone anyway.

I have a woodcraft wheel gauge I picked up from the US last year. Mine can be held flush against the workpiece without it being angled back by the wheel. I use it in preference to my Irwin pin gauge now.MikeG.":2gbrn5ye said:Well remembered, custard. Yep, it's an expensive thing (and otherwise very well engineered) from Workshop Heaven, but the wheel sticks out 2 or 3mm from the shaft (it isn't in front of me, so I'm guessing). This means the shaft can't be used as a reference, which is pivotal to the proper use of a marking gauge. I have no issues using a pin gauge to mark around corners. However, the wheel gauge does something a pin gauge can't: quickly take an absolute measurement of the thickness of a board, which is of course useful when setting out the cutting depths for tails and pins, and for finger joints (box joints).

Edit:

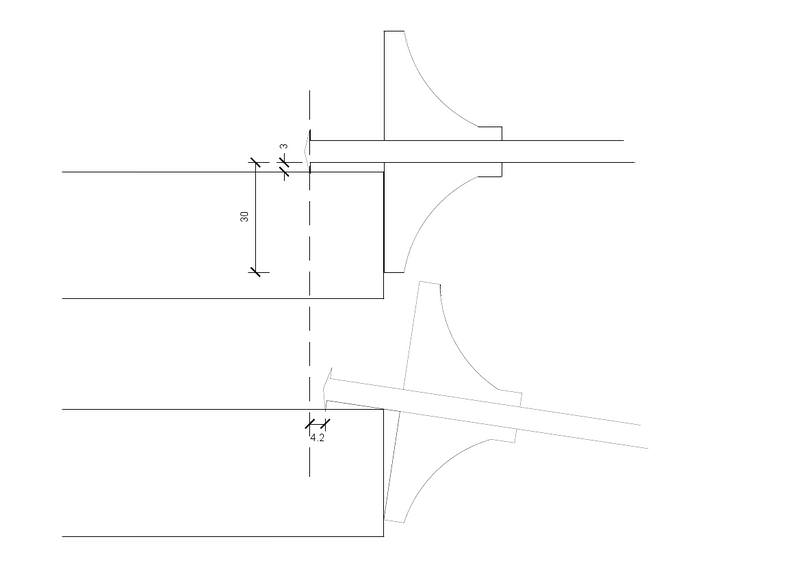

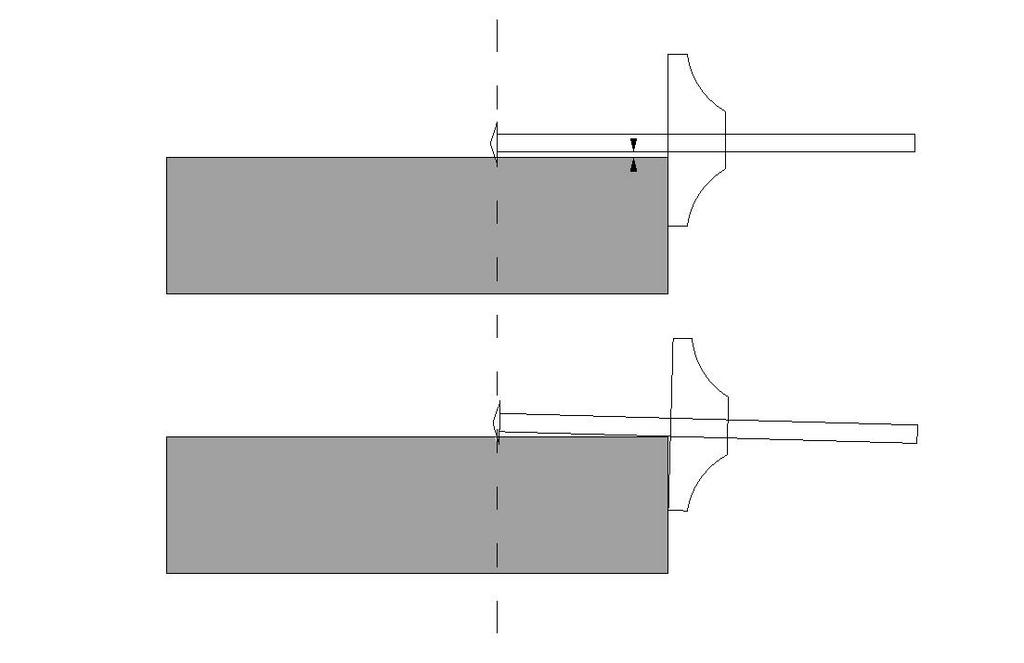

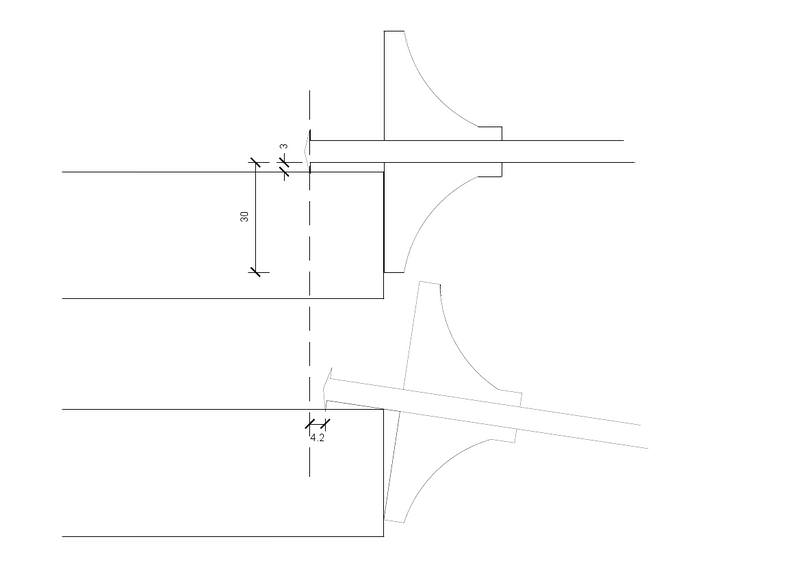

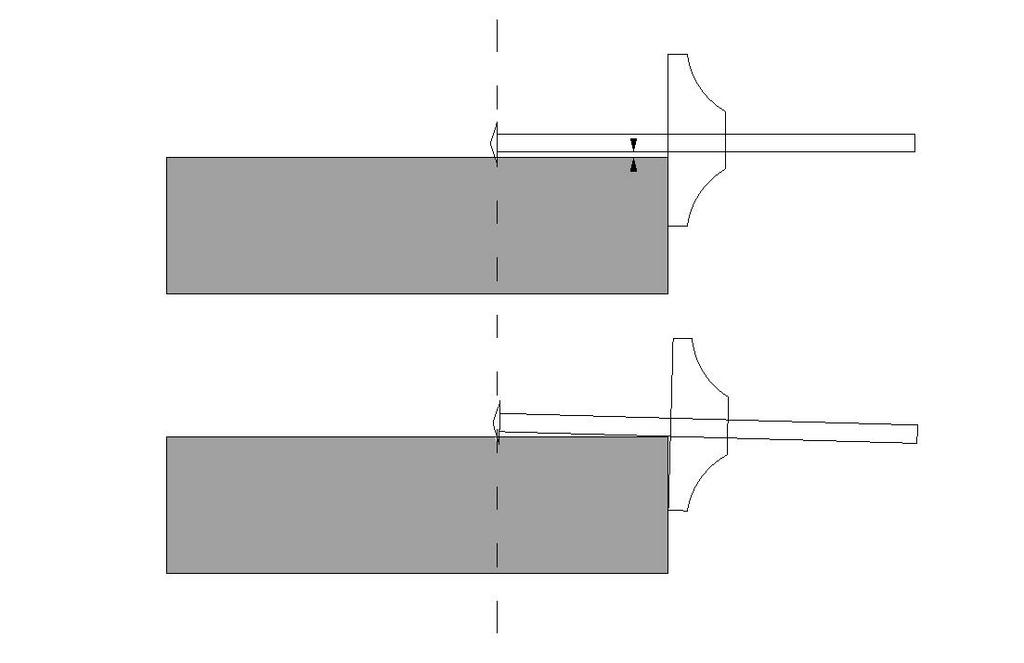

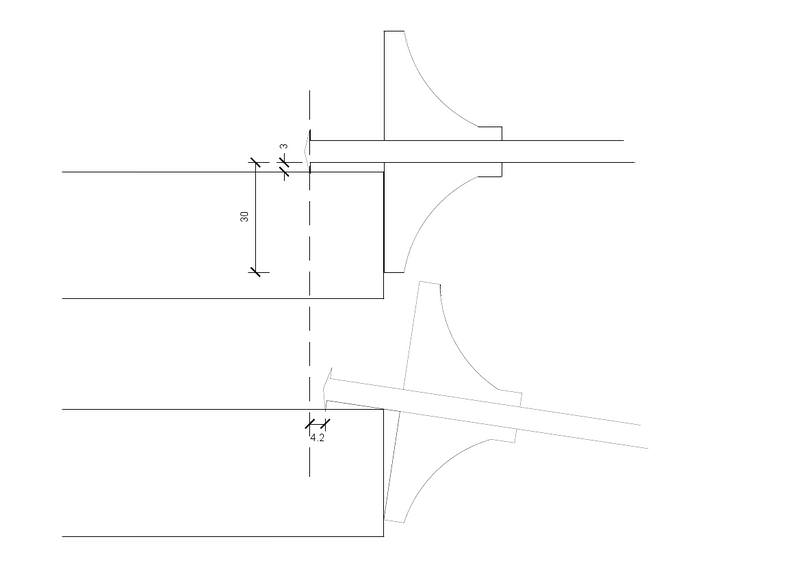

I found the drawings I did illustrating the issue:

MikeG.":r22dksrq said:Well remembered, custard. Yep, it's an expensive thing (and otherwise very well engineered) from Workshop Heaven, but the wheel sticks out 2 or 3mm from the shaft (it isn't in front of me, so I'm guessing). This means the shaft can't be used as a reference, which is pivotal to the proper use of a marking gauge. I have no issues using a pin gauge to mark around corners. However, the wheel gauge does something a pin gauge can't: quickly take an absolute measurement of the thickness of a board, which is of course useful when setting out the cutting depths for tails and pins, and for finger joints (box joints).

Edit:

I found the drawings I did illustrating the issue:

Why not? I see no problem at all.JohnPW":2352i1ii said:MikeG.":2352i1ii said:........ However, the wheel gauge does something a pin gauge can't: quickly take an absolute measurement of the thickness of a board, which is of course useful when setting out the cutting depths for tails and pins, and for finger joints (box joints).

How would you keep it hanging in mid air (as in 3rd drawing)? Looks impossible to me.Edit:

I found the drawings I did illustrating the issue:

I could be wrong but I've always thought a wheel marking gauge is not used in the same way as a pin one.

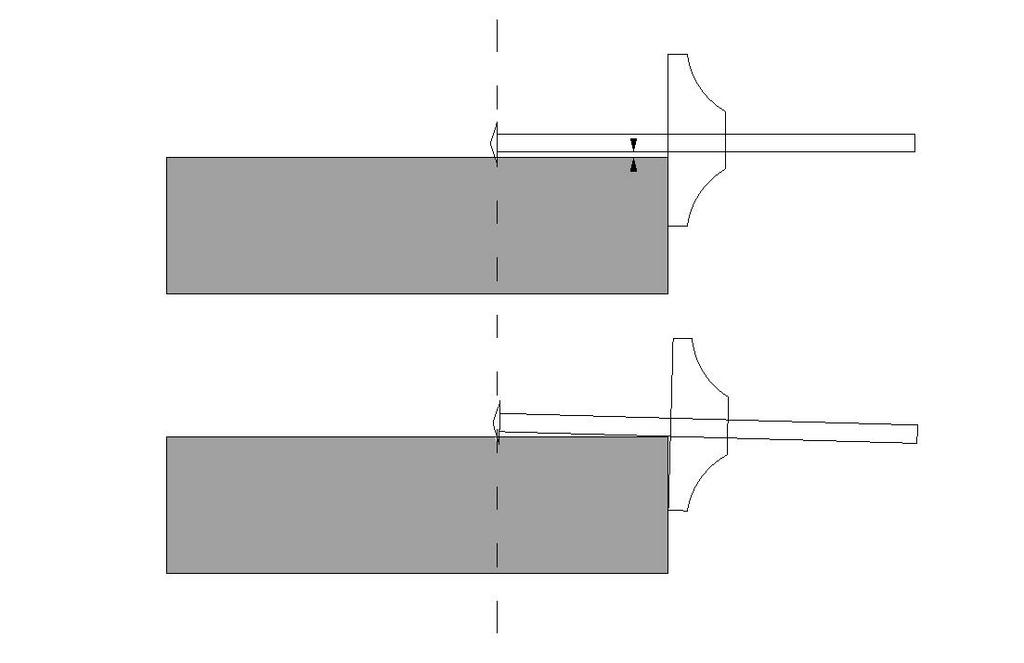

With the pin gauge, you hold the fence against the workpiece and rest the pin stem on the workpiece and rotate it so that pin touches the workpiece. But with a wheel gauge, you only have to hold the fence against the workpiece, the wheel stem "hangs" in mid-air and does not touch the workpiece as you mark the line, as in the first or third drawing.

How would you keep it hanging in mid air (as in 3rd drawing)? Looks impossible to me.

JohnPW":2bm4zxcy said:How would you keep it hanging in mid air (as in 3rd drawing)? Looks impossible to me.

Hold the fence against the workpiece then move the gauge down until the wheel touches. Keep the gauge pressing on the side of the workpiece and move the gauge along the workpiece to make the mark.

JohnPW":2rqygyzb said:How would you keep it hanging in mid air (as in 3rd drawing)? Looks impossible to me.

Hold the fence against the workpiece then move the gauge down until the wheel touches. Keep the gauge pressing on the side of the workpiece and move the gauge along the workpiece to make the mark.

Seems to be a lot of over thinking going on!Beau":3bzbc6zt said:JohnPW":3bzbc6zt said:How would you keep it hanging in mid air (as in 3rd drawing)? Looks impossible to me.

Hold the fence against the workpiece then move the gauge down until the wheel touches. Keep the gauge pressing on the side of the workpiece and move the gauge along the workpiece to make the mark.

Not used a wheel gauge and tend to use a cutting gauge but I use it as you describe. Not especially difficult to learn to do.

JohnPW":19z4p4d1 said:With a pin gauge or a cutting gauge, whether or not the stem/shaft rests on the workpiece depends on how far the pin or knife sticks out.

If they stick out quite a bit, then you have to use the "no stem contact" method, some might say that's the wrong way but it still works.

I expect you can make the "no stem contact" method work but it's much easier the proper way, i.e. "stem contact" all the time and trail the pin/knife.JohnPW":1mt49avd said:With a pin gauge or a cutting gauge, whether or not the stem/shaft rests on the workpiece depends on how far the pin or knife sticks out.

If they stick out quite a bit, then you have to use the "no stem contact" method, some might say that's the wrong way but it still works.

I dont think about but just do it. Sometimes I rest the body on the work sometimes I dont. It's not rocket scienceJacob":31or6fqf said:[Seems to be a lot of over thinking going on!

Enter your email address to join: