CroppyBoy1798

Established Member

I've recently put an extension on the workshop and am in the middle of sorting out the layout, storage etc. The main reason for putting on the extension was for the table saw so that I would have ample room to run long lenghts through the saw without having to haul it outside and back in again (she's damn heavy!!).

Anyway, the saw is a Makita MLT100. Nice little bit of kit, I believe its more of a site saw, but in saying that its very accurate, has a nice sliding carraige setup and a decent mitre guage. It has two extendable tables to the right and rear.

Up to this point I'd never really considered ripping sheets or anything beyond 2ft. But I came up with the idea of making a runoff bench that would attach to the rear of the saw via two 16mm bars (replacing the small extension table that was there). This table would be 2ft wide (the width of the saw), so I go and buy an offcut of a sheet of 18mm MDF, extend the right side table to rip the board down to 2ft and discovered that it would only reach as far as 21" :evil: boy was I annoyed, you'd imagine that at the least it'd reach to 2ft to allow 8x4's to be split in two?

So, to remedy this and to help me in the future I set about making some extensions to help me with this project and future work with large sheet material.

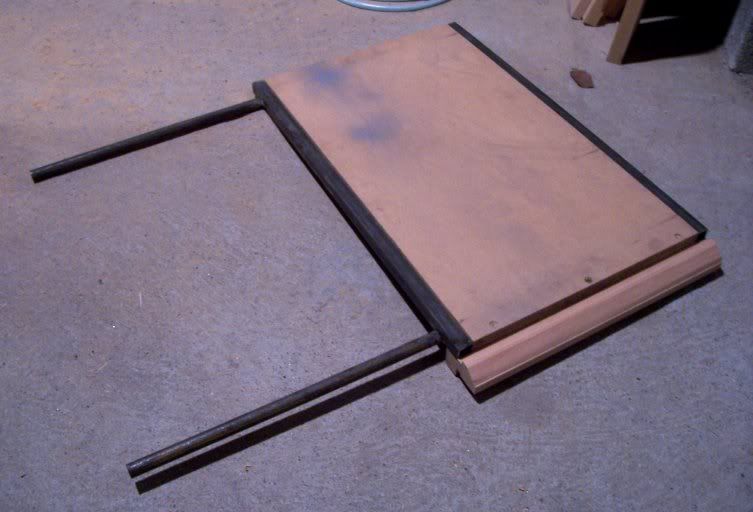

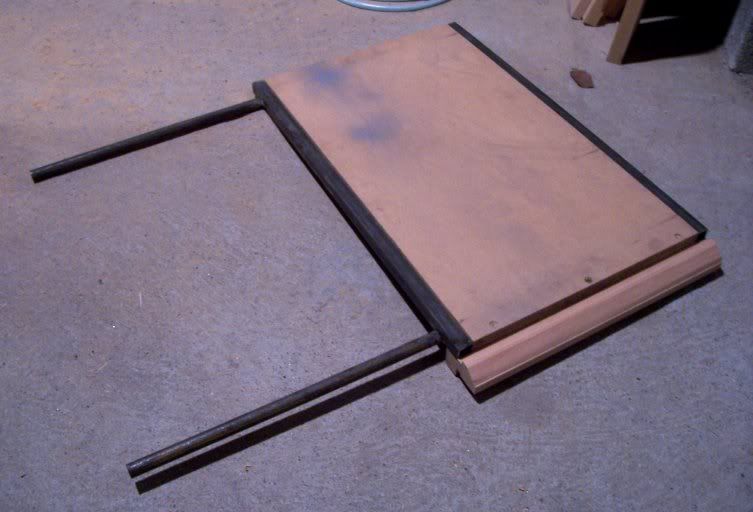

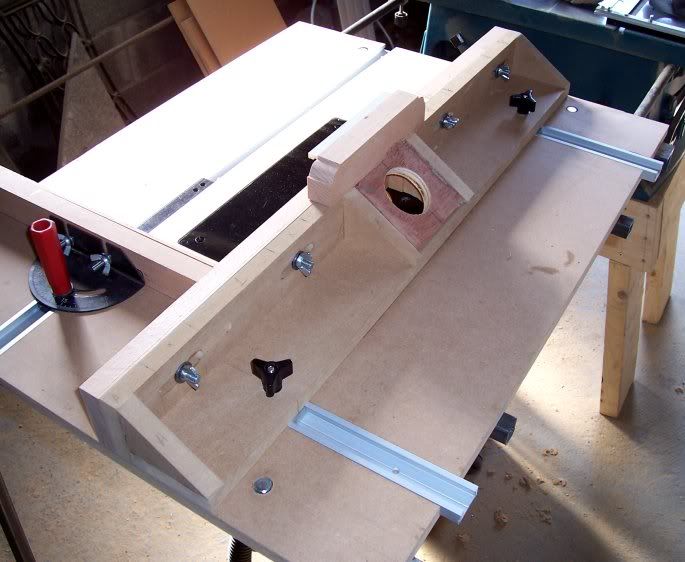

Heres a pic of the standard extension:

Using two 30" lenghts of 16mm solid bar, two lenghts of 20mm box section and a piece of 18mm mdf I was able to put this together. It did mean however verturing over to the dirty, oily and grubby metal working for a while :twisted:. In order for the fence to to used on the new table I made up a beech replica of the aluminium extrusion used on the table saw itself, worked out well and the fence locks good and tight.

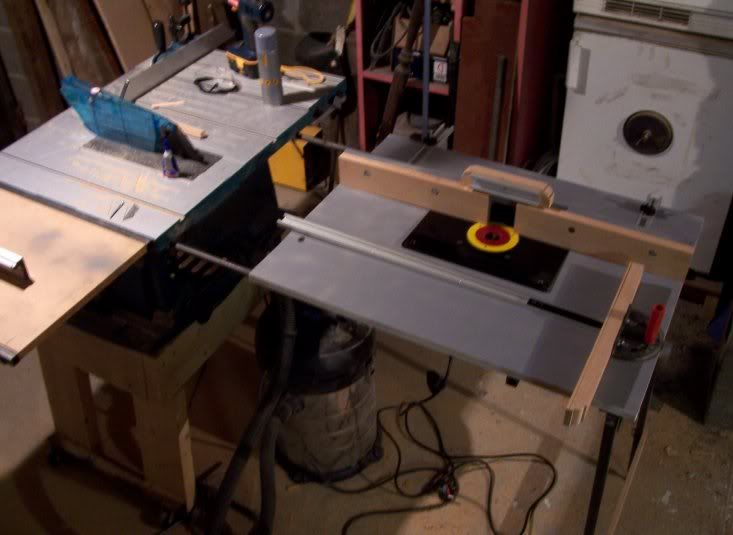

With the new extension I can get a max cut of 22" with the table closed and 32" with it extended! So, with this done I could get down to making my runoff bench which I decided would also become a router table

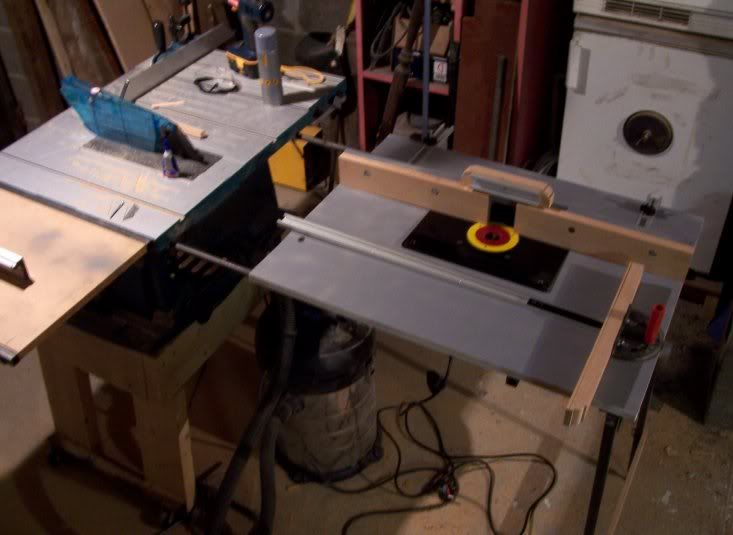

Using the same principle as the side extension I used two lenghts of 16mm bar, a couple of lenghts of 40mm angle iron (from an old bed) and a few lenghts of 20mm box. The table measures 2.5'x2', it can extend back to 32" from the back of the table saw, so, gives good support to longer lenghts of timber. (what did I tell you about the metal working? See the grubby finger prints! :roll: )

When removed the legs can be folded down so the bench can be hung up to give me more floor space if required.

I made this table the same height as the table of the table saw, but, in hindsight I probably should have left it 6mm below the level so that when it was being used as a runoff bench I could fix a sheet of 6mm ply to it to protect the router table top, or if it was being used as a work/assembly table. But then, in saying that having it the height of the table saw table will be handy if I'm routing long lenghts as I can then use the tablesaw as a runoff bench for the router.

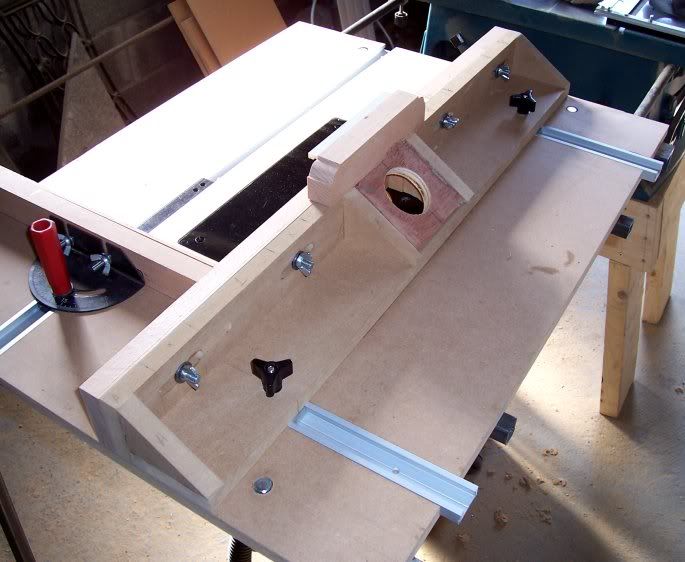

The router table

And here she is after getting her first coat of grey primer! I just sat all the components on it for now, so it looks a little rough here. Its gonna get another few coats of primer, then sprayed black and finally lacquered, then edged with oak.

I might add a side extion to the right side of the router/runoff bench to support any long lenghts that I might be cutting in the future, this, like the right hand extion to the table saw will probably have a single, adjustable leg just for strenght. When I'm done and given the metal work a good clean up I'll spray it all the Makita color and match it in.

So, all in all I have a pretty decent cutting setup now, a lot more than what the saw was offering as standard.

More pics to follow when complete :wink:

Anyway, the saw is a Makita MLT100. Nice little bit of kit, I believe its more of a site saw, but in saying that its very accurate, has a nice sliding carraige setup and a decent mitre guage. It has two extendable tables to the right and rear.

Up to this point I'd never really considered ripping sheets or anything beyond 2ft. But I came up with the idea of making a runoff bench that would attach to the rear of the saw via two 16mm bars (replacing the small extension table that was there). This table would be 2ft wide (the width of the saw), so I go and buy an offcut of a sheet of 18mm MDF, extend the right side table to rip the board down to 2ft and discovered that it would only reach as far as 21" :evil: boy was I annoyed, you'd imagine that at the least it'd reach to 2ft to allow 8x4's to be split in two?

So, to remedy this and to help me in the future I set about making some extensions to help me with this project and future work with large sheet material.

Heres a pic of the standard extension:

Using two 30" lenghts of 16mm solid bar, two lenghts of 20mm box section and a piece of 18mm mdf I was able to put this together. It did mean however verturing over to the dirty, oily and grubby metal working for a while :twisted:. In order for the fence to to used on the new table I made up a beech replica of the aluminium extrusion used on the table saw itself, worked out well and the fence locks good and tight.

With the new extension I can get a max cut of 22" with the table closed and 32" with it extended! So, with this done I could get down to making my runoff bench which I decided would also become a router table

Using the same principle as the side extension I used two lenghts of 16mm bar, a couple of lenghts of 40mm angle iron (from an old bed) and a few lenghts of 20mm box. The table measures 2.5'x2', it can extend back to 32" from the back of the table saw, so, gives good support to longer lenghts of timber. (what did I tell you about the metal working? See the grubby finger prints! :roll: )

When removed the legs can be folded down so the bench can be hung up to give me more floor space if required.

I made this table the same height as the table of the table saw, but, in hindsight I probably should have left it 6mm below the level so that when it was being used as a runoff bench I could fix a sheet of 6mm ply to it to protect the router table top, or if it was being used as a work/assembly table. But then, in saying that having it the height of the table saw table will be handy if I'm routing long lenghts as I can then use the tablesaw as a runoff bench for the router.

The router table

And here she is after getting her first coat of grey primer! I just sat all the components on it for now, so it looks a little rough here. Its gonna get another few coats of primer, then sprayed black and finally lacquered, then edged with oak.

I might add a side extion to the right side of the router/runoff bench to support any long lenghts that I might be cutting in the future, this, like the right hand extion to the table saw will probably have a single, adjustable leg just for strenght. When I'm done and given the metal work a good clean up I'll spray it all the Makita color and match it in.

So, all in all I have a pretty decent cutting setup now, a lot more than what the saw was offering as standard.

More pics to follow when complete :wink: