You won't find a riving knife or a guard on my table saw. Both severely limit the range of tasks the machine can do.

The crown guard on my SIP is not on my SIP! As Bob says they can get in the way and obstruct vision, which is not good.

The riving knife is used when ripping long stuff otherwise is hung on the side of the cabinet.

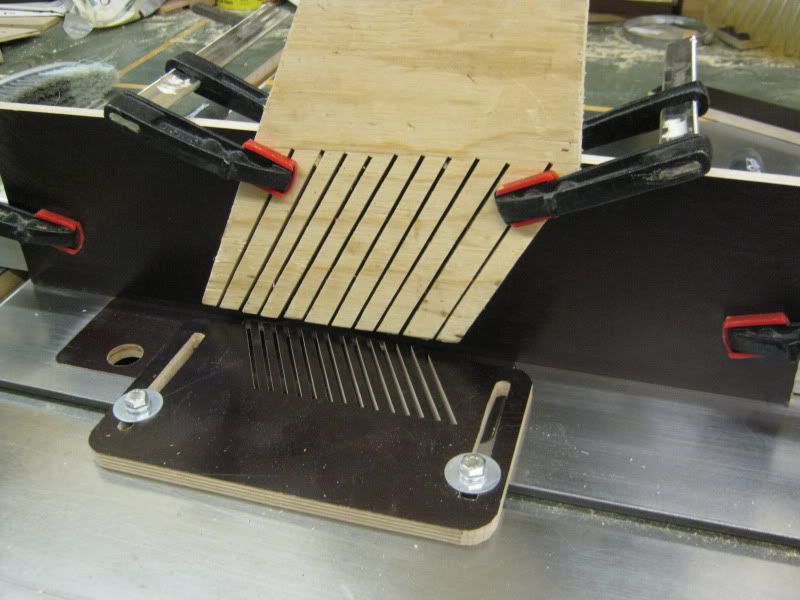

Nearly all my cutting, other than ripping, is done using jigs of some kind, and without a riving knife as it protrudes above the blade making jigs correspondingly higher and heavier.

Pushing a largish sled keeps my hands well away from the blade.

Roy.