Hattori-Hanzo

Established Member

Thanks Ian.

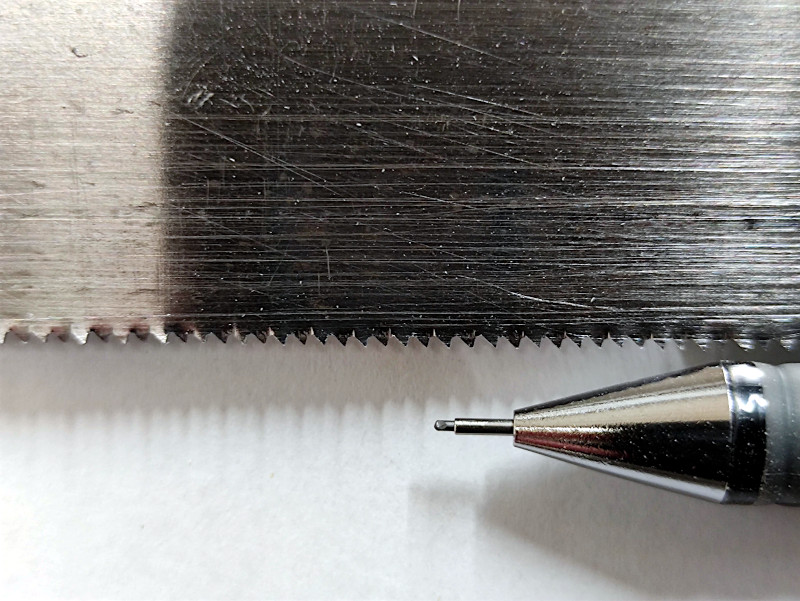

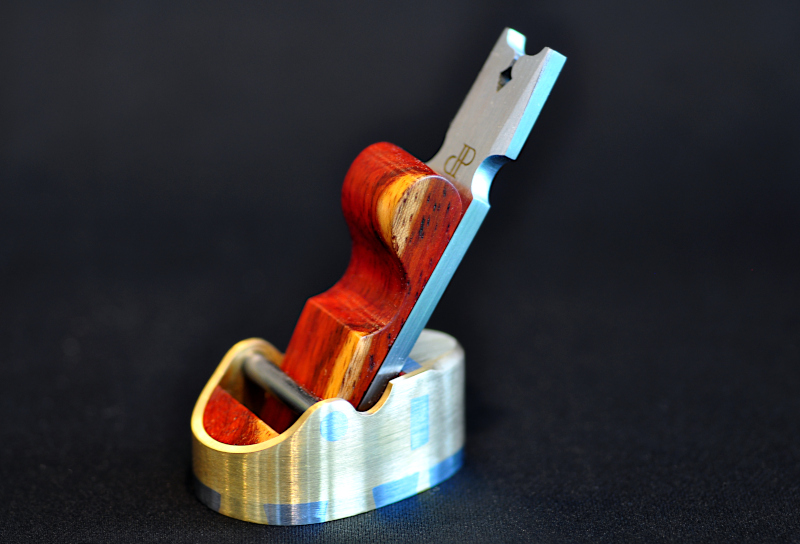

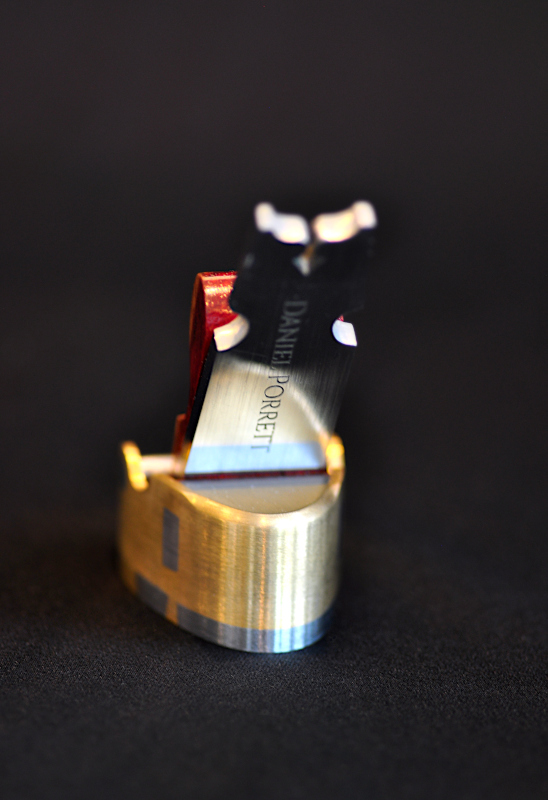

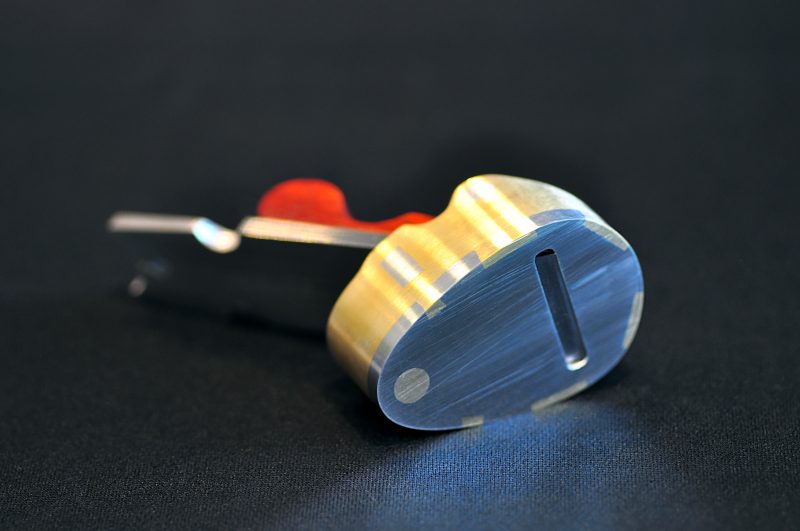

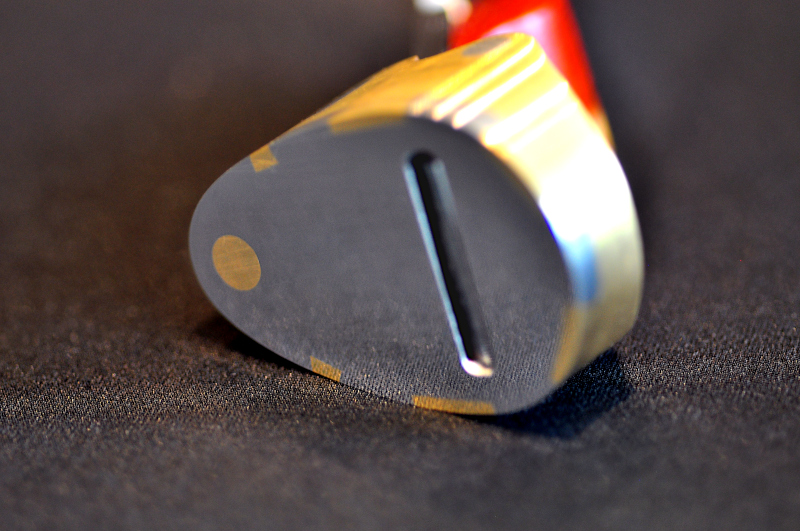

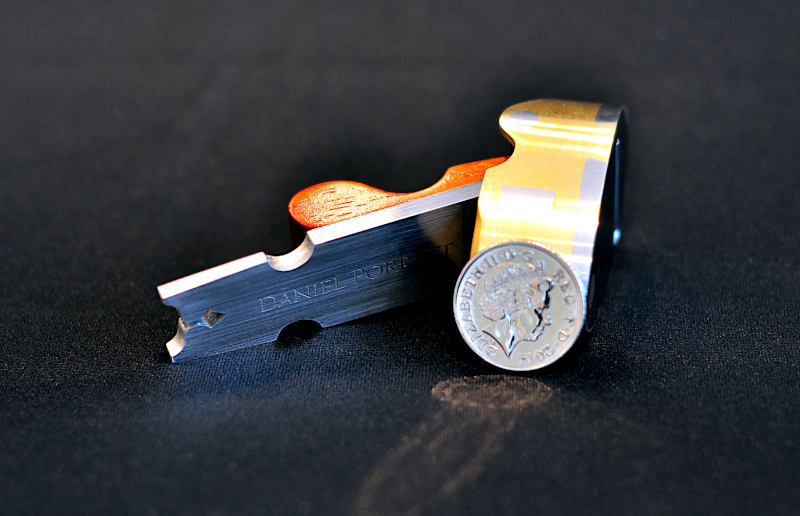

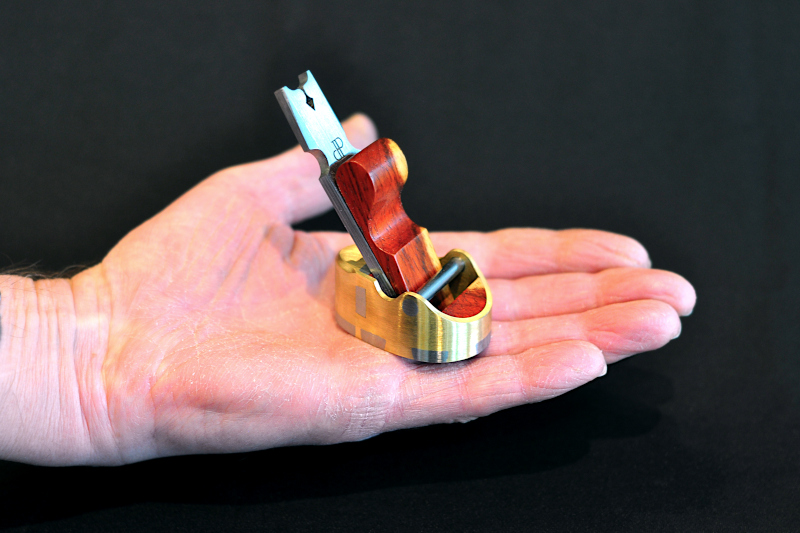

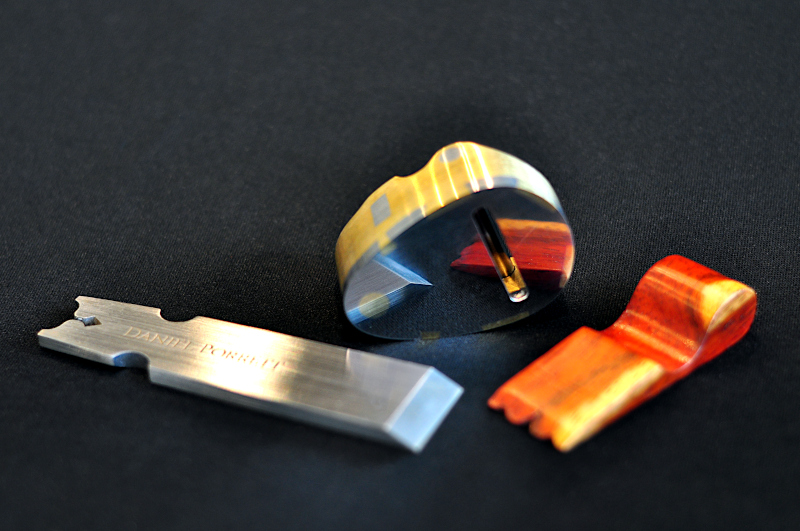

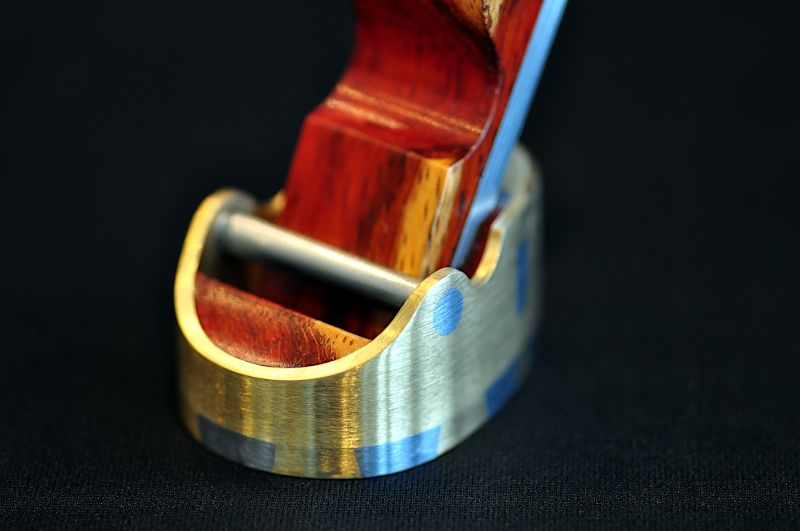

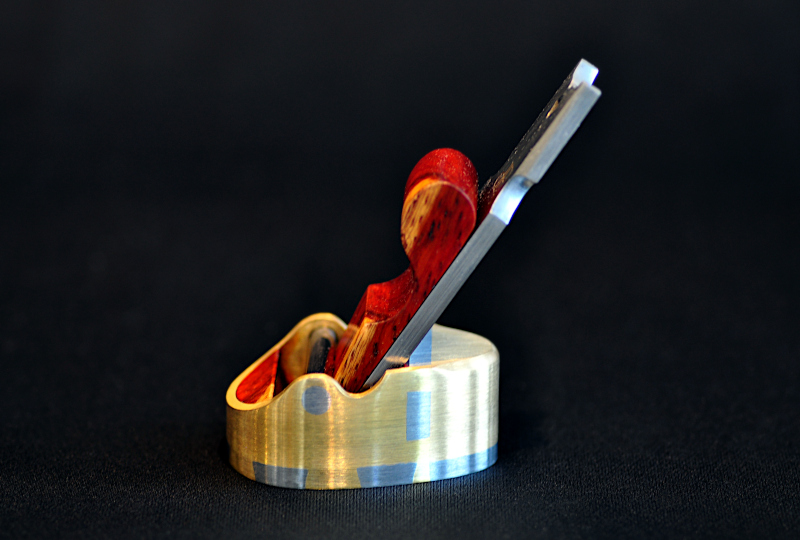

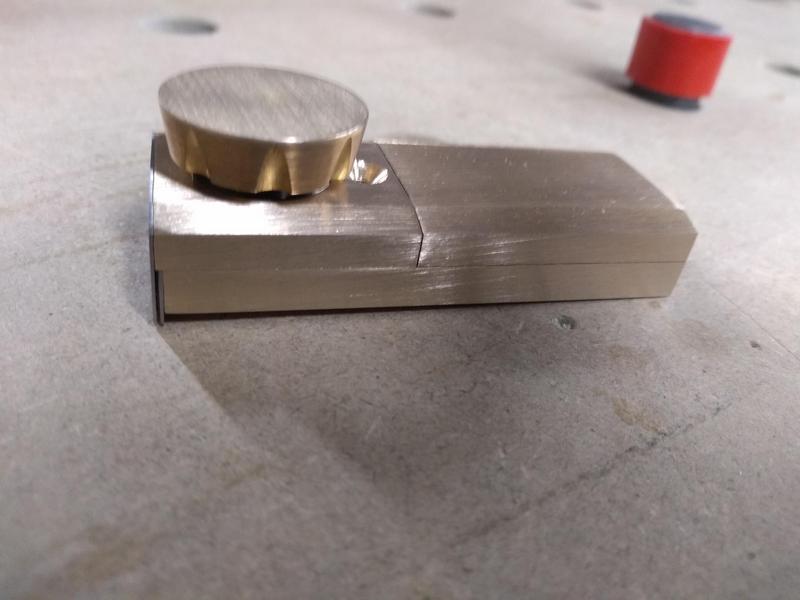

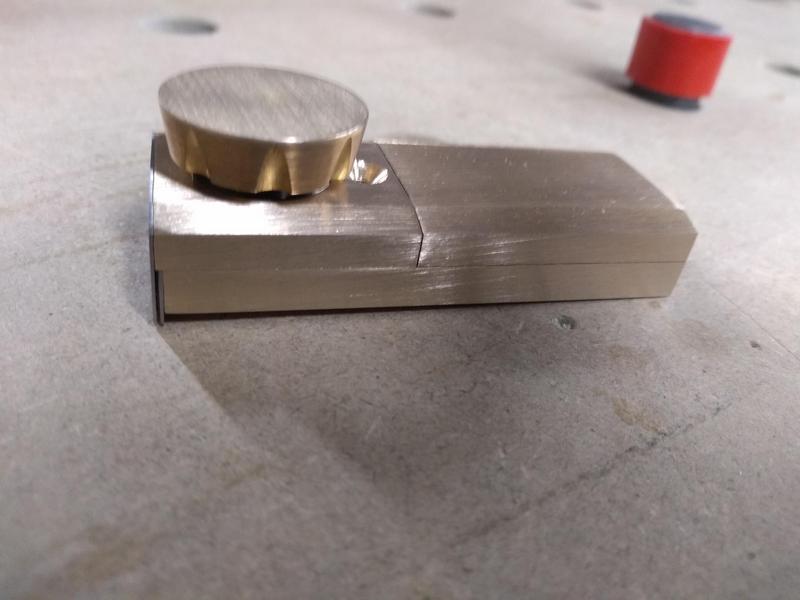

Yes the second plate back hangs down by 1.5mm so as to catch in the saw cut.

You can just make it out in this photo.

I use eclipse junior hacksaw blades to cut the notches. I knock the set off of them completely and grind down half way of the first inch of teeth.

This gets the cuts as narrow as possibly and grinding the teeth helps the saw to start.

I did manage to cut one of my saw plates with a hacksaw and a 32tpi blade but I had to keep it low in the vice to stop it screeching and binding, I could only cut a few mm at a time then I had to reposition it in the vice, it took forever!

I used an angle grinder after that but to be honest I'm not fond of them, too noisy and messy.

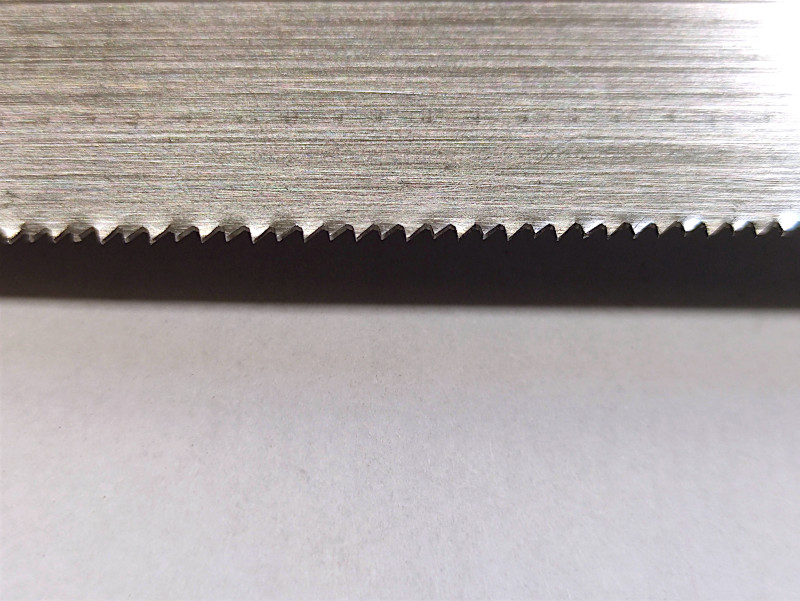

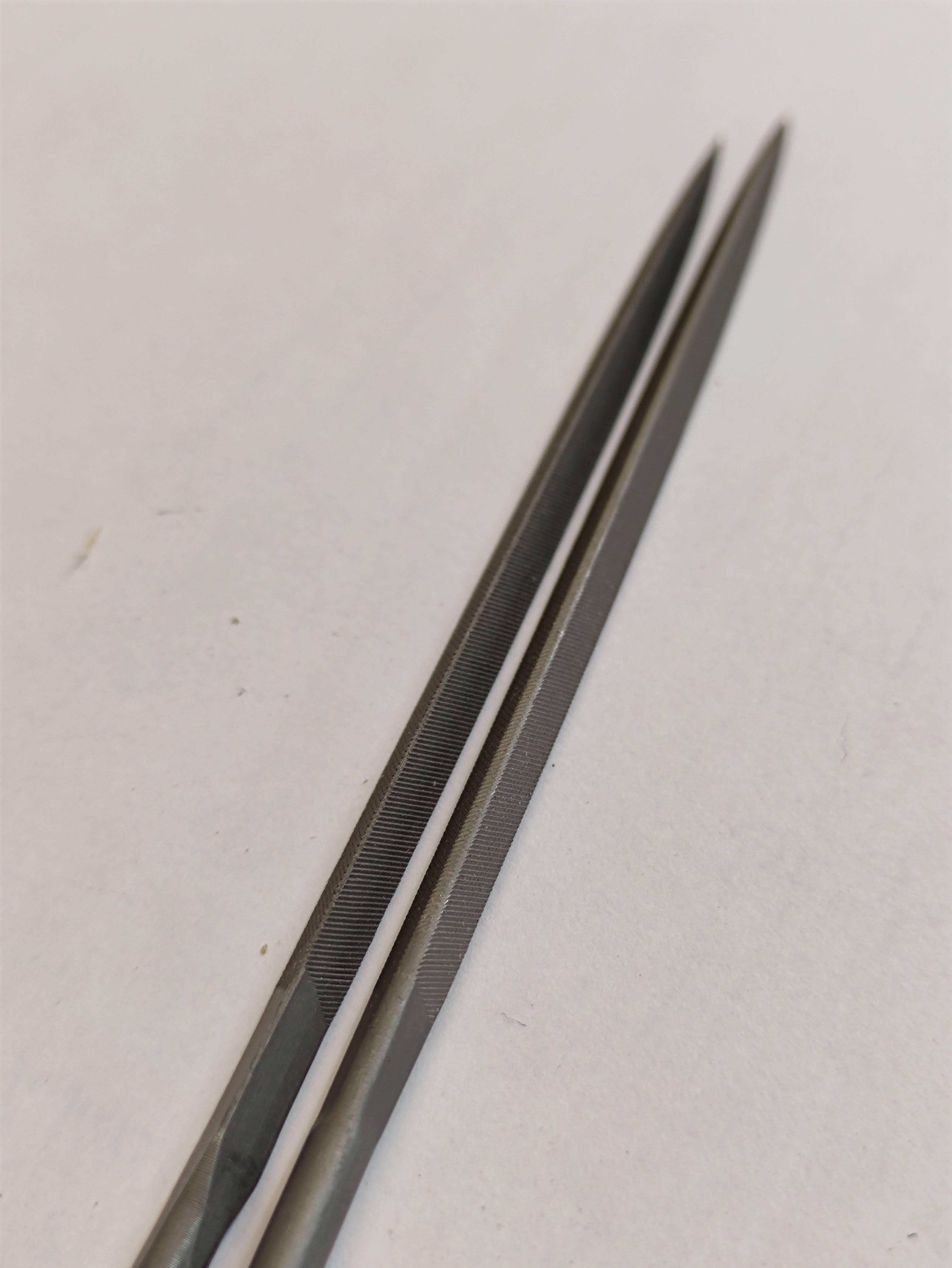

I too was surprised by the profile on the Vallorbe. I had another look at it today and took some pictures next to the Bahco for reference.

The Bahco is on the left. You can see how much wider the Vallorbe is on the "narrow" edge compared to the Bahco.

The Bahco comes to a much finer edge, which I felt made it better for higher TPI sets. Same as you I don't like small pointy teeth with huge gullets, I find they "grab" more

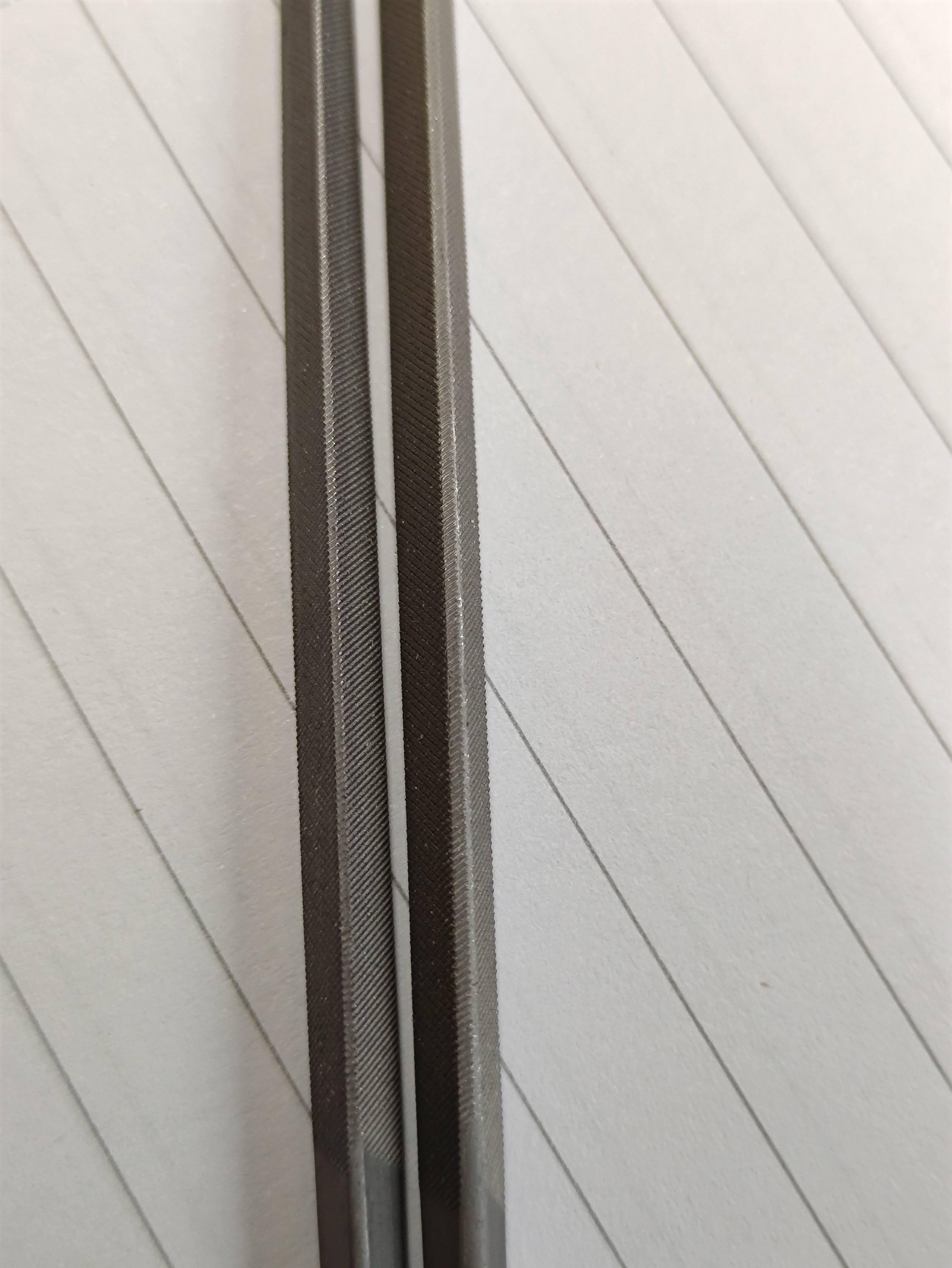

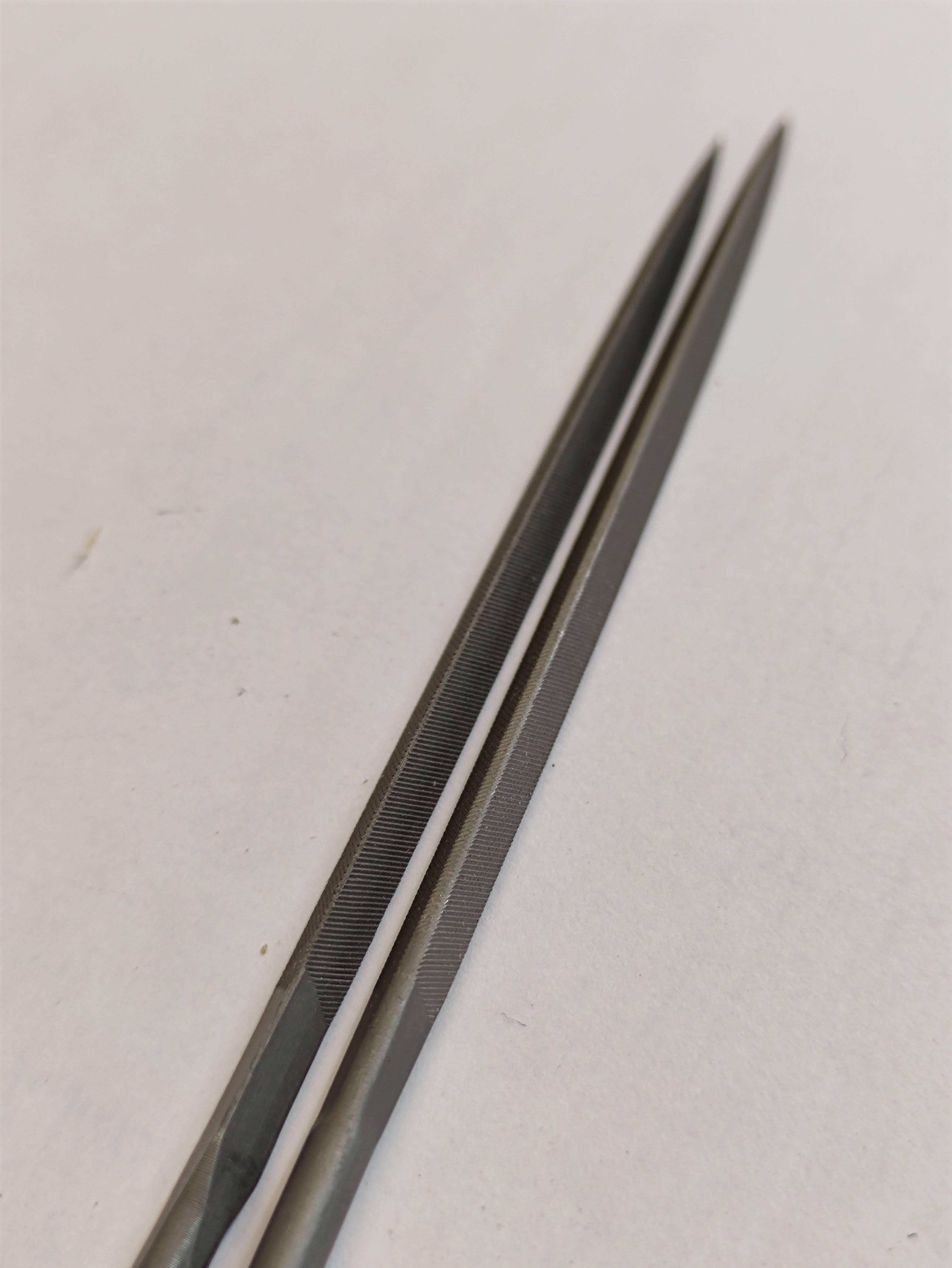

I'd also forgotten that I had already bought a Vallorbe file previously so compared the older one with the newer one.

Bought from the same place under the same listing just at different times.

You can see the older one (which is on the left) comes to a finer edge to. So I'm not sure what's going on with the new vallorbe file, maybe a duff?

Pretty sure its a genuine Vallorbe, it has all the same markings as the slightly older one.

They are great files nonetheless. Very high quality finish and cut very nicely, like I say I think they would be best suited to saws around 12tpi

However I think the Bahco will be my new favourite for saw sharpening, I'm really impressed with it, cuts brilliantly and has the best profile for me for higher tpi saws.

It may even cut 32tpi but I don't want to go there......yet

Good tips on not cutting the teeth to full depth as you go. Like you say it's better to do a few strokes then come back and refine them once they are set out, this way you give yourself the best chance of getting them even.

Thanks again for your reply I really appreciate it.

Cheers.

Yes the second plate back hangs down by 1.5mm so as to catch in the saw cut.

You can just make it out in this photo.

I use eclipse junior hacksaw blades to cut the notches. I knock the set off of them completely and grind down half way of the first inch of teeth.

This gets the cuts as narrow as possibly and grinding the teeth helps the saw to start.

I did manage to cut one of my saw plates with a hacksaw and a 32tpi blade but I had to keep it low in the vice to stop it screeching and binding, I could only cut a few mm at a time then I had to reposition it in the vice, it took forever!

I used an angle grinder after that but to be honest I'm not fond of them, too noisy and messy.

I too was surprised by the profile on the Vallorbe. I had another look at it today and took some pictures next to the Bahco for reference.

The Bahco is on the left. You can see how much wider the Vallorbe is on the "narrow" edge compared to the Bahco.

The Bahco comes to a much finer edge, which I felt made it better for higher TPI sets. Same as you I don't like small pointy teeth with huge gullets, I find they "grab" more

I'd also forgotten that I had already bought a Vallorbe file previously so compared the older one with the newer one.

Bought from the same place under the same listing just at different times.

You can see the older one (which is on the left) comes to a finer edge to. So I'm not sure what's going on with the new vallorbe file, maybe a duff?

Pretty sure its a genuine Vallorbe, it has all the same markings as the slightly older one.

They are great files nonetheless. Very high quality finish and cut very nicely, like I say I think they would be best suited to saws around 12tpi

However I think the Bahco will be my new favourite for saw sharpening, I'm really impressed with it, cuts brilliantly and has the best profile for me for higher tpi saws.

It may even cut 32tpi but I don't want to go there......yet

Good tips on not cutting the teeth to full depth as you go. Like you say it's better to do a few strokes then come back and refine them once they are set out, this way you give yourself the best chance of getting them even.

Thanks again for your reply I really appreciate it.

Cheers.