You can cut superb dovetails with cheaper saws, but if you're new to dovetailing you'll find it easier to cut accurately and confidently with a Knew Concepts saw.

The reason is that the blade tension can be much higher, which keeps the blade straighter. With cheaper saws the blade sags and you need to pay a lot more attention to stop yourself drifting away from the cut line. After you've used a cheaper saw for a while the correction necessary becomes second nature, but in the early days you want things to be as straightforward as possible.

Do you need the swivel angle adjuster? For most furniture scale drawers no you don't, and for the occasional larger project you can twist the blade at each end to 45 degrees with a pair of pliers.

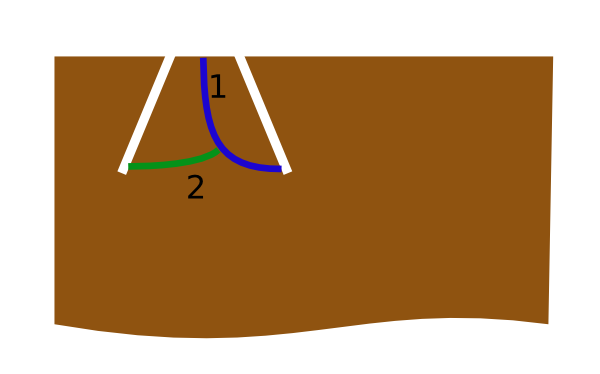

Couple of other points. The wider the throat the weaker the tension, and tension is what you need, so don't get a throat any bigger than necessary or you'll compromise the main reason for buying a Knew Concept saw in the first place. Blades are important, the Pegas ones are terrific, and don't get something too fine. The quicker you cut the more accurately you'll cut, at least in the beginning, and clearing the waste isn't a finish cut, for that you'll use a chisel, so a rough surface really isn't a problem. I tend to make a third cut with my dovetail saw in the centre of the waste and then cut out from that central point towards the corners of the tails with a fret saw, it takes a fraction longer but as I fit my dovetails straight from the dovetail saw with no paring it keeps the corners cleaner and prevents any damage caused by twisting the fret saw into the cut.

It's good to hear from someone cutting dovetails without a jig, smart decision, it's really not difficult and it opens the door to lots more joints and projects.

Good luck!