bugbear

Established Member

Tony":2ksmzona said:A professioanl woodworker cuts the wood, finds it is too thick, knocks the fence over a bit and cuts again so it fits

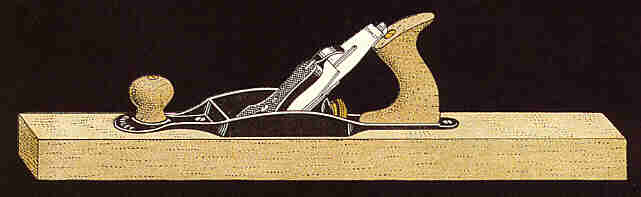

An amateur (he called them weekend woodworkers) cuts the wood a bit thick and then spends 2 hours hand planing it to size

Of course, the purpose of the professional is to make an item, and make a profit.

The motives of amateurs are more varied, I'm happy to say.

I'm fairly sure no professional would have done this...

(by Lord Nibbo)

BugBear