David C":2b6uyytv said:

My sharpening time for Japanese chisels is exactly the same as for my European chisels!

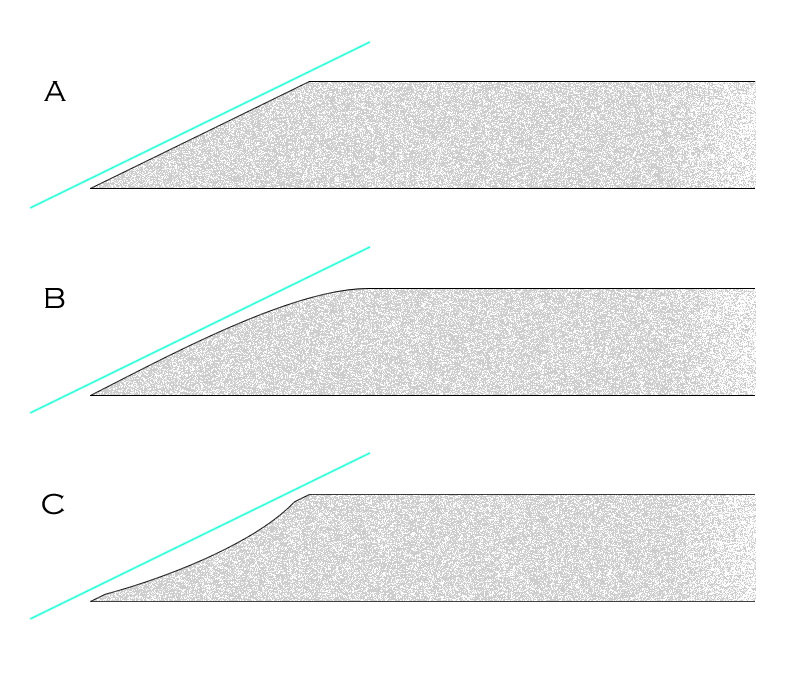

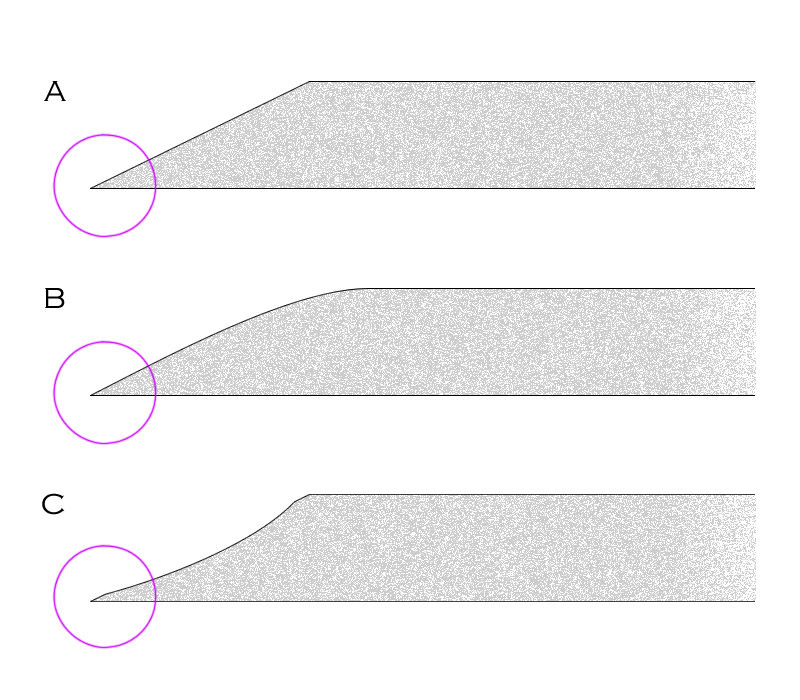

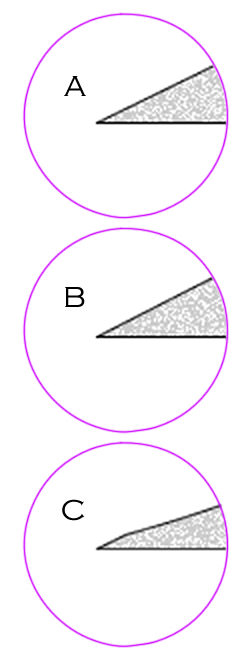

I have no use for the single polished bevel.

It is clear that Japanese chisels are better when one works dense exotic timbers.

best wishes,

David

Mine differs because it's only about 30 seconds for a western chisel, and enough time needs to be spent on japanese chisels at some point to grind the bevel.

However, I've found that japanese chisels that are a touch soft will sharpen fantastically on a single washita stone. It can't cut them deeply, so they are still blindingly sharp. I also deal natural stones (mostly japanese), so I've got just about everything on hand, but really like the washita - very practical and something pretty horrid has to happen to a japanese chisel for it to be too slow. It also preserves the visually rewarding single bevel as well as the look of a natural stone with stark contrast.

I do use the japanese chisels when making plane mortises in beech. A mortise, 15 seconds on a washita, another mortise, 15 seconds on a washita. It's a really nice circle. I don't have many western chisels that are as stout and short, or I'd probably use them, too. (there is a conflict in my statement here about time, but mortising a plane is a different thing -it is an exercise in abuse, and chasing the finest edge and trying to keep it is not productive - a quick touch up to correct an edge is just fine. Smaller and finer joinery, that's not really the case, and the penalty is large if you chip the corner of the hardest chisels, like the older ouchis).

What I've found over the years for exotics (again from plane making, mortising cocobolo or something particularly hard on the flat sawn face) is that most western chisels will give up at the standard angles, but an additional two or three degrees is all that's needed. At some point (angle steepness) in the exotics, chips fly instead of peeling, and some may find that a bit undesirable. I kind of like it in a plane mortise as those chips exit the mortise with no assistance, but it some of the chips can end up 20 feet away in a corner.

Not debating that japanese chisels are wonderful - I love them all (western and japanese) unless they're improperly hardened or errantly made (i have broken a japanese mortise chisel that wasn't properly welded, and only in routine mortising of cherry). They can be a bit of an indulgence, and I've gone so far as to pick up three kiyotada chisels (two used). At the price most others are brought to us in the US new, I'm out. Too many links in the chain adding price, and thankfully some based in japan have noticed that and begun offering sets for reasonable prices direct shipped, but the makers are protective of their distribution networks, and there are a few over there looking to get "a little extra from gaijin", like a dealer who charges an additional 40% if you read their site in English instead of japanese (based on a plane I once bought for $350, but like other things, was $500 on the site in English). Anyway, not particularly relevant.