You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

How To Cut Mitred or Mitre Dovetails WIP

- Thread starter custard

- Start date

Help Support UKworkshop.co.uk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

screwpainting

Established Member

Thanks for this Custard!

If you ever turn these brilliant tutorials into a book they'll sell like hot cakes.

It really ought be done, I could not agree more. =D> =D>

Benchwayze

Established Member

Great thread Custard. The mitre always adds class to a dovetail.

Nice one.

John

Nice one.

John

Derek Cohen (Perth Oz)

Established Member

Custard, I mentioned this when I posted a build in January this year (2019), that is, I read and re-read your to-do several times before attempting my first mitred through dovetails. The main difference between yours and mine was that you went pins first, and I went tails first. I wanted to thank you again here, but also provide a link to my article for those wanting to do it the “other way”

http://www.inthewoodshop.com/Furniture/ ... able2.html

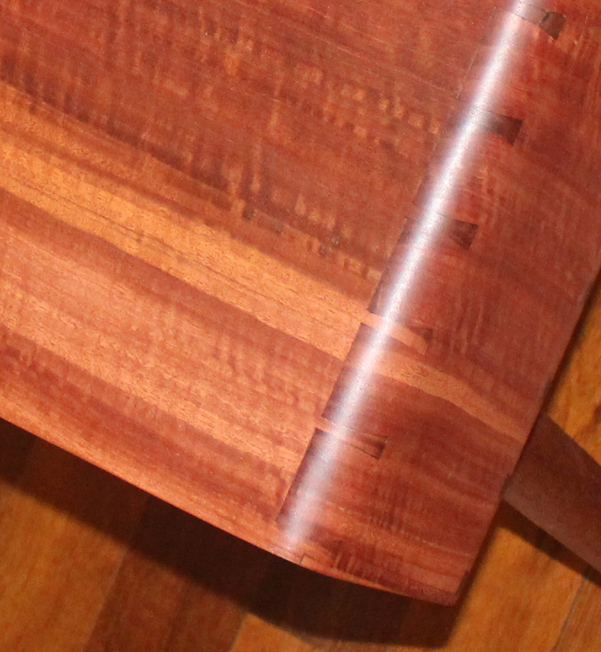

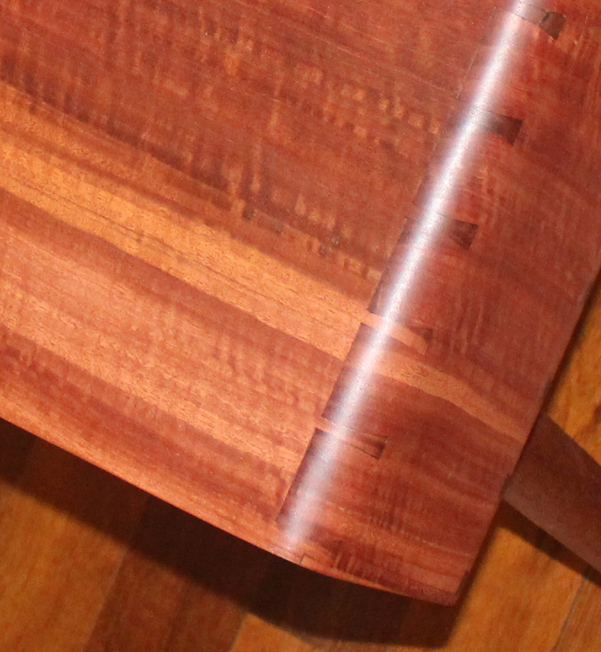

Later in the coffee table build, the table ends were rounded over. The effect of the mitred corners really enhanced the finished piece. This is the start of a joint which will now be used by preference.

Regards from Perth

Derek

http://www.inthewoodshop.com/Furniture/ ... able2.html

Later in the coffee table build, the table ends were rounded over. The effect of the mitred corners really enhanced the finished piece. This is the start of a joint which will now be used by preference.

Regards from Perth

Derek

Bodgers

Established Member

Super craftsmanship, love that mid century design as well, It reminds me of a similar piece done by "snedkersind" (on Instagram) a Danish cabinet maker...

https://www.instagram.com/p/BCvCblxp08K ... _copy_link

https://www.instagram.com/p/BCvCblxp08K ... _copy_link

Derek Cohen (Perth Oz)

Established Member

Super craftsmanship, love that mid century design as well, It reminds me of a similar piece done by "snedkersind" (on Instagram) a Danish cabinet maker...

https://www.instagram.com/p/BCvCblxp08K ... _copy_link

I’ve not seen that before. Beautiful work. The technique I used looks to be the same - adding a curved fillet to the inside corner to create an even thickness when rounding the dovetails.

Regards from Perth

Derek

tomthumbtom8

Established Member

I would like to know if I may what is the thinnest stock acceptable for a dovetail joint

its just a thought

its just a thought

Derek Cohen (Perth Oz)

Established Member

I would like to know if I may what is the thinnest stock acceptable for a dovetail joint

its just a thought

I made this box ...

... for a shoulder plane ...

The sides were 1.5mm thick ...

Regards from Perth

Derek

tomthumbtom8

Established Member

That's sweet Derek

So a beginner would have no trouble with 12mm side walls

So a beginner would have no trouble with 12mm side walls

Glynne

Established Member

So a beginner would have no trouble with 12mm side walls

I'm no beginner but I can have problems with any thickness of walls!

Derek Cohen (Perth Oz)

Established Member

While it may seen that thinner is easier, it can be a lot harder. The square saw cut at the top of the board is the more critical cut. Wider boards make it clearer to see squared lines, and then to saw to them. Thinner boards increase the error of sawing fractionally off line. I would rather learn with 16mm thick boards.

Regards from Perth

Derek

Regards from Perth

Derek

Hi Custard, Great tutorial, thanks for taking the time to do it. The only issue I have is that I can't see you photos. I can however see Derek's (Cohen). Do you know why this is, or perhaps the mods know. Thanks again.