Hi everyone

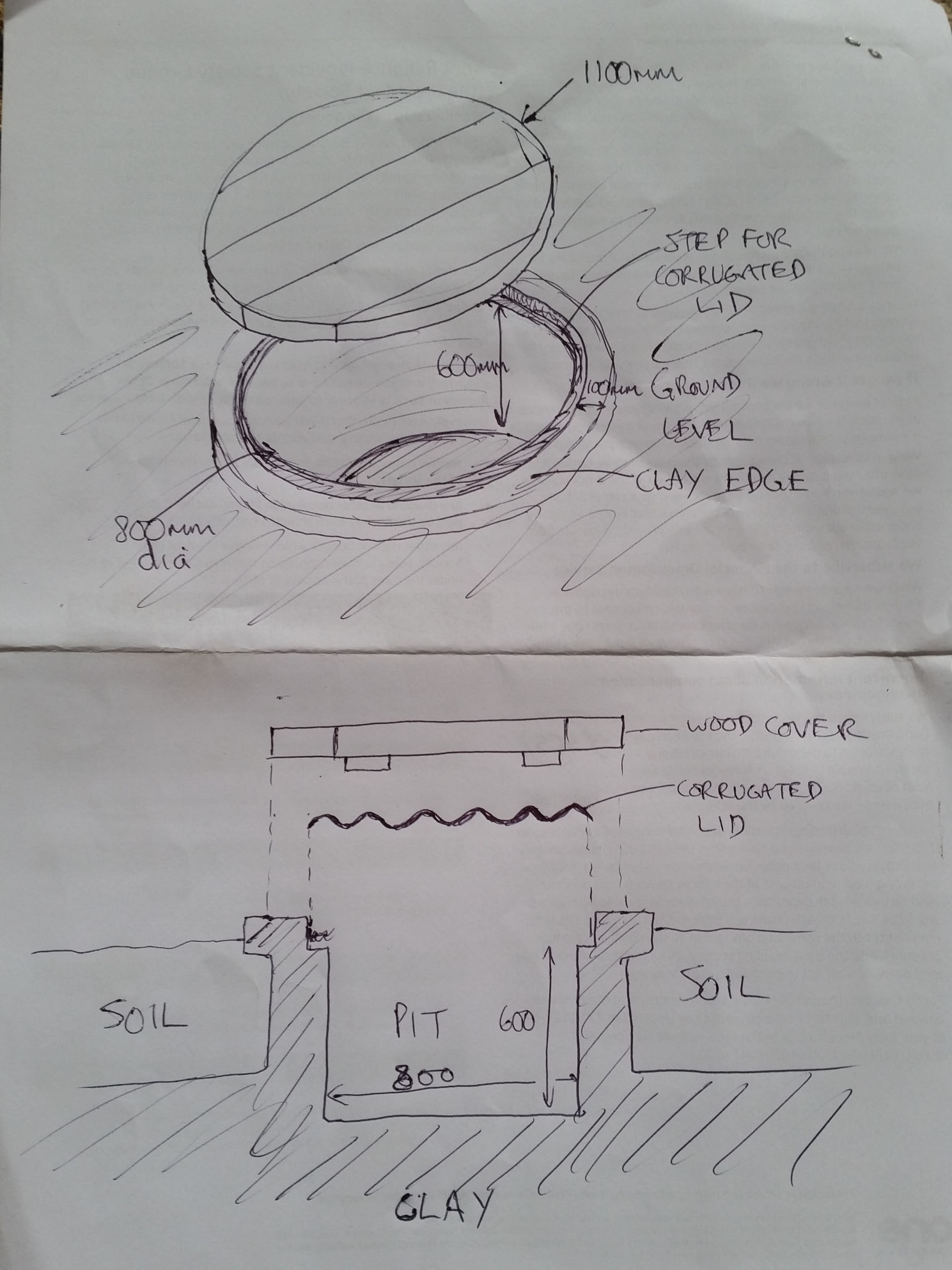

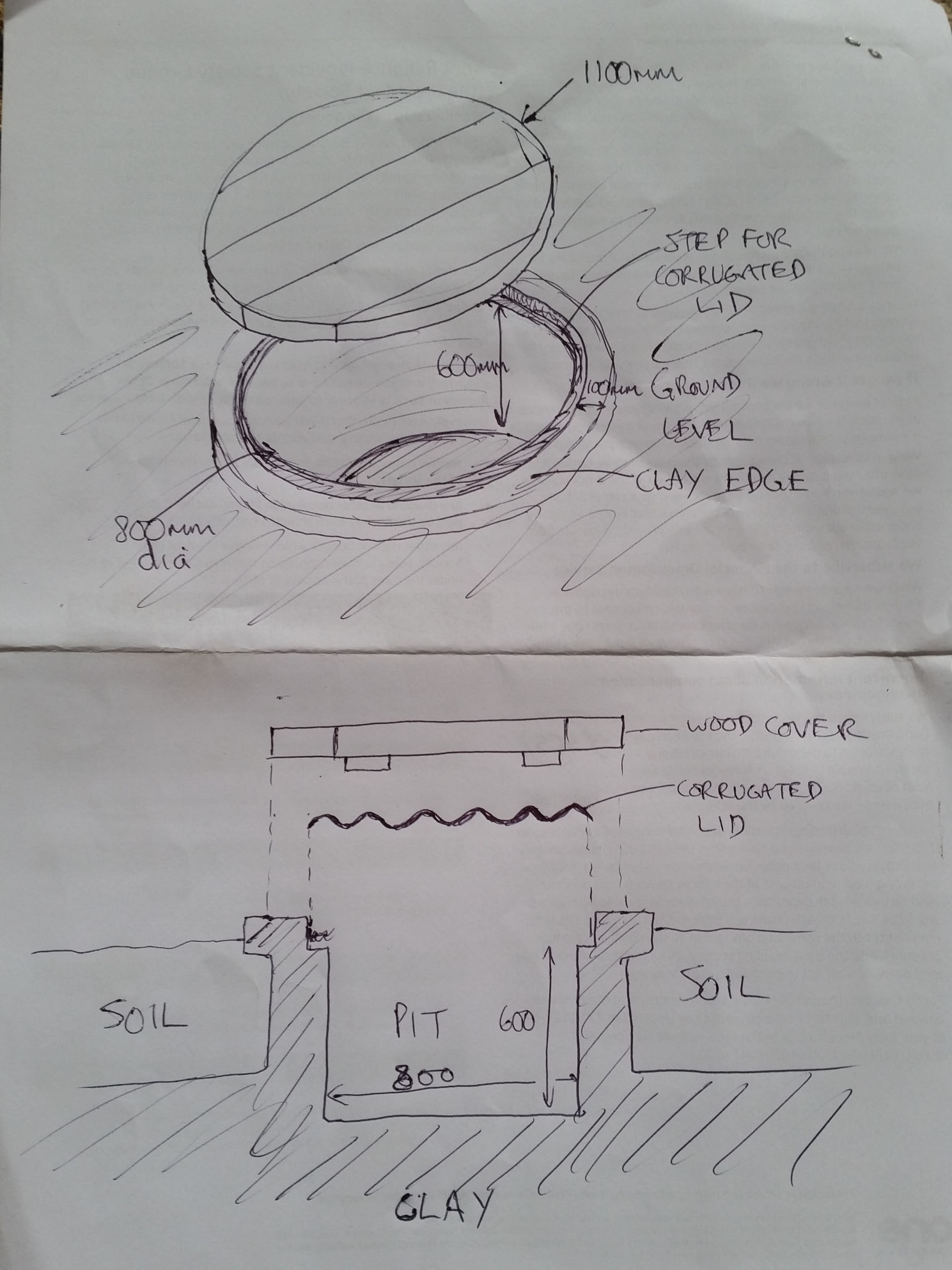

I want a cover for my fire pit/kiln on my allotment. It is quite big, an 800mm wide x 600mm deep hole. I need to protect it from the elements, and more importantly needs to be strong enough to be stood on as I'm certain it will get walked on. It has a clay edge of 100mm for the cover to sit on.

At first I looked at old hardwood round garden tables, but as these get old, they weaken significantly, plus they have small gaps to let the rain through. If this happens I end up with a swamp in the pit.

My current thinking is some large 9" x 2" joists, cut to size, joined on edge and then cut into a circle.

Possibly braced from below, but at present the braces would have to be much less than 2", more like 15mm max as i currently have a corrugated sheet right underneath which is used during the firing to choke out the fire towards the end. I could build up the 100mm clay edge to accept thicker bracing if necessary.

I am hoping a sharp edge, and good wood glue will provide the sealing of the joints, and the timber is treated, so it's more the structural strength in the joints.

And the simpler the better. Ideally I'd make this within a few hours, not over a couple of weekends.

This is only an allotment, doesn't need to be high end carpentry. Just strong and tight.

I only have an electric plane and router, no biscuit joiner. Was assuming T&G, lap joint, dowels, pocket screws & glue etc.

Any ideas welcomed

I want a cover for my fire pit/kiln on my allotment. It is quite big, an 800mm wide x 600mm deep hole. I need to protect it from the elements, and more importantly needs to be strong enough to be stood on as I'm certain it will get walked on. It has a clay edge of 100mm for the cover to sit on.

At first I looked at old hardwood round garden tables, but as these get old, they weaken significantly, plus they have small gaps to let the rain through. If this happens I end up with a swamp in the pit.

My current thinking is some large 9" x 2" joists, cut to size, joined on edge and then cut into a circle.

Possibly braced from below, but at present the braces would have to be much less than 2", more like 15mm max as i currently have a corrugated sheet right underneath which is used during the firing to choke out the fire towards the end. I could build up the 100mm clay edge to accept thicker bracing if necessary.

I am hoping a sharp edge, and good wood glue will provide the sealing of the joints, and the timber is treated, so it's more the structural strength in the joints.

And the simpler the better. Ideally I'd make this within a few hours, not over a couple of weekends.

This is only an allotment, doesn't need to be high end carpentry. Just strong and tight.

I only have an electric plane and router, no biscuit joiner. Was assuming T&G, lap joint, dowels, pocket screws & glue etc.

Any ideas welcomed