Bean

Established Member

Hello all

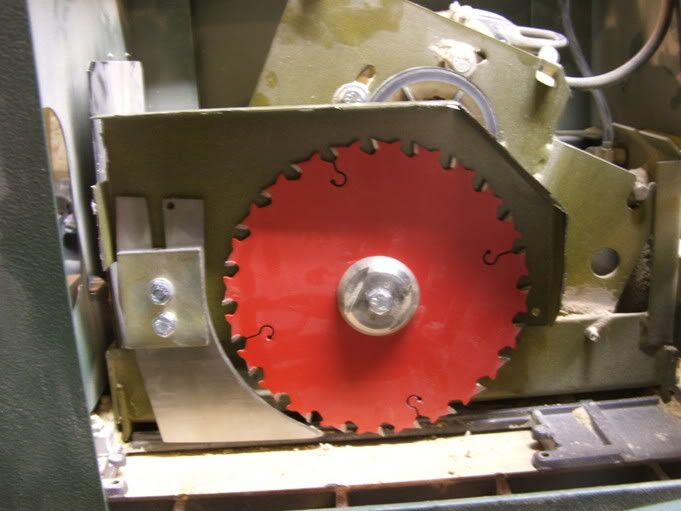

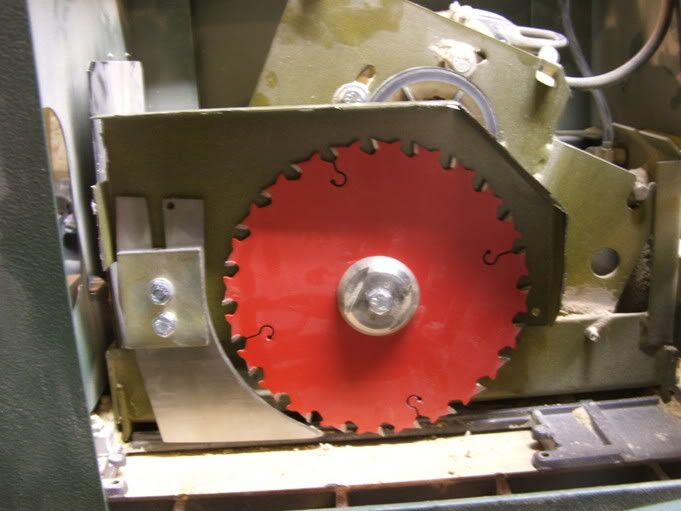

well I have a Kity 419 super saw lousy dust extraction so I have made a mod or two.

Firstly I removed the side panel

I then undid two nut which retained the inner blade guard

I ground off the welds and removed the dust port and one side of the guard

I replaced the section with the studs as it provided a barrier between the belt and the saw blade

I then started to fit the new dust chute and cover

made by a friendly local fabricator.

Nearly at the end now, Covers in place, sealed and bolted down

and it works made a couple of cuts saw body is now largely sealed, dust is not escaping through the other holes in the casing as the extractor creates a negative pressure.

I hope this is useful to other Kity owners who are looking to keep Kity clean

Bean

well I have a Kity 419 super saw lousy dust extraction so I have made a mod or two.

Firstly I removed the side panel

I then undid two nut which retained the inner blade guard

I ground off the welds and removed the dust port and one side of the guard

I replaced the section with the studs as it provided a barrier between the belt and the saw blade

I then started to fit the new dust chute and cover

made by a friendly local fabricator.

Nearly at the end now, Covers in place, sealed and bolted down

and it works made a couple of cuts saw body is now largely sealed, dust is not escaping through the other holes in the casing as the extractor creates a negative pressure.

I hope this is useful to other Kity owners who are looking to keep Kity clean

Bean