Eric The Viking

Established Member

- Joined

- 19 Jan 2010

- Messages

- 6,599

- Reaction score

- 76

Cor, you lot aren't half a distraction (see other topic...)!

Wot I really wanted to ask about was this:

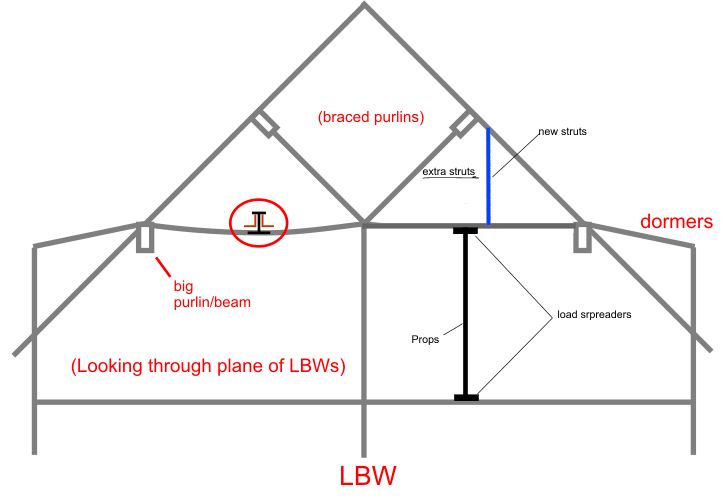

Like a twit I put too much stuff in the attic recently and nearly brought the ceiling(s) down. I've got a cunning plan, as ever, to strengthen them, but it involves hanging the ceiling joists from two L-shaped steel RSJs, like this:

I've only shown one ceiling joist - the pair of steels (pinky-red) runs across the middle of the ceiling, picking up all the joists.

Trouble is- that I can only guess at what size of steel I should specify. I've found some calculators on the net, but they assume either "I" or "U" section RSJs, which won't work here (well, "U" might but it's would probably be heavy and hard to manoeuver). I can't lift tiles, etc. to get an RSJ in - it's too high up and too awkward to reach, so everything has to get through a small loft access.

I also have to do it this way (or something like this) because it eliminates most of the need for accurate drilling of steel when it's up in the loft. It sort-of aligns itself, or so I hope.

So can anyone either suggest a calculator, or give me an idea of where to go for formulae?

Many thanks,

E.

Wot I really wanted to ask about was this:

Like a twit I put too much stuff in the attic recently and nearly brought the ceiling(s) down. I've got a cunning plan, as ever, to strengthen them, but it involves hanging the ceiling joists from two L-shaped steel RSJs, like this:

I've only shown one ceiling joist - the pair of steels (pinky-red) runs across the middle of the ceiling, picking up all the joists.

Trouble is- that I can only guess at what size of steel I should specify. I've found some calculators on the net, but they assume either "I" or "U" section RSJs, which won't work here (well, "U" might but it's would probably be heavy and hard to manoeuver). I can't lift tiles, etc. to get an RSJ in - it's too high up and too awkward to reach, so everything has to get through a small loft access.

I also have to do it this way (or something like this) because it eliminates most of the need for accurate drilling of steel when it's up in the loft. It sort-of aligns itself, or so I hope.

So can anyone either suggest a calculator, or give me an idea of where to go for formulae?

Many thanks,

E.