I think I might have worked out how to post pictures now

Here is the text from Yahoo page:-

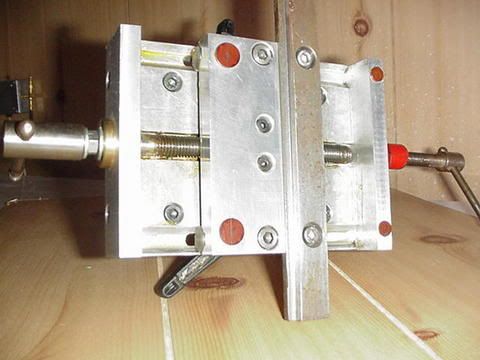

I will shortly be posting some photos of my jig. Hopefully the

pictures will be self explanatory. The stock clamp was made from a

cheap imported G clamp but with a newly cut thread (perpendicular to

the fixed jaw this time!) and a screwcut steel threaded section with

alarge elephants foot made to suit. The slide mechanism uses a pair of

V-grooves riding on a round steel bar with a bolt threaded through to

lock the slide on both sides with the black/orange levers. Looking at

the underside view, the adjustment screw can be seen and also note the

four Tufnol pads that bear on the table when in use. These allow an

easy sliding action and prevent problems due to build up of sawdust

under the jig which could give cutting errors. The pads are glued into

holes in the carriage and then once the adhesive has hardened are

given a light machining over the surface to ensure the jig runs with

the mounting surface perpendicular to the table. The pads stand about

1/32"proud of the carriage surface.

It is of course essential that the table saw blade is set parallel to

the table slot and also perpendicular to the table surface. I anyone

wants more info I will try and help either through this group or

subsequently direct via my mailbox if we run the risk of boring other

members.

Regards

Bob