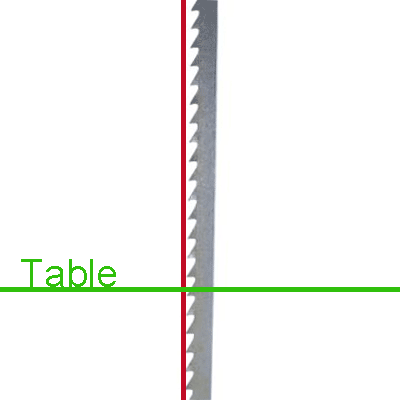

Was wondering how to adjust the table on a saw to make it 90° as at them moment the table is a few degrees out making the cutting of bridle joints just a little out.

Seems the table only allows for tilting left to right, not front to back to correct this?

My saw = Charnwood W715 10'' Woodworking Bandsaw

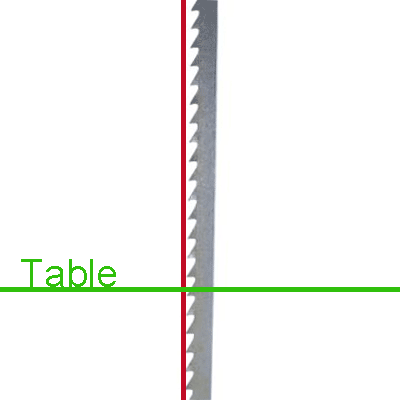

Seems the table only allows for tilting left to right, not front to back to correct this?

My saw = Charnwood W715 10'' Woodworking Bandsaw