Doug B

Shy Tot

they’d soon find out if cutting timber with a high moisture contentMy suggestion is fit Sawstop to all table saws, just don't tell anyone.

Ollie

they’d soon find out if cutting timber with a high moisture contentMy suggestion is fit Sawstop to all table saws, just don't tell anyone.

Ollie

they’d soon find out if cutting timber with a high moisture content

I take it you don't wear a seat-belt in your car ?I don't think this does much for safety, you can never protect a numpty for ever and by instilling a false level of machine safety just means they will be more prone to injury on another machine or when using someone elses saw without that feature. Do you remove your dogs teeth in case it decides to bite or learn to live with it and just understand its temperament!!

Cannot see the connection, what I am saying is you cannot protect someone from themselves if they do not have the right attitude, they are essentially an accident waiting to happen. No mater how much you try and make everything safe you have to accept that life is not risk free and it is your responsibility to remain unharmed and not expect someone else to remove the risk for you.I take it you don't wear a seat-belt in your car ?

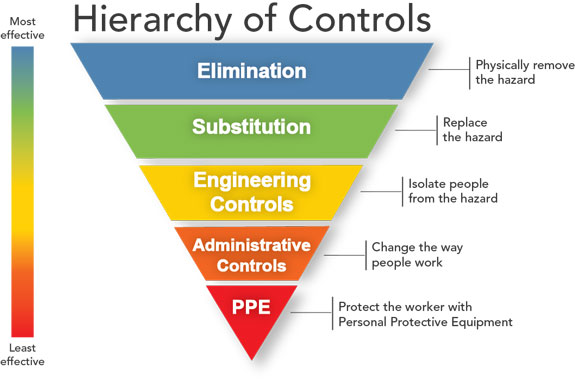

Not just table saw safety but safety in any guise, and I think some of the antics on you tube are even more worrying because to me it appears that the person is totally oblivious to the hazards they are exposing themselves to. Having worked in safety critcal enviroments the one thing we always said was that the only real safety control system is one where no human interaction is required and the process is automatic, put a human in the process and you add far to many excuses as to why it will fail at the critical moment.

As I said you cannot protect people from there own stupidity, the human race can be inherently stupid as demonstrated by this pandemic which has clearly highlighted this with the vast number of people just ignoring all covid precautions and acting like they are somehow immune, same attitude as the person who falls off a ladder by over stretching or losing some digits on a saw so really just let natural selection prevail.

nonsense… for someone who claims to have worked in a ‘safety is paramount’ industry, you should be aware that the goal is to reduce the likelihood of the hazard, or ideally remove the risk altogether (and thus protect the silly person not paying attention or working foolishly). As someone else has pointed out (apologies for not quoting their username), any employer would be a fool to not use this tech where possible in their operation. It is entirely analogous to the seatbelt and airbags in my car that I have, so far, not had use for.Cannot see the connection, what I am saying is you cannot protect someone from themselves if they do not have the right attitude, they are essentially an accident waiting to happen. No mater how much you try and make everything safe you have to accept that life is not risk free and it is your responsibility to remain unharmed and not expect someone else to remove the risk for you.

safety starts with the worker

You can see where it will end up, somebody will stick a finger into a saw to see if it is fitted with a safety device

Enter your email address to join: