Mikey R

Established Member

Hey all, sorry Ive not been on here much recently - since Ive started a new project I though I'd fix that and post a progress thread.

For those interested in such things, heres the spec:

5 strings 34" scale, 46mm nut, 17mm spacing at the bridge

24 fret maple fingerboard with side dots, no dots on fingerboard face

3 pc maple neck

MM style spoke nut dual action truss rod with carbon reinforcement rods

3 pc poplar body, painted finish

Chrome hardware, Schaller 2000 bridge, Gotoh small tuners

The shape is based in Leo Fenders class Jazz bass, slightly modified to make it a little more contemporary:

I bought the timber from the my usual place, John Boddys Timber. To get the haul home, I had to cut the boards down in the car park, when measuring up to glue up the blank I found I was a little too short! So with some head scratching I found if I arranged my template is just such a way I could just about fit it on, with a bit of an odd cut. Heres the body blank after jointing and in the clamps:

I made up a template for the router - using a 1/2 inch bit and a 26mm collar, the template needs to be around 6.5mm undersized:

This allowed me to start with a 30mm collar to take off the bulk of the waste, then come in with a 28mm and finally a 26mm collar.

Ive never seen this done in any photos, but I assumed theres no reason not to, so heres my T10 router mounted in the table with the collar. Theres about 3mm clearance under the ruler:

The body was rough cut with the jigsaw (really want a bandsaw!) then cleaned up on the router table:

The first pass was using a 30mm collar, so we're still 2mm over sized here. Some nasty tearout:

Taking 1mm passes at a time, I got a much cleaner result:

Burnt like crazy over the tricky bits though!

Then followed up with a roundover bit and a bit of carving:

For the forarm contour, I planed the bulk away with the smoothng plane, then finished up the roundover with sandpaper. On the belly contour, I used the drawknife, followed by Auriou rasp (DRIVEBY!) followed by the scraper to clean up, again adding back the roundover with sanpaper.

For those interested in such things, heres the spec:

5 strings 34" scale, 46mm nut, 17mm spacing at the bridge

24 fret maple fingerboard with side dots, no dots on fingerboard face

3 pc maple neck

MM style spoke nut dual action truss rod with carbon reinforcement rods

3 pc poplar body, painted finish

Chrome hardware, Schaller 2000 bridge, Gotoh small tuners

The shape is based in Leo Fenders class Jazz bass, slightly modified to make it a little more contemporary:

I bought the timber from the my usual place, John Boddys Timber. To get the haul home, I had to cut the boards down in the car park, when measuring up to glue up the blank I found I was a little too short! So with some head scratching I found if I arranged my template is just such a way I could just about fit it on, with a bit of an odd cut. Heres the body blank after jointing and in the clamps:

I made up a template for the router - using a 1/2 inch bit and a 26mm collar, the template needs to be around 6.5mm undersized:

This allowed me to start with a 30mm collar to take off the bulk of the waste, then come in with a 28mm and finally a 26mm collar.

Ive never seen this done in any photos, but I assumed theres no reason not to, so heres my T10 router mounted in the table with the collar. Theres about 3mm clearance under the ruler:

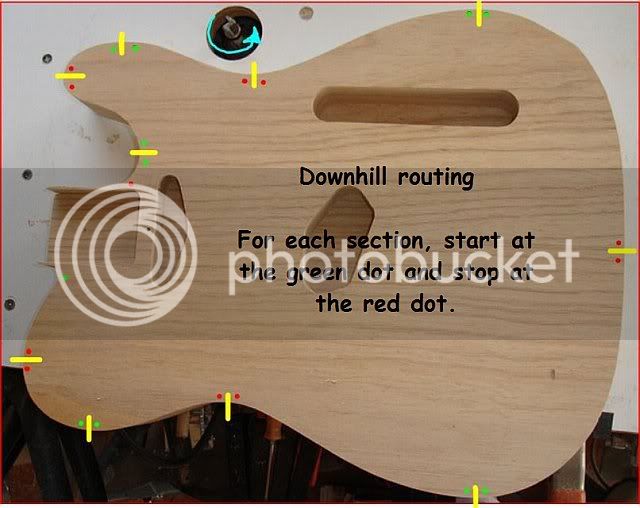

The body was rough cut with the jigsaw (really want a bandsaw!) then cleaned up on the router table:

The first pass was using a 30mm collar, so we're still 2mm over sized here. Some nasty tearout:

Taking 1mm passes at a time, I got a much cleaner result:

Burnt like crazy over the tricky bits though!

Then followed up with a roundover bit and a bit of carving:

For the forarm contour, I planed the bulk away with the smoothng plane, then finished up the roundover with sandpaper. On the belly contour, I used the drawknife, followed by Auriou rasp (DRIVEBY!) followed by the scraper to clean up, again adding back the roundover with sanpaper.