Bod

Established Member

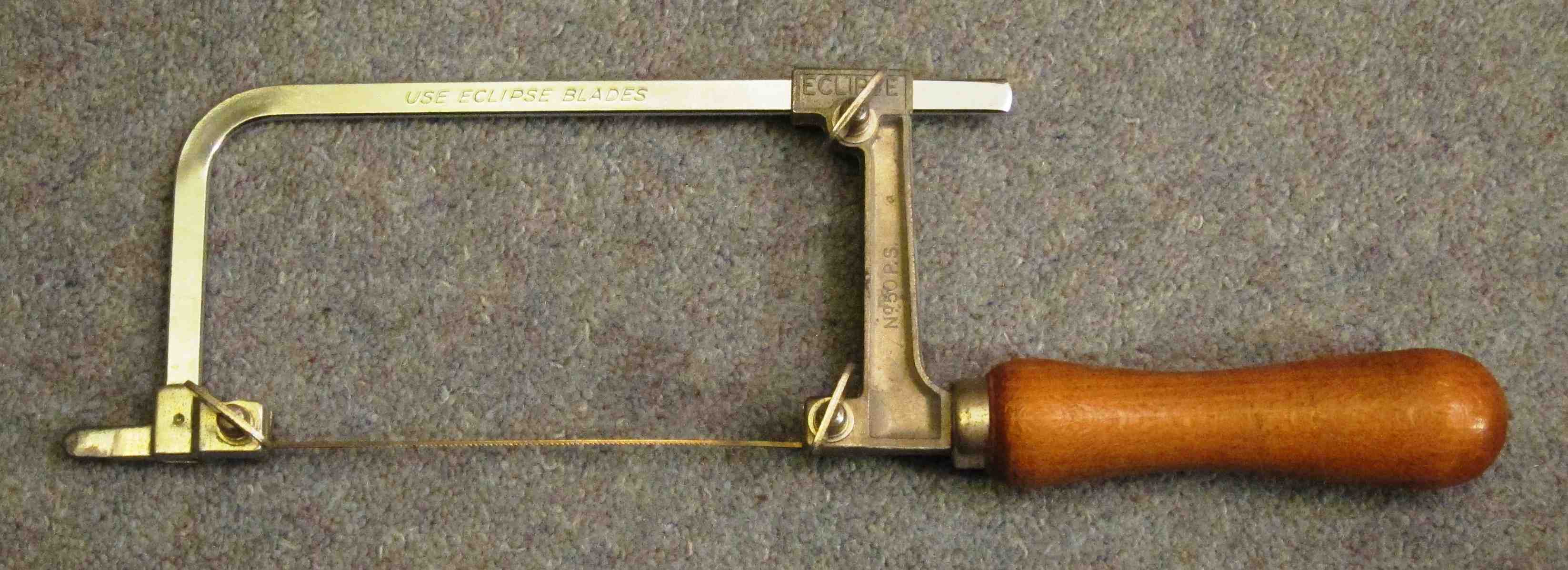

I've at long last acquired one of these, why I don't know!

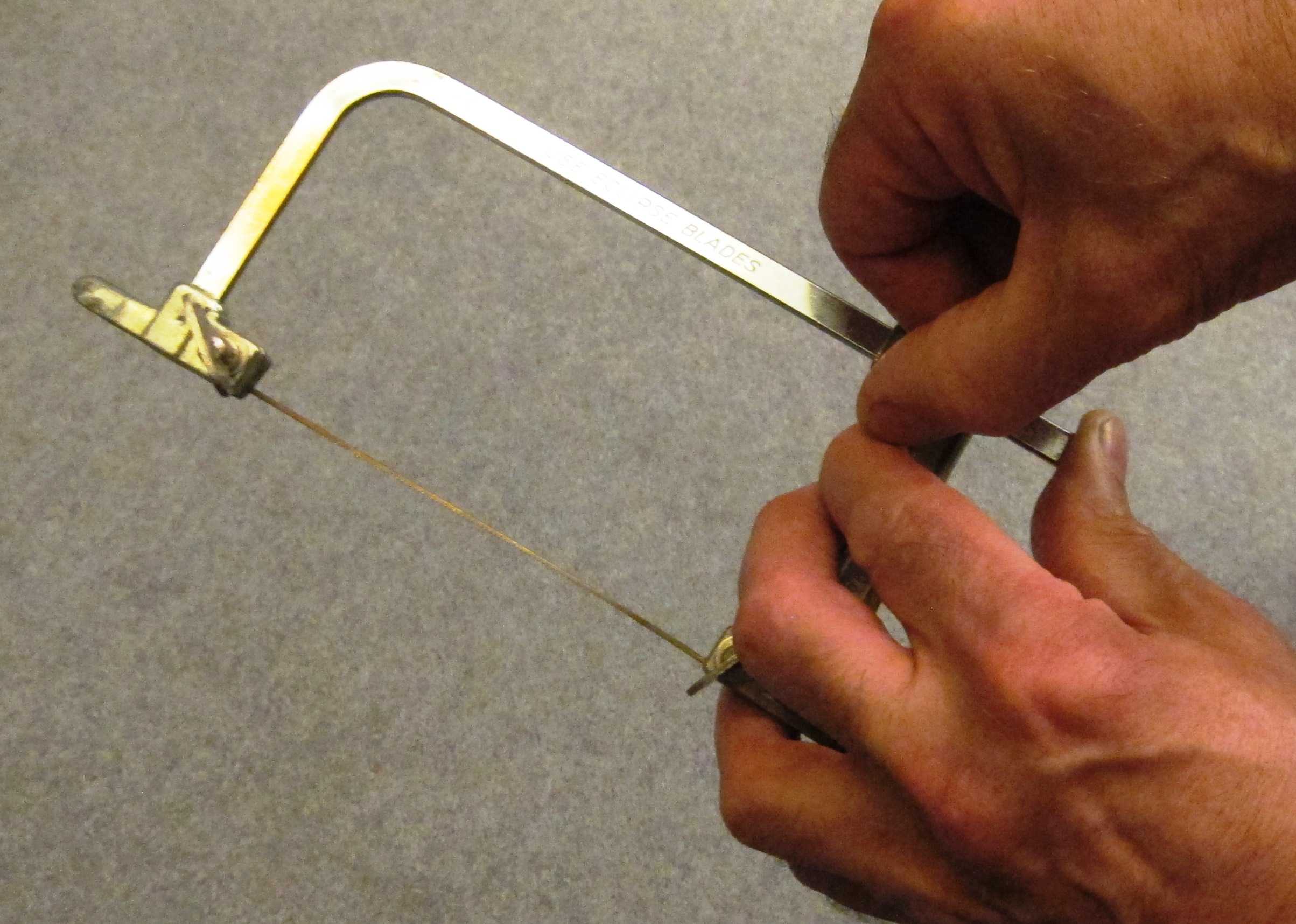

The question is. How do you tension the blade?

All of my books mention Coping/fret saws, with sprung frames, none mention the piecing saw.

Google seems to say it's a jewellers tool rather than a wood tool, no mention is made of what type of blade to use.

I've fitted a fret saw blade, but what tension I can get is by coping/fret saw standards pretty poor.

I feel this is a tool, best used to get a bit more life, from broken blades.

Bod

The question is. How do you tension the blade?

All of my books mention Coping/fret saws, with sprung frames, none mention the piecing saw.

Google seems to say it's a jewellers tool rather than a wood tool, no mention is made of what type of blade to use.

I've fitted a fret saw blade, but what tension I can get is by coping/fret saw standards pretty poor.

I feel this is a tool, best used to get a bit more life, from broken blades.

Bod