Scott

Established Member

- Joined

- 18 Oct 2004

- Messages

- 846

- Reaction score

- 0

For Mike and anyone else with a passing interest...

I fitted the Breakout Limiting Block to my DeWalt 712 SCMS this morning.

It's this item here:

http://www.dm-tools.co.uk/store/newsear ... ge=&issue=

The kit contains two plastic mouldings + two screws and two washers for fitting.

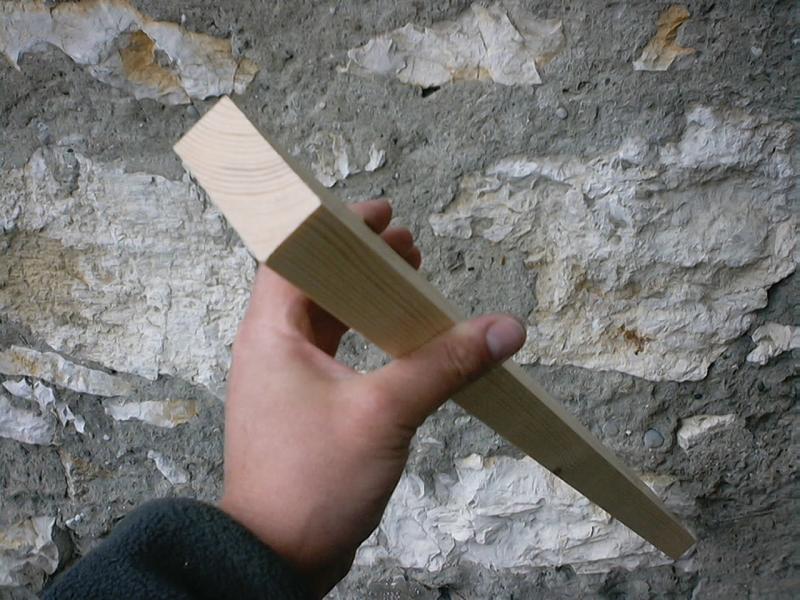

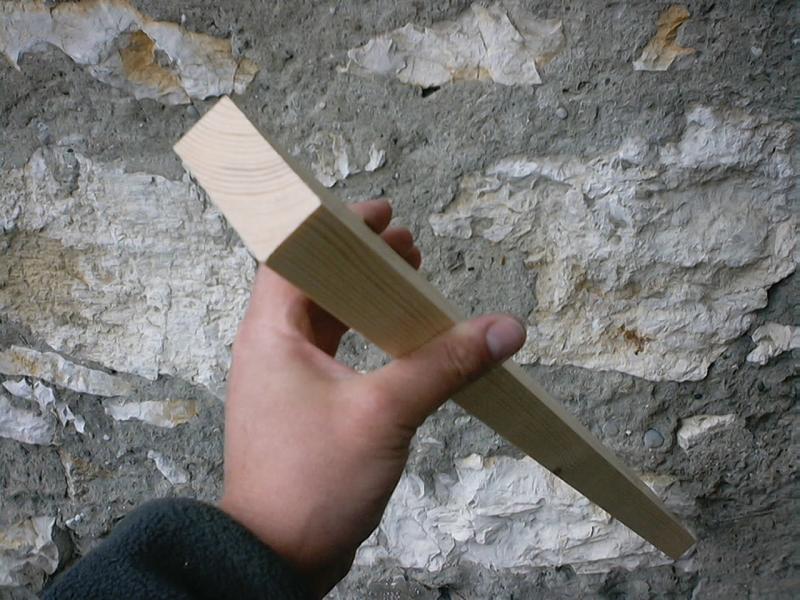

The block looks like this:

I did think that the plastic seemed a tad brittle for a thing of the kind but..

Unfortunately, for some reason, the mounting holes in the fence casting were not tapped so I had to get the M6 taps out :!: Easy enough but unexpected.

The screws are Torx/Flathead but the Allen key on the end of the onboard blade spanner fits them too. They don't need to be tight.

I cut a piece of pine with the 24T DeWalt blade (as supplied) before fitting the block:

and then cut it again after fitting the breakout limiting block and lining it up to the fence with a straightedge:

The plastic obviously wasn't too brittle!

It left a nice finish on pine straight off the saw with only tiny feathers on the cut edge. The only problem with these things is that they are only useful for one angle. Any other angle will cut into the plastic and destroy the "zero clearance".

My saw gets most use on zero bevel at 0 degrees and 45 degrees mitre so I'll cut the other block at 45 degrees and that'll do. I can't see myself making up whole sets of blocks for different angles etc but I guess they'll be OK for the bulk of my use.

What I did find is that the kerf in the plastic block now provides a perfect way of lining up the blade with the guage/pencil line for cutting as you can see from this:

I fitted the Breakout Limiting Block to my DeWalt 712 SCMS this morning.

It's this item here:

http://www.dm-tools.co.uk/store/newsear ... ge=&issue=

The kit contains two plastic mouldings + two screws and two washers for fitting.

The block looks like this:

I did think that the plastic seemed a tad brittle for a thing of the kind but..

Unfortunately, for some reason, the mounting holes in the fence casting were not tapped so I had to get the M6 taps out :!: Easy enough but unexpected.

The screws are Torx/Flathead but the Allen key on the end of the onboard blade spanner fits them too. They don't need to be tight.

I cut a piece of pine with the 24T DeWalt blade (as supplied) before fitting the block:

and then cut it again after fitting the breakout limiting block and lining it up to the fence with a straightedge:

The plastic obviously wasn't too brittle!

It left a nice finish on pine straight off the saw with only tiny feathers on the cut edge. The only problem with these things is that they are only useful for one angle. Any other angle will cut into the plastic and destroy the "zero clearance".

My saw gets most use on zero bevel at 0 degrees and 45 degrees mitre so I'll cut the other block at 45 degrees and that'll do. I can't see myself making up whole sets of blocks for different angles etc but I guess they'll be OK for the bulk of my use.

What I did find is that the kerf in the plastic block now provides a perfect way of lining up the blade with the guage/pencil line for cutting as you can see from this: