I`m putting my final touches on my dust extraction plan. My problem at the moment is going to be walking over to turn it on everytime I want to use a connected machine.

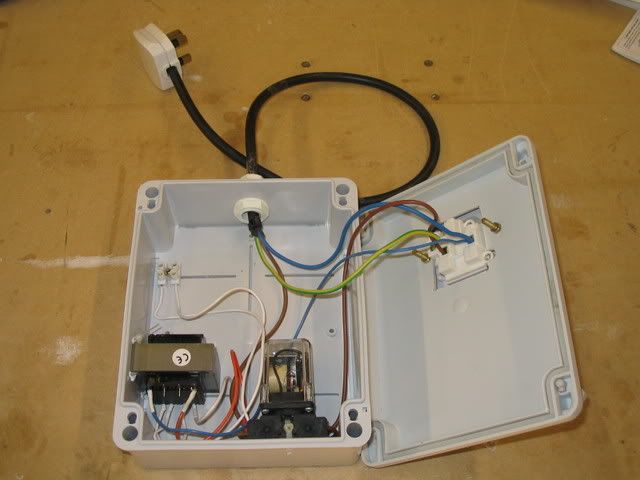

any solutions anyone know of? Ideally I`d like to have an automatic system..... A bit like my monitor and printer are automatically turned on by a "sensing" 4 way plug through with the computer base unit is connected.

So in an ideal world I`d like like a "special" plug in the shop that turns the extraction system on when it senses the tablesaw/router/bandsaw/planer etc have been turned on.

A "side note" problem to consider is that my extractor has a NVR switch............

any ideas welcome.....

Steve

any solutions anyone know of? Ideally I`d like to have an automatic system..... A bit like my monitor and printer are automatically turned on by a "sensing" 4 way plug through with the computer base unit is connected.

So in an ideal world I`d like like a "special" plug in the shop that turns the extraction system on when it senses the tablesaw/router/bandsaw/planer etc have been turned on.

A "side note" problem to consider is that my extractor has a NVR switch............

any ideas welcome.....

Steve