You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Do angled tenons mean poor glue surfaces?

- Thread starter fobos8

- Start date

Help Support UKworkshop.co.uk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Jacob

Pint of bass, porkpie, and packet of crisps please

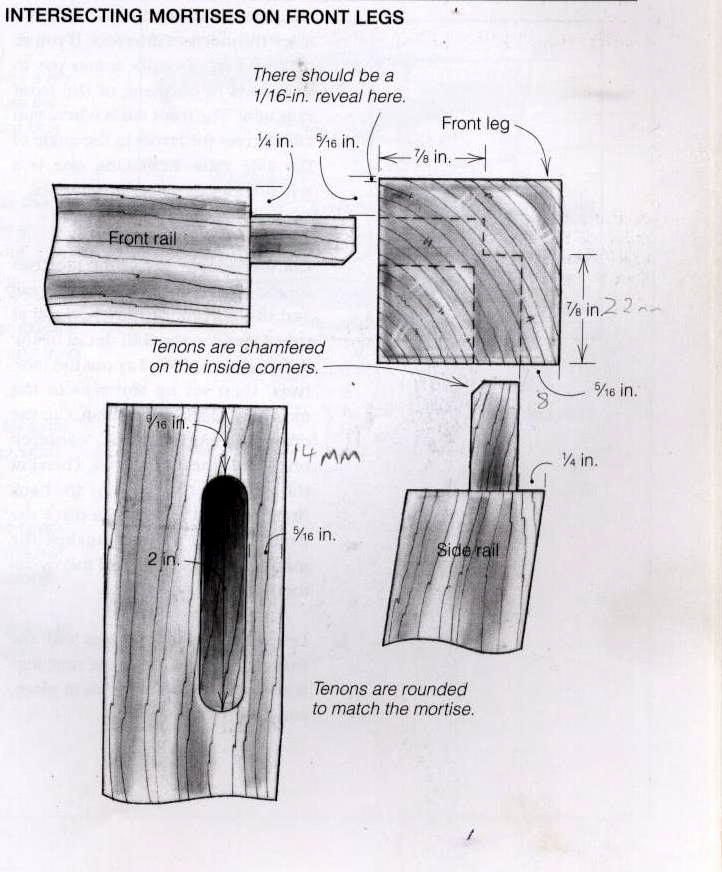

No that's really bad practice the tilted tenon in the bottom right picture. Don't do it! Just cos it's in a book doesn't mean it's right.

To be realistic - it'll do, but in the long term a straight grained tenon will do better.

To be realistic - it'll do, but in the long term a straight grained tenon will do better.

Steve Maskery

Established Member

The other thing you need to consider is the use of the loose tenon. Now I'm a big fan, but this is one example where you have to be really careful if you do decide to use one.

In order to maximise the length of the tenon in the leg, the tenon has to be placed as far to the outside as is conveniently possible. But the further out it is, the closer to the outside face of the rail it approached as you rout into the rail.

So this is one example where a trad tenon does have several advantages over a loose tenon.

S

In order to maximise the length of the tenon in the leg, the tenon has to be placed as far to the outside as is conveniently possible. But the further out it is, the closer to the outside face of the rail it approached as you rout into the rail.

So this is one example where a trad tenon does have several advantages over a loose tenon.

S

I agree with what your saying Steve.

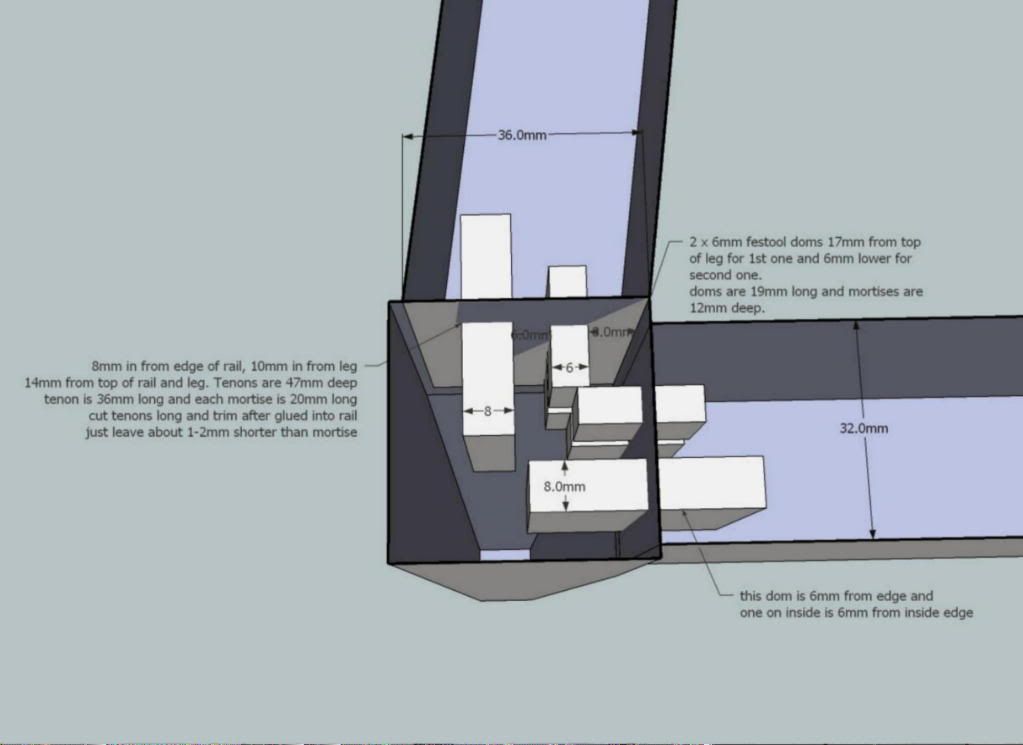

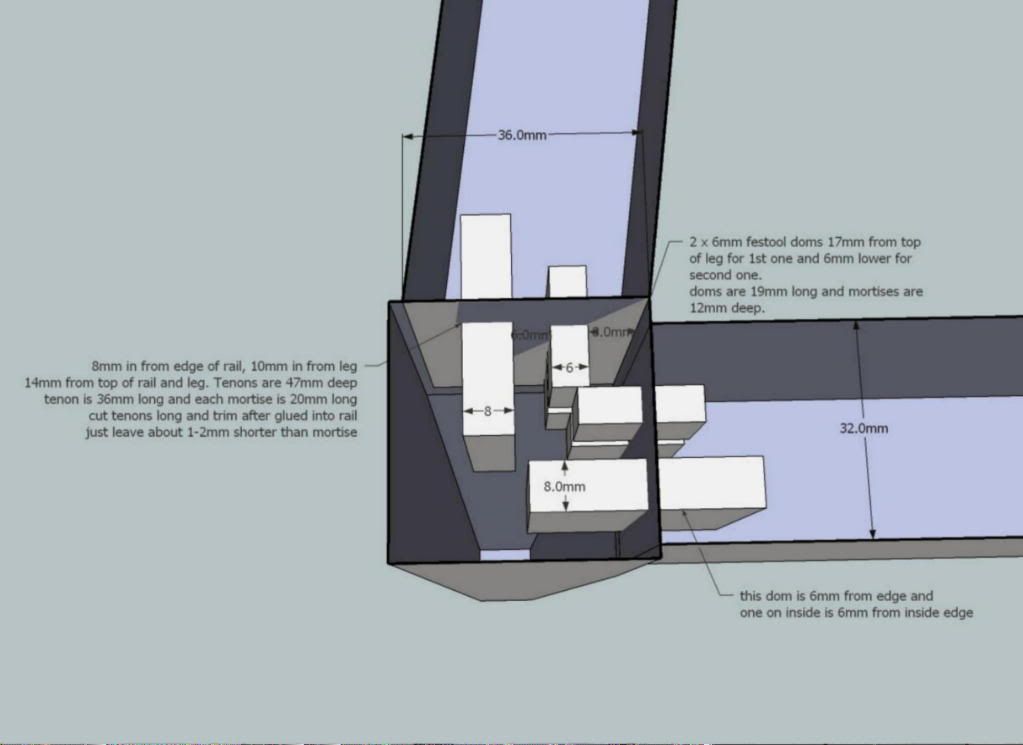

Attached is photo of how I intend to do it. I'll use my Domino but will make some of my own tenons. I reckon that by using two sets of tenons I can get a bigger glue area than the trad tenon in the Jeff Miller diagram. Also by using 8 and 6mm tenons I take out less volume of wood from the leg than in the Jeff Miller diagram.

IF YOU CLICK ON THE IMAGE IT WILL GET BIGGER.

regards, Andrew

Attached is photo of how I intend to do it. I'll use my Domino but will make some of my own tenons. I reckon that by using two sets of tenons I can get a bigger glue area than the trad tenon in the Jeff Miller diagram. Also by using 8 and 6mm tenons I take out less volume of wood from the leg than in the Jeff Miller diagram.

IF YOU CLICK ON THE IMAGE IT WILL GET BIGGER.

regards, Andrew

Jacob

Pint of bass, porkpie, and packet of crisps please

Completely insane. Don't do it!

Or to put it another way - why do you think your chair needs special and complicated details which you are unlikely to find anywhere in the whole history of chair making? Is there something you haven't told us? :shock:

Or to put it another way - why do you think your chair needs special and complicated details which you are unlikely to find anywhere in the whole history of chair making? Is there something you haven't told us? :shock:

Steve Maskery

Established Member

At the risk of sounding like the Jacob fan club, he does have a point.

The hardest part of this type of joint is arguably not the angled tenon, nor even the angled shoulders, but the angled mortice. It's not so bad if you have a hollow chisel mortiser, but it is very difficult if you use a router.

If you have a Domino then you have the best of both worlds. You can cut the shoulders cleanly after cutting the rail mortise. And you can use the angled fence to cut the angled mortice in the leg. That way you get the in-line grain just like in the olden days.

S

The hardest part of this type of joint is arguably not the angled tenon, nor even the angled shoulders, but the angled mortice. It's not so bad if you have a hollow chisel mortiser, but it is very difficult if you use a router.

If you have a Domino then you have the best of both worlds. You can cut the shoulders cleanly after cutting the rail mortise. And you can use the angled fence to cut the angled mortice in the leg. That way you get the in-line grain just like in the olden days.

S

Thanks for your input guys.

I don't see what is insane about the way I intend to do this joint though.

I have decided to us my Domino to do the joints. I just find it really easy. The downside of the current Domino is that the max mortise depth and so tenon length is 28mm. That's the reason for having 2 rows of tenons. I have used similar joints in tables and doors. They are easy to do - not complicated at all.

Steve I know you've used the Domino. Do you think that a single 28mm is a long enough tenon for this joint? I can make it about 45mm wide by making my own

Regards, Andrew

I don't see what is insane about the way I intend to do this joint though.

I have decided to us my Domino to do the joints. I just find it really easy. The downside of the current Domino is that the max mortise depth and so tenon length is 28mm. That's the reason for having 2 rows of tenons. I have used similar joints in tables and doors. They are easy to do - not complicated at all.

Steve I know you've used the Domino. Do you think that a single 28mm is a long enough tenon for this joint? I can make it about 45mm wide by making my own

Regards, Andrew

Jacob

Pint of bass, porkpie, and packet of crisps please

Well it's four tenons instead of the usual two deemed sufficient for chairs everywhere.fobos8":s2wvne7l said:....

I don't see what is insane about the way I intend to do this joint though......

Getting a pair accurately cut is much more than twice as difficult as just cutting one.

You are taking a lot of wood away from the top of the chair leg which could split vertically between the mortices.

You have introduced more cross grain weakness with two mortices' sides in the rail.

I think you are worrying too much about glue area. It's a structural joint, not just a connector; the tenons are load bearing. A single tenon properly done would be strong enough without glue if it was pinned instead. The glue is in place of a pin.

NB if this isn't just a one-off and you are seriously into chairs I wouldn't mess about with routers and loose tenons at all, I'd aim at doing it properly. A lot easier in the end.

xy mosian

Established Member

A lot of chairs have these rail/leg joints reinforced with a corner block. Are these going to be?

xy

xy

Steve Maskery

Established Member

fobos8":1ydu1kj0 said:Steve I know you've used the Domino. Do you think that a single 28mm is a long enough tenon for this joint? I can make it about 45mm wide by making my own

Yes. Many a chair leg is cut from ex-inch-and-a-half, so probably finishes at 34mm or so. Remember that te tenons will foul each other so you will have to mitre them.

Should be fine.

S

That's sorted then. Single loose tenon parallel to grain in rail and angled mortise in leg.

maybe even Jacob will approve it?

many thanks guys. It's been a very valuable knowledge exchange for me and I really appreciate your input

all the best, Andrew

maybe even Jacob will approve it?

many thanks guys. It's been a very valuable knowledge exchange for me and I really appreciate your input

all the best, Andrew

Jacob

Pint of bass, porkpie, and packet of crisps please

fobos8":1j6gk4vj said:That's sorted then. Single loose tenon parallel to grain in rail and angled mortise in leg.

maybe even Jacob will approve it?....

Similar threads

- Replies

- 44

- Views

- 2K

- Replies

- 1

- Views

- 709