You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Disc Sander - any recommendations?

- Thread starter Prizen

- Start date

Help Support UKworkshop.co.uk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Blackswanwood

Still Learning

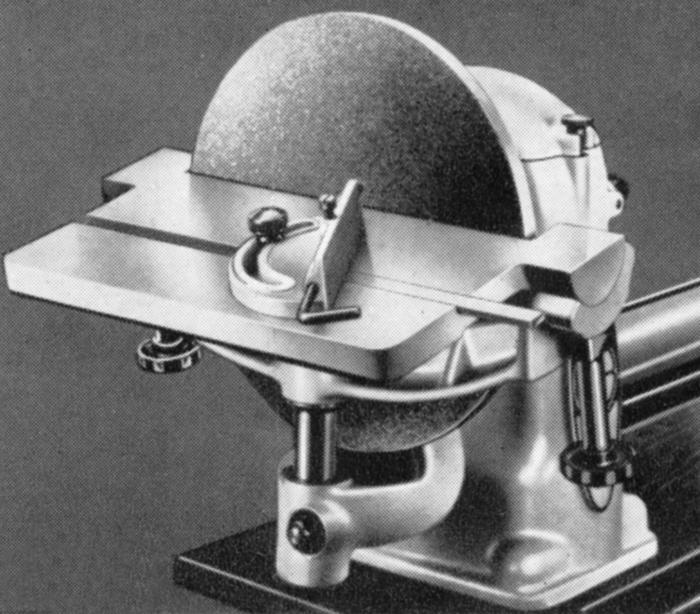

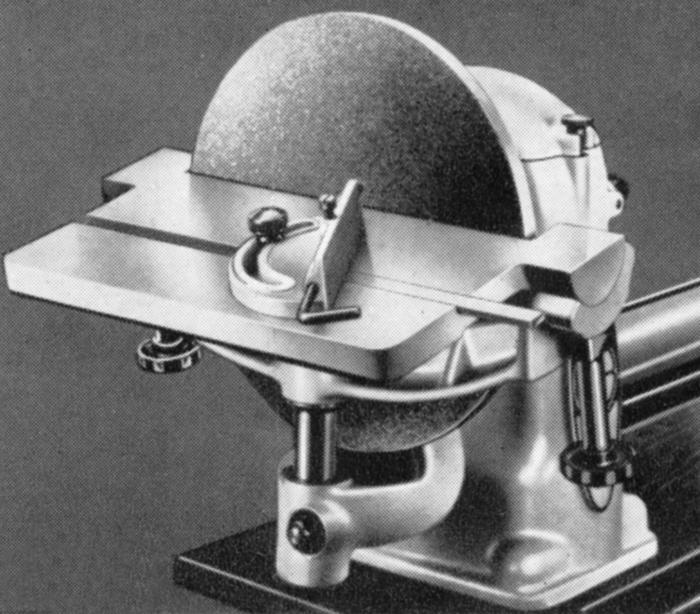

I have a Record DS300 which I picked up secondhand. After a bit of fettling it’s works like a dream. I mainly make boxes so work with smaller stock and tend not to need to move the table from 90 degrees as I can rely on the mitre fence and don’t need compound angles. A friend has an old 24” Wadkin which is an absolute monster ... it makes wood evaporate and takes about three days to stop rotating! It would be overkill for what I need though.

..I was going to get the cheaper belt / disc sander combination but I ended up getting a record 300mm Disc only sander.

I think this was the better choice as the actual working area of the disc is far more practical. (ie a 300 mm disc gives a far larger working area than a 150mm disc). I looked at a couple of makes but felt the Record with the cast iron table offered the best compromise on price v quality.

I have had it for a few years now and I have been quite happy with it.

I think this was the better choice as the actual working area of the disc is far more practical. (ie a 300 mm disc gives a far larger working area than a 150mm disc). I looked at a couple of makes but felt the Record with the cast iron table offered the best compromise on price v quality.

I have had it for a few years now and I have been quite happy with it.

I bought the Axminster 300 mm disc sander, used but in vgc from another forum member. It has been very satisfactory and includes table, fence and removable guard. It is only light hobby use of course, but very good for this purpose.

AJB Temple

Finely figured

I have a 300mm record. The first one was duff and was replaced. That seems to be typical Record - quiet a high problem rate.

Everyone takes the quadrant guard off. Obviously the cutting portion is the down stroke quadrant, but some people ( 8) find that they get very little lift in the first part of the upstroke quadrant, and so can work wider pieces.

The motor has no auto brake - you have to brake it manually using a friction brake on the top of the disk.

The Record is nowhere near as good as the one my ex father in law made for me years ago (great big motor) that I stupidly threw away in a house move.

If I were buying again I would without doubt look for a much larger disk used one. Even the bigger Axminster variant (not the 12" one). Depends what you are using it for of course.

Everyone takes the quadrant guard off. Obviously the cutting portion is the down stroke quadrant, but some people ( 8) find that they get very little lift in the first part of the upstroke quadrant, and so can work wider pieces.

The motor has no auto brake - you have to brake it manually using a friction brake on the top of the disk.

The Record is nowhere near as good as the one my ex father in law made for me years ago (great big motor) that I stupidly threw away in a house move.

If I were buying again I would without doubt look for a much larger disk used one. Even the bigger Axminster variant (not the 12" one). Depends what you are using it for of course.

transatlantic

Boom!

AJB Temple":ijdzst4p said:Everyone takes the quadrant guard off. Obviously the cutting portion is the down stroke quadrant, but some people ( 8) find that they get very little lift in the first part of the upstroke quadrant, and so can work wider pieces.

I've not used it to sand anything that big yet, but doing as you say, don't you find the difference in speed to be problematic?

I have the Record one, and it arrived in quite the state. The table mechanism had completely seized as there wasn't enough play in the holes for it to pivot freely, and so was just smacked in place at the factory. Took it all apart and did a little filling, and it's now ok.

Mitre guage is utterly useless, it's about 10deg off square. Record claim this is within tolerance as it's only a rough working tool. I may file it down one day to correct it, but haven't needed it so far.

Table is ground very very roughly. It seems flat enough, but yeah ... needs a bit of a sanding to things move along it smoothly.

One thing I am having trouble with is getting the abrasive discs to stick to the wheel properly. The machine came absolutely caked in grease, and I did give the whole thing a clean with IPA, but will have to give the wheel several more cleans I think. I'm also wondering if it's because the wheel is not smooth (again, rough grinding).

All in all though, I'm happy I have it as it's very useful.

..I always thought Record was a "better quality"m but I recently got their wet stone disc grinder which packed up after 30 mins due to the motor falling apart. (Returned for refund). Really disappointed as in general I did like Record stuff and was about to buy a bigger bandsaw. But after this experience I may look elsewhere.

Simply can't understand why they can't do a bit of QA on their own products rather than relying on their customers to do it for them?

Simply can't understand why they can't do a bit of QA on their own products rather than relying on their customers to do it for them?

Trevanion

Greatest Of All Time

I've got a Myford ML8 lathe (Or I did, it's currently in bits due for a bit of a restoration/spruce up  ) which has a 12" sanding plate and bed attachment that can be put on the outboard side.

) which has a 12" sanding plate and bed attachment that can be put on the outboard side.

It's less of a recommendation and more of an idea, if you've already got a lathe it would be pretty easy and cheap to knock up something to fit to a faceplate and some kind of makeshift bed in the banjo.

It's less of a recommendation and more of an idea, if you've already got a lathe it would be pretty easy and cheap to knock up something to fit to a faceplate and some kind of makeshift bed in the banjo.

Similar threads

- Replies

- 8

- Views

- 340

- Replies

- 3

- Views

- 163

- Replies

- 46

- Views

- 4K