Looking great. Is that a framing nailer I see in the box. I’ve been browsing for one myself the last couple of days but struggling to find a decent second hand one. They’re very pricey new if you’ve not already got batteries and a charger.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

DBT85s Workshop - Moved in and now time to fit it out

- Thread starter DBT85

- Start date

Help Support UKworkshop.co.uk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

DBT85

Established Member

Thanks chaps! Quieter day today as I have some grass to get mown and a wasps nest to deal with. Hopefully I'll get those soles bedded and strapped today though.

Yeah we got it new with the plan to sell it when I'm done. The hire shop we use has already expressed interest so we shall see. I got it from ITS for £440 and it was delivered less than 24 hours after ordering.gerard b":2dww5t6z said:Looking great. Is that a framing nailer I see in the box. I’ve been browsing for one myself the last couple of days but struggling to find a decent second hand one. They’re very pricey new if you’ve not already got batteries and a charger.

Lons

Established Member

You'll love it. One of the features I like is the anti jam lever. You'll occasionally get a jammed nail, happened a lot on the Paslode especially if using other brand nails, much less on the DeWalt but if it does it's just a flick of the lever to clear.DBT85":2chvaacc said:Yeah we got it new with the plan to sell it when I'm done. The hire shop we use has already expressed interest so we shall see. I got it from ITS for £440 and it was delivered less than 24 hours after ordering.gerard b":2chvaacc said:Looking great. Is that a framing nailer I see in the box. I’ve been browsing for one myself the last couple of days but struggling to find a decent second hand one. They’re very pricey new if you’ve not already got batteries and a charger.

Strange they've given you a universal case as the proper case is much better, unless it's been changed.

I was very lucky as I was offered one of the first evaluation models to review and allowed to keep it

DBT85

Established Member

Very nice! This is just the one it comes with I think when you get it with the charger and 2 batteries. Maybe not. It'll be useful for someone that actually wants the second fix gun too.Lons":3vqbkugk said:You'll love it. One of the features I like is the anti jam lever. You'll occasionally get a jammed nail, happened a lot on the Paslode especially if using other brand nails, much less on the DeWalt but if it does it's just a flick of the lever to clear.DBT85":3vqbkugk said:Yeah we got it new with the plan to sell it when I'm done. The hire shop we use has already expressed interest so we shall see. I got it from ITS for £440 and it was delivered less than 24 hours after ordering.gerard b":3vqbkugk said:Looking great. Is that a framing nailer I see in the box. I’ve been browsing for one myself the last couple of days but struggling to find a decent second hand one. They’re very pricey new if you’ve not already got batteries and a charger.

Strange they've given you a universal case as the proper case is much better, unless it's been changed.

I was very lucky as I was offered one of the first evaluation models to review and allowed to keep it

DBT85":11j8wyfz said:Thanks chaps! Quieter day today as I have some grass to get mown and a wasps nest to deal with. Hopefully I'll get those soles bedded and strapped today though.Yeah we got it new with the plan to sell it when I'm done. The hire shop we use has already expressed interest so we shall see. I got it from ITS for £440 and it was delivered less than 24 hours after ordering.gerard b":11j8wyfz said:Looking great. Is that a framing nailer I see in the box. I’ve been browsing for one myself the last couple of days but struggling to find a decent second hand one. They’re very pricey new if you’ve not already got batteries and a charger.

What model is it, DCN692P2? I'm in Ireland and the best price I can see for one new is 685euro (around £610), that's with two 5Ah batteries and the charger.

DBT85

Established Member

gerard b":5yuz7xgo said:What model is it, DCN692P2? I'm in Ireland and the best price I can see for one new is 685euro (around £610), that's with two 5Ah batteries and the charger.

Yep that's the one. ITS won't ship to ROI but FFX do and they want £440 for it. ITS only actually charged us £432. I think FFX want about £30 for delivery to ROI?

Or you can wait 2 months and buy this one from me :lol:

Box, 2x 5ah batteries and the charger.

Lol, I hope to be finished with it myself by then. That is a super price at FFX but they are saying delivery by 1st July, 3 weeks, I'm not waiting that long. Have you tried it out yet? Let us know what you think.

gerard b":11tuh4x4 said:Lol, I hope to be finished with it myself by then. That is a super price at FFX but they are saying delivery by 1st July, 3 weeks, I'm not waiting that long. Have you tried it out yet? Let us know what you think.

They're brilliant. A 4ah battery nearly lasts all day when nailing roofing battens all day so for normal work they'll easily last a day. They're heavy, you know if you've been swinging one about all day. I've had one jammed nail the other day that took me undoing two Allen screws to get it out but it was literally 5 mins downtime. I must have fired roughly 15k nails with mine and apart from that one nail it's been perfect. I've used all brands of nails too even the cheap ones work fine.

DBT85

Established Member

Well the weather here is rubbish today, I just about managed to sort the grass as it had been many weeks and much of it is field grass not lawn grass. The wasps nest seems to have been dealt with also, hurrah.

Before I can get chopping anything up I need another sawhorse. I have one kicking around for some reason so I'll make it a sibling and I can use some of the formwork timbers as a benchtop for my mitre saw. I also need to finish tinkering with the plans and be sure of my dimensions! The plates will naturally be cut to the size required on my actual build, but I don't want my studs too long as otherwise I'll end up over the 2.5m eaves height rule.

FFX were just one of a few places that had them. try https://www.powertoolworld.co.uk/dewalt ... x-batt-5ah

Another option might be the Hikoki one. It's also battery only but it makes its own compressed air to help drive them home. The quick look I had at a video last night it did a good job and buried the 90mm ring shanks while the dewalt they had was sinking them flush.

Before I can get chopping anything up I need another sawhorse. I have one kicking around for some reason so I'll make it a sibling and I can use some of the formwork timbers as a benchtop for my mitre saw. I also need to finish tinkering with the plans and be sure of my dimensions! The plates will naturally be cut to the size required on my actual build, but I don't want my studs too long as otherwise I'll end up over the 2.5m eaves height rule.

I am as yet without nails so its not done anything yet.gerard b":2gjtsg3p said:Lol, I hope to be finished with it myself by then. That is a super price at FFX but they are saying delivery by 1st July, 3 weeks, I'm not waiting that long. Have you tried it out yet? Let us know what you think.

FFX were just one of a few places that had them. try https://www.powertoolworld.co.uk/dewalt ... x-batt-5ah

Another option might be the Hikoki one. It's also battery only but it makes its own compressed air to help drive them home. The quick look I had at a video last night it did a good job and buried the 90mm ring shanks while the dewalt they had was sinking them flush.

DBT85

Established Member

I really like Fusion, but how can it be that Sketchup has a better bloody measure tool than it for this purpose. Fortunately I've calculated it all anyway but it would be nice to just be able to click a point and it to measure a distance on the same plane. Eugh.

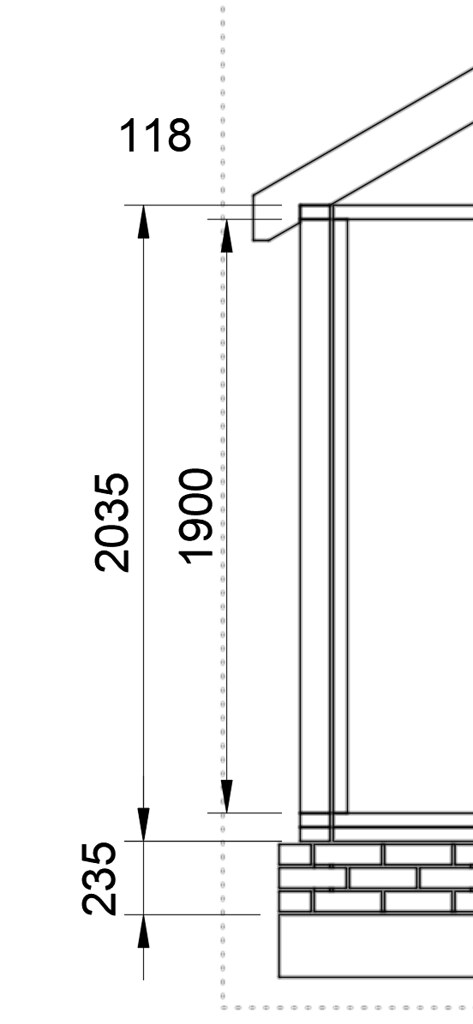

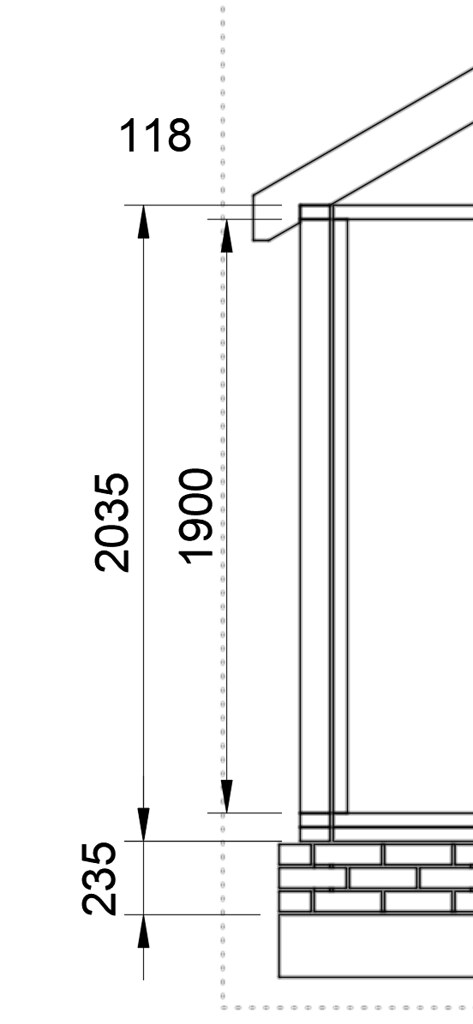

Stud lengths will be 1900mm.

This allows for the 235mm plinth + bedding mortar under the DPC, 118mm from the top of the top plate to the top of the rafter and an overall 2035mm frame height based on top plate, sole plate and other sole plate.

That brings the top of my rafters up to 2388mm, plus 50mm for the slightly exposed slab (I'll actually need to lower the far corner a little to do that so there is wiggle room).

So 2438mm, plus battens and tiles should being me in under the 2.5m eaves height. My calcs are based on the face of the stud and not the face of the cladding, which would actually bring the intersection of top of roof and wall down a little further.

Mike why am I wrong.

Stud lengths will be 1900mm.

This allows for the 235mm plinth + bedding mortar under the DPC, 118mm from the top of the top plate to the top of the rafter and an overall 2035mm frame height based on top plate, sole plate and other sole plate.

That brings the top of my rafters up to 2388mm, plus 50mm for the slightly exposed slab (I'll actually need to lower the far corner a little to do that so there is wiggle room).

So 2438mm, plus battens and tiles should being me in under the 2.5m eaves height. My calcs are based on the face of the stud and not the face of the cladding, which would actually bring the intersection of top of roof and wall down a little further.

Mike why am I wrong.

MikeG.

Established Member

DBT85":2k81n54j said:........Mike why am I wrong.........

Relying on your figures (ie without drawing it myself) I can't see anything wrong there.

For the sake of other people following along, the eaves height in use in Planning isn't the edge of the roof, but the notional point of intersection between the plane of the wall and the top of the roof covering. In other words, if someone came along with a giant trimming router and trimmed the edge of the roof off flush with the face of the wall, the eaves height (in planning terms) would be the top edge of the resulting vertical face.

Well I went for it and bought from power tool world, should have it mid next week hopefully.

Anyway sorry for hijacking your thread, concrete was poured today on my own build, I'll post a photo on the thread i started for mine. Thanks again.

Anyway sorry for hijacking your thread, concrete was poured today on my own build, I'll post a photo on the thread i started for mine. Thanks again.

DBT85

Established Member

No problem Gerard! I shall have a look see at your thread.

Anyway, an easier day today as I said, lawns mowed, numbers checked, back and knees given a slightly easier time.

Saw bench made up from formwork, work support added and the 6 pieces I need for bedding onto the mortar are cut, strap housings routed out and it all treated with cut end protector. I even cut one of the sole plates.

Naturally it took longer to find my safety glasses than it did to actually route out the housings.

Tomorrow morning I'll cut some folding wedges (I wonder if I can use the ones from making up the stakes?), nail the DPC onto the bottom of these and get some mortar made up to get them bedded down.

Video of the brickwork hasn't even been started yet but I'll get there!

Anyway, an easier day today as I said, lawns mowed, numbers checked, back and knees given a slightly easier time.

Saw bench made up from formwork, work support added and the 6 pieces I need for bedding onto the mortar are cut, strap housings routed out and it all treated with cut end protector. I even cut one of the sole plates.

Naturally it took longer to find my safety glasses than it did to actually route out the housings.

Tomorrow morning I'll cut some folding wedges (I wonder if I can use the ones from making up the stakes?), nail the DPC onto the bottom of these and get some mortar made up to get them bedded down.

Video of the brickwork hasn't even been started yet but I'll get there!

Forgive me if youve covered it already, but with the 4" with sole plate leaving the 2" or so of brick sticking out in the elements, wont water sit on this and eventually cause damp issues?

As even with 1" stud work and cladding the brick edge will still stick out? Unless yor classing 2" thick?

As even with 1" stud work and cladding the brick edge will still stick out? Unless yor classing 2" thick?

DBT85

Established Member

I realise I may have to redo those plates that cover the door end and it's opposite. I've not half lapped them to the sides and the actual sole plate that will sit on it will be about the same length as those plates so there is no overlap like there will be on the long sides.

Am I worrying about nothing?

The bottom FE board kicks out slightly to take its leading edge beyond the edge of the brickwork.

As seen on Mikes

Am I worrying about nothing?

No problem at all!Fil":uds36lim said:Forgive me if youve covered it already, but with the 4" with sole plate leaving the 2" or so of brick sticking out in the elements, wont water sit on this and eventually cause damp issues?

As even with 1" stud work and cladding the brick edge will still stick out? Unless yor classing 2" thick?

The bottom FE board kicks out slightly to take its leading edge beyond the edge of the brickwork.

As seen on Mikes

DBT85

Established Member

Mike, on this subject..

I realise I may have to redo those plates that cover the door end and it's opposite. I've not half lapped them to the sides and the actual sole plate that will sit on it will be about the same length as those plates so there is no overlap like there will be on the long sides.

Am I worrying about nothing?

I realise I may have to redo those plates that cover the door end and it's opposite. I've not half lapped them to the sides and the actual sole plate that will sit on it will be about the same length as those plates so there is no overlap like there will be on the long sides.

Am I worrying about nothing?

Lons

Established Member

DBT85":3e8nyke2 said:Another option might be the Hikoki one. It's also battery only but it makes its own compressed air to help drive them home. The quick look I had at a video last night it did a good job and buried the 90mm ring shanks while the dewalt they had was sinking them flush.

My DeWalt easily sinks the nail heads so they might have had the adjustment pressure knob on the nose turned down, it's a useful feature. My gun is only single speed so I don't know what advantage the newer 2 speed gun has.

Good point about the box re a second fix gun, hadn't thought about that but makes sense as you can buy them as a set so might have standardised the box. I have that box as well as when I was given the gun the lad said they didn't yet have a purpose made box and they sent that on to me later.

MikeG.

Established Member

DBT85":1prmojxg said:......Am I worrying about nothing?

Yep, relax. There are no forces on the walls pushing them apart at the bottom. The force the half-lap resists here is twisting, and with the weight of the workshop on them they will stay exactly where they were put. Just make sure you get a fixing in low down between the end studs of the end frames and the long-side frames. Bear in mind that I didn't have the first plate (I did when I built the house, but not the workshop), and that the panels struggle to have a half-lapped corner plate.

The other slight advantage of having a half lap at the corners is that the lower plates will be less inclined to get out of position as you manhandle the big frames on top of them. For this reason you might consider taking a bit of strapping and fixing it around the corners on the vertical outside faces of the plates, tying them together. You can remove this later if it's in the way, or leave it if it isn't.

Similar threads

- Replies

- 13

- Views

- 938