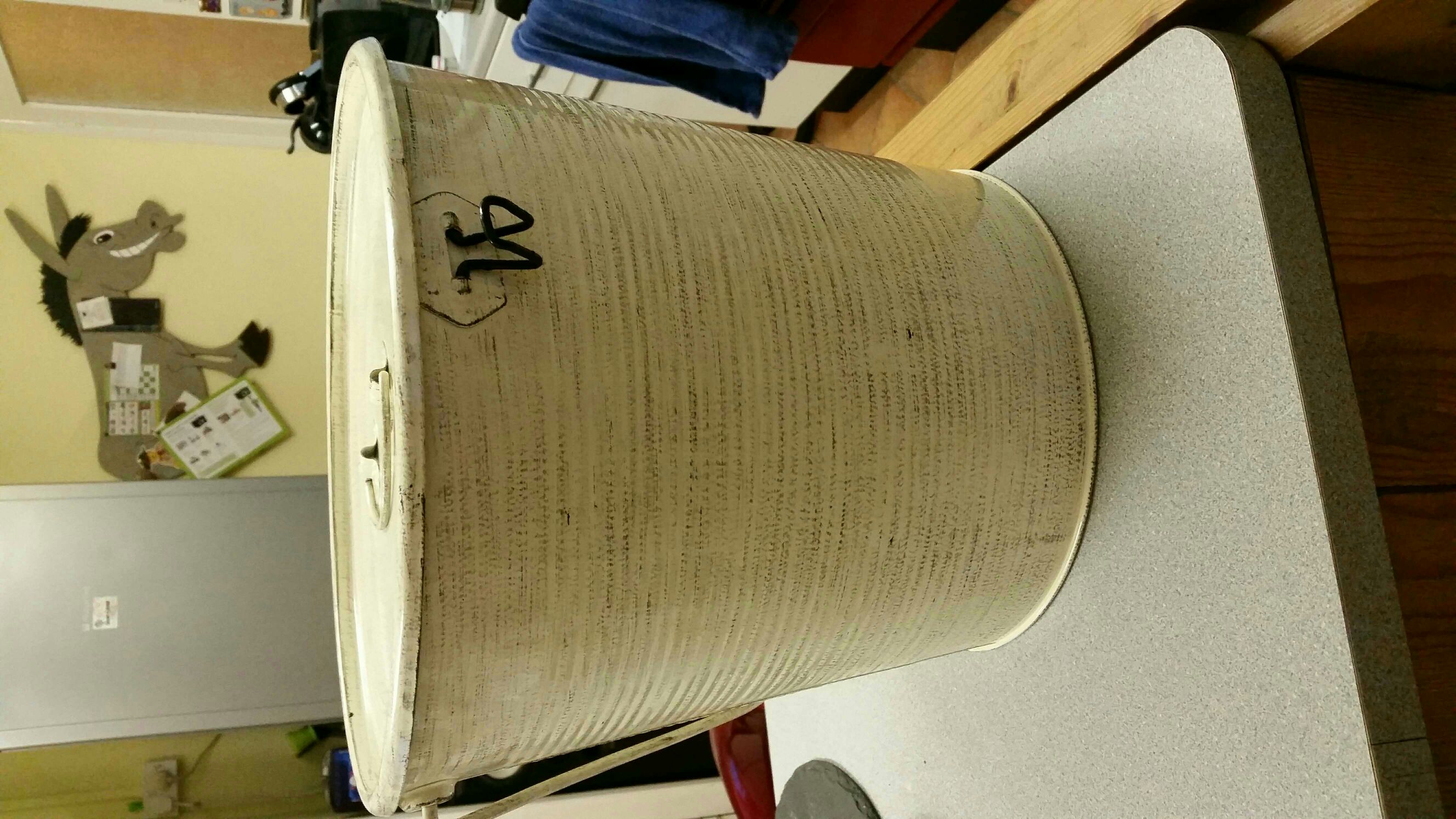

Guys I'm after some advice please. I've been playing around trying to get my cyclone to work and am still a bit unsure what might be going wrong. I've got the hoover connected up to a bucket but it still seems to be letting quite a lot of fine dust through. Any ideas what could be causing it ?

My old workmate came out and showed me his festool vac that automatically shakes the filter at a desired interval. I'm hoping I can get my current setup to work though.

Cheers

Coley

Sent from my SM-G900F using Tapatalk

Edit- pics added

My old workmate came out and showed me his festool vac that automatically shakes the filter at a desired interval. I'm hoping I can get my current setup to work though.

Cheers

Coley

Sent from my SM-G900F using Tapatalk

Edit- pics added