phillimp

Member

Hi All,

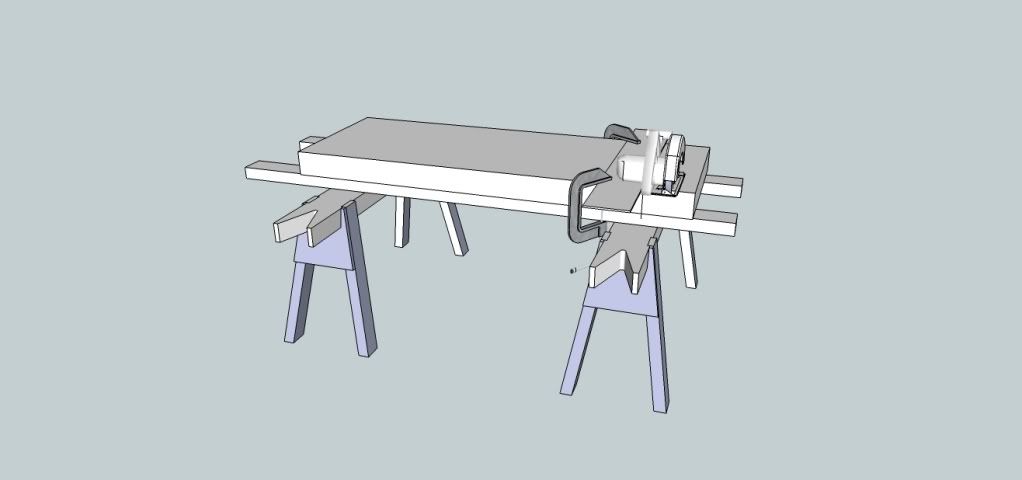

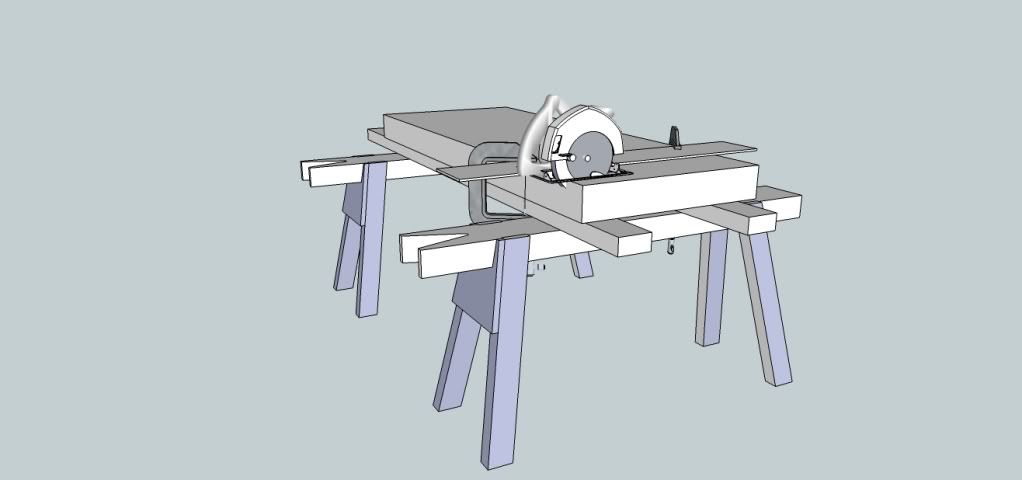

Any advice for the best tool to make a good clean cut through 4 inch thick ash (width is 24 inches)? This is for the top of a workbench that I need to square off to length.

Thanks, Paul

Any advice for the best tool to make a good clean cut through 4 inch thick ash (width is 24 inches)? This is for the top of a workbench that I need to square off to length.

Thanks, Paul