syntec4

Established Member

I own a pretty cheap and nasty Performance Power table saw.

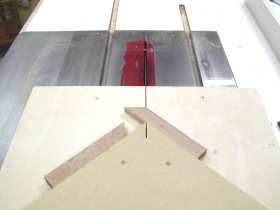

It is quite powerful and does most things I need it for, apart from cross cutting. The Mitre fence that is supplied with it is terrible. You simply cannot make a square cut with it. It wobbles around so much, it can make a huge difference to the cut. So I decide that I should try to fix it.

I made a cross cut sled out of MDF etc and you can have a look here to read about it.

http://homepage.ntlworld.com/lee_harrison944/Table saw Slide/index.htm

let me know what you think :wink:

I can now cross cut dead square upto 2' stock which is plenty for anything i might be doing. It looks pretty basic and it is. but it improves the performance of the saw no end. It was almost unusable before. I think I spent about £7 all in.

I'll start saving up for something decent after I get my new bandsaw, and planes, chisels...............

Cheers.

Lee.

It is quite powerful and does most things I need it for, apart from cross cutting. The Mitre fence that is supplied with it is terrible. You simply cannot make a square cut with it. It wobbles around so much, it can make a huge difference to the cut. So I decide that I should try to fix it.

I made a cross cut sled out of MDF etc and you can have a look here to read about it.

http://homepage.ntlworld.com/lee_harrison944/Table saw Slide/index.htm

let me know what you think :wink:

I can now cross cut dead square upto 2' stock which is plenty for anything i might be doing. It looks pretty basic and it is. but it improves the performance of the saw no end. It was almost unusable before. I think I spent about £7 all in.

I'll start saving up for something decent after I get my new bandsaw, and planes, chisels...............

Cheers.

Lee.