You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Clock

- Thread starter Harbo

- Start date

Help Support UKworkshop.co.uk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

jimi43

Established Member

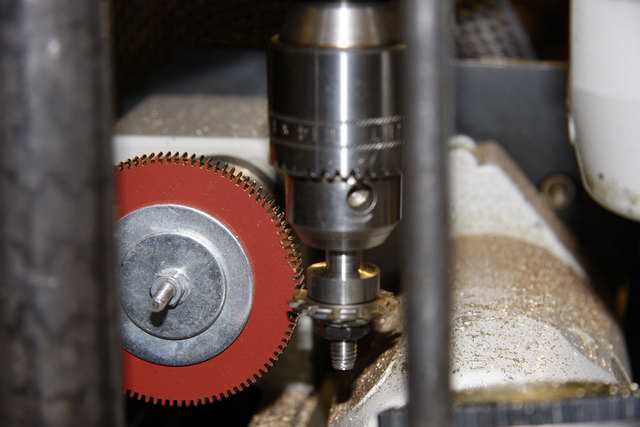

Hey Rod....still using the faithful Unimat 3 I see!

That use of a dial gauge is neat! I haven't had to do any super accurate stuff yet but when I do I think I will be using that idea...forgot all about my basic metalworking some time ago but I am sure they didn't teach me that one!

I was going to fit a little DRO or some of those iGauging things but that's far easier!

Cheers mate

Jim

That use of a dial gauge is neat! I haven't had to do any super accurate stuff yet but when I do I think I will be using that idea...forgot all about my basic metalworking some time ago but I am sure they didn't teach me that one!

I was going to fit a little DRO or some of those iGauging things but that's far easier!

Cheers mate

Jim

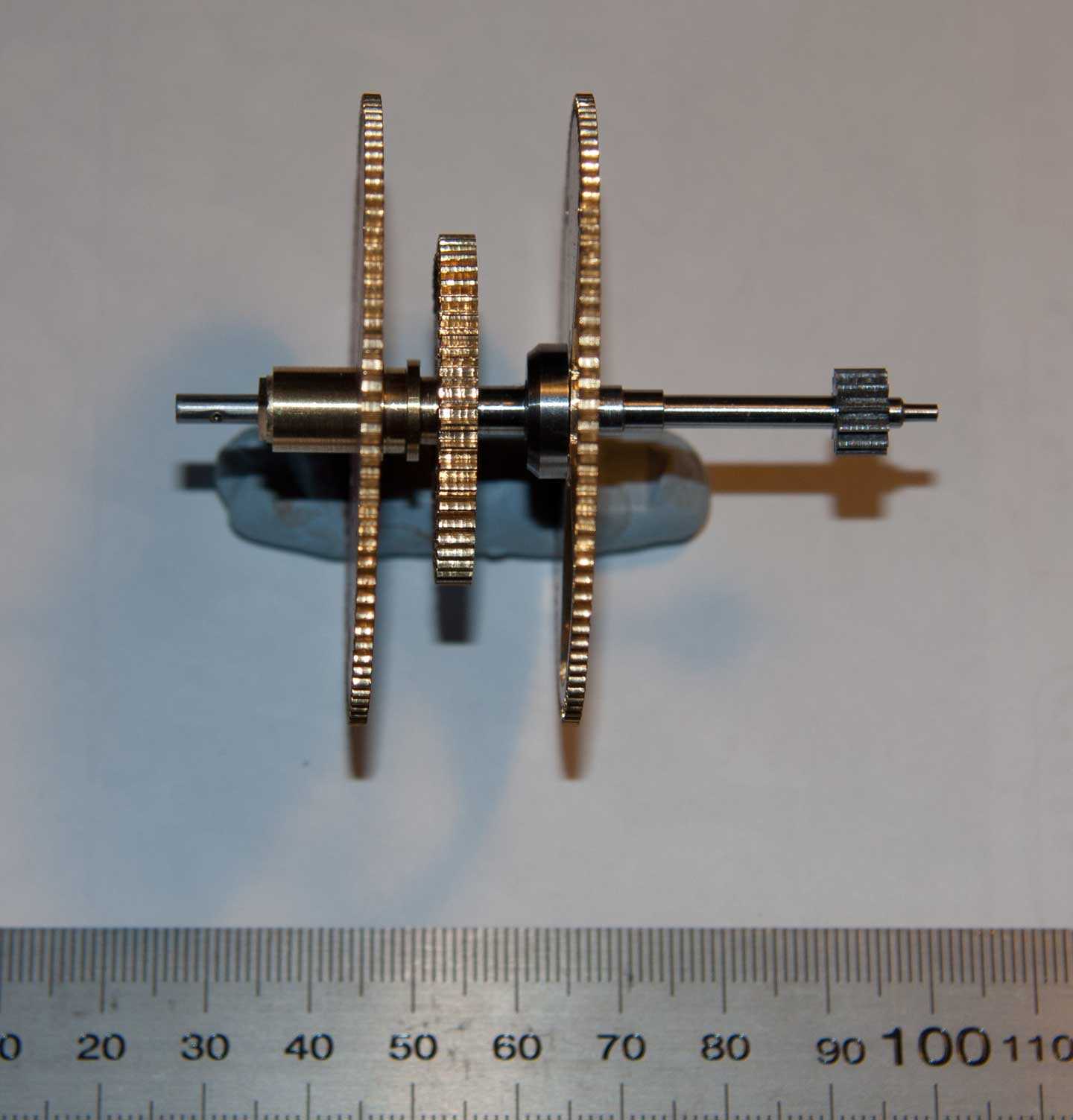

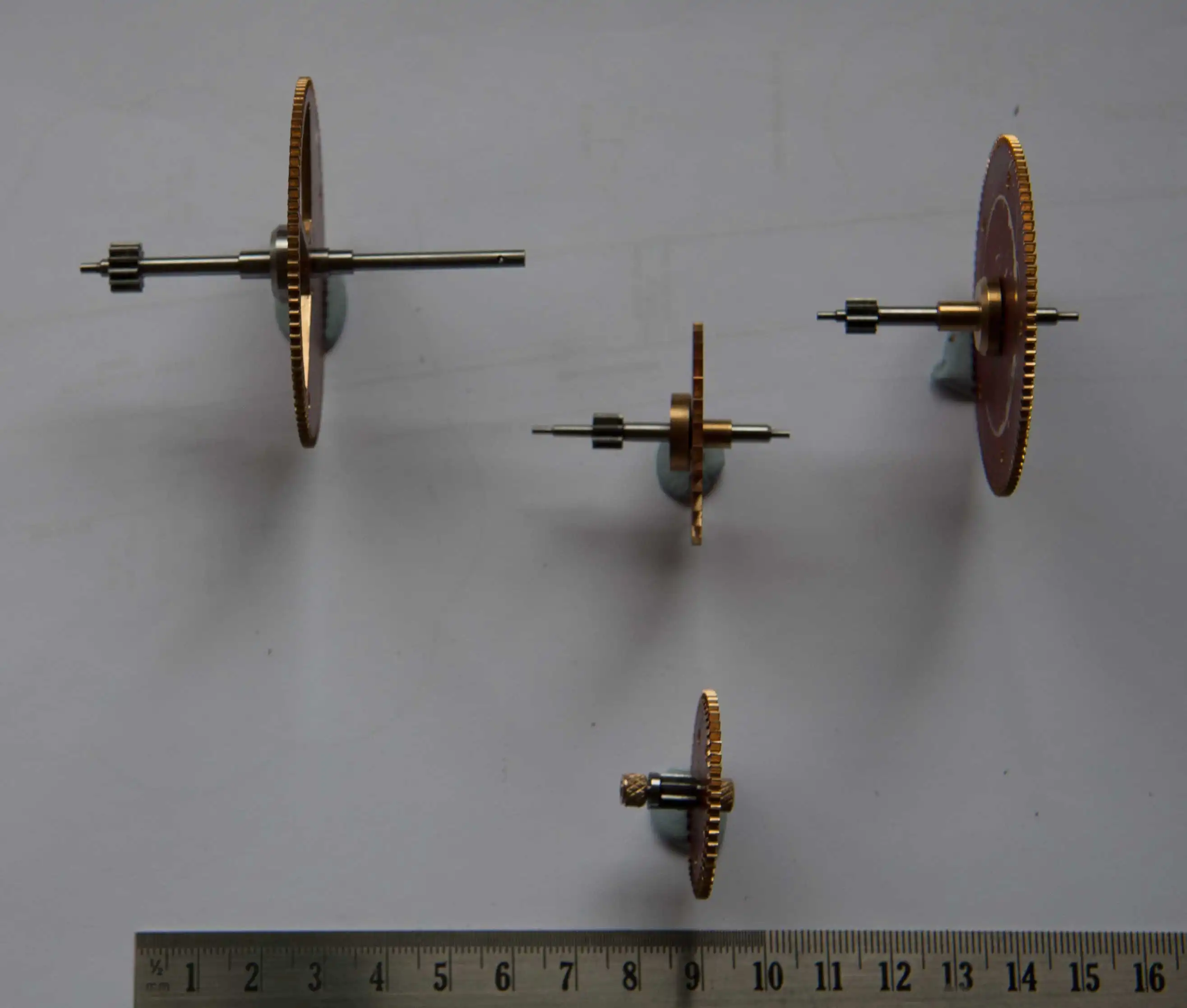

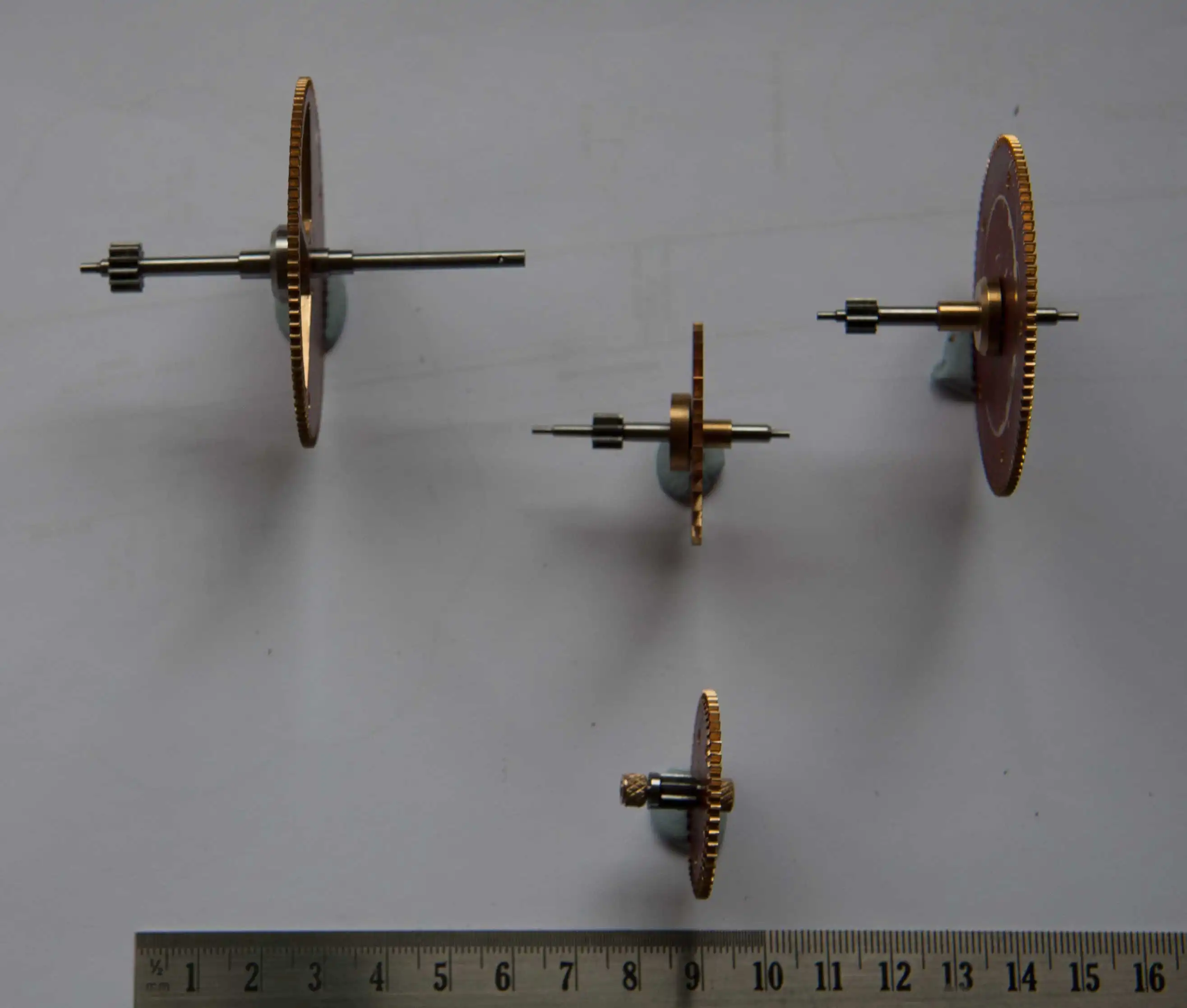

Dave - its cutting pinions - I'll post some more pics. And actually clock tolerances are not that high they have to have a bit of slack to work without too much friction?

Jim - Yes still using the Unimat but would love to upgrade (I keep looking at Cowells but they go for stupid prices?). I 've looked DRO but don't think any are small enough to work with the Uni?

My friend and neighbour has a Myford and a Centec 2B Mill which I can use for bigger stuff.

Rod

Jim - Yes still using the Unimat but would love to upgrade (I keep looking at Cowells but they go for stupid prices?). I 've looked DRO but don't think any are small enough to work with the Uni?

My friend and neighbour has a Myford and a Centec 2B Mill which I can use for bigger stuff.

Rod

£19.99

Respirator Mask,Safety Dust Face Cover,Dust Face Cover Paint Face Cover,Gas Mask With Filter,For Paint,Dust And Formaldehyde,Sanding,Polishing,Spraying And Other Work

ShenZHEN CIRY MINGYANG LITIAN ELECTRONIC ECOMMERCE

£24.99

Facemoon Reusable Masks,Safety Masks,Dual Filter Masks, Paint, Dust, Epoxy Resin, Construction, Welding, Sanding, Woodworking, Chemical Reusable Gas Masks

ShenZHEN CIRY MINGYANG LITIAN ELECTRONIC ECOMMERCE

£12.50 (£1,250.00 / kg)

£14.45 (£1,445.00 / kg)

JSP M632 FFP3moulded Disposable Dustmask (Box of 10) One Size suitable for Construction, DIY, Industrial, Sanding, dust protection 99 Percent particle filtration Conforms and Complies to EN 149

Amazon.co.uk

£17.99 (£1.80 / count)

£27.44 (£2.74 / count)

3M 8822 Disposable-fine dust mask FFP2 (10-pack)

Amazon.co.uk

£238.91

£360.17

Trend Portable Benchtop Router Table with Robust Construction for Workshop & Site Use, 240V, CRT/MK3

Amazon.co.uk

jimi43

Established Member

Thanks for the pictures Rod...

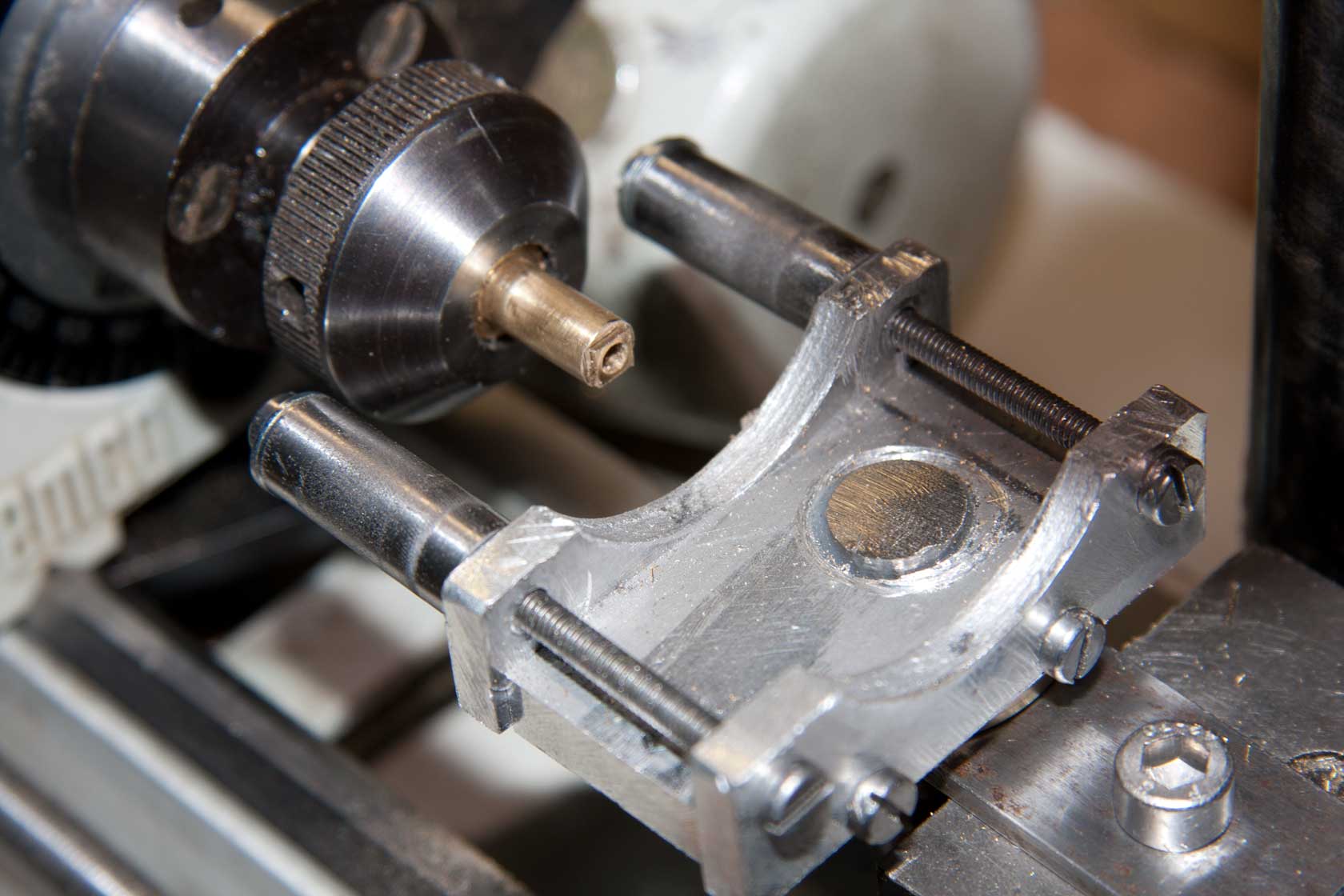

I can see that you set up a nice dividing plate there...I guess you need that many divisions for those many-geared cogs!

Thanks for sharing mate

Jim

I can see that you set up a nice dividing plate there...I guess you need that many divisions for those many-geared cogs!

Thanks for sharing mate

Jim

thanks for the pics, fascinating stuff.

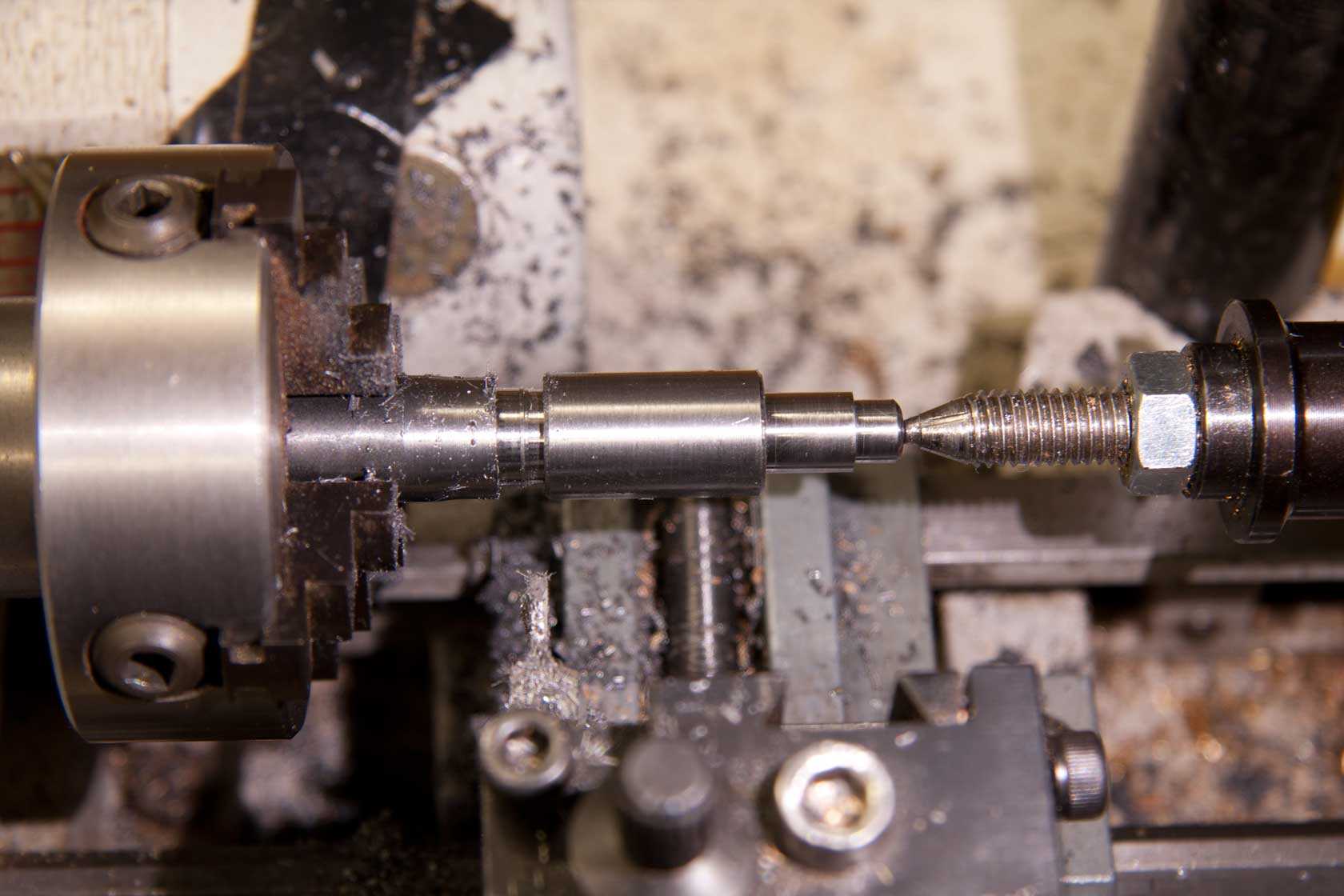

Marcros: a chuck is just one way of holding stock on a lathe. Collets and turning between centres (both shown in those photos above) are also common, and often more accurate too.

Marcros: a chuck is just one way of holding stock on a lathe. Collets and turning between centres (both shown in those photos above) are also common, and often more accurate too.

Marcros - I have a 3 and a 4 jaw chuck but for rods they are better held in a collet.

The picture of the Barrel Arbor shows the 4 jaw.

Jim - yes 100 divisions. My friend has a digital electronic dividing head now - takes all the fun out of it (I don't think! )

)

Rod

The picture of the Barrel Arbor shows the 4 jaw.

Jim - yes 100 divisions. My friend has a digital electronic dividing head now - takes all the fun out of it (I don't think!

Rod

jimi43

Established Member

And not cheap either I predict!

I have not seen the digital dividing units...interesting...will have to go and look. I assume it uses some sort of stepper motor?

Jim

I have not seen the digital dividing units...interesting...will have to go and look. I assume it uses some sort of stepper motor?

Jim

AES

Established Member

@Harbo,

Lovely looking work, thanks for all the pics.

Something I want to try "one of these fine wet days!", along with a wooden clock, and some woodwork tooling/jigs, and, and, and ................

Thanks for the inspiration.

AES

Lovely looking work, thanks for all the pics.

Something I want to try "one of these fine wet days!", along with a wooden clock, and some woodwork tooling/jigs, and, and, and ................

Thanks for the inspiration.

AES

Graham Orm

Established Member

WOW! =D> =D> =D>

Lons

Established Member

Hi Rod

That's fascinating. I'd love to try that one of these days but don't have the skill. I only very occasionally "play" with my little lathe. (it's a Cowell 90 ME. I thought they were well regarded but do they really fetch stupid prices?).

Can't wait to see the finished article. Keep posting please.

Bob

That's fascinating. I'd love to try that one of these days but don't have the skill. I only very occasionally "play" with my little lathe. (it's a Cowell 90 ME. I thought they were well regarded but do they really fetch stupid prices?).

Can't wait to see the finished article. Keep posting please.

Bob

Lons

Established Member

Harbo":26q72p5s said:Bob, sadly for me yes - old ones often fetch £800 plus!

They still make them but now over £2.5k plus VAT.

Rod

That's a real shock :shock:

Mine is almost mint I think and has a number of accessories. The old guy who bought it new was very well off and bought it on a whim then hardly used it. I did him a few favours over the years and was blown away when a number of years ago, he gifted it to me saying he knew I'd look after it.

I hope to use it but if not then at those prices I might be tempted to sell at some stage.

I'll take a photo tomorrow and post out of interest.

cheers

Bob

Lons

Established Member

Harbo":1mxbxus6 said:I'd like to come across somebody like that?Rod

I don't think there are many of them. Poor guy is departed this world now.

I first met him when he came into the dealership where I was manager and I sold him a DeWalt bandsaw at a decent discount and he bought all his tools from me after that. When I started my business I did quite a few paying jobs for him over a number of years but also helped him out several times without charge as I'm a great believer in what goes around, comes around but I never expected a gesture like that. He got too old to potter in his workshop and I was fitting replacement door locks for him when he just presented it to me. He wanted it to be looked after as he knew his son would just hock it asap and waste the money. Doesn't half prove there are genuine people around still.

I've just looked on the Cowells website and can't believe the prices, thanks for the heads up. I'll need to make something now as the last item was a small simple brass / rosewood trout priest

Bob

Similar threads

- Replies

- 1

- Views

- 415

- Replies

- 2

- Views

- 286

- Replies

- 5

- Views

- 774